A kind of acrylic pressure-sensitive adhesive tape and its preparation method and application

An acrylic pressure-sensitive adhesive tape, acrylic pressure-sensitive adhesive technology, applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-like adhesive, etc., can solve the problem of initial tack, stickiness, peel strength Balance, pressure-sensitive tape is easy to degumming, residual glue, low transparency and transparency, etc., to achieve good invisible effect, strong cohesion, and overcome the effect of degumming and residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

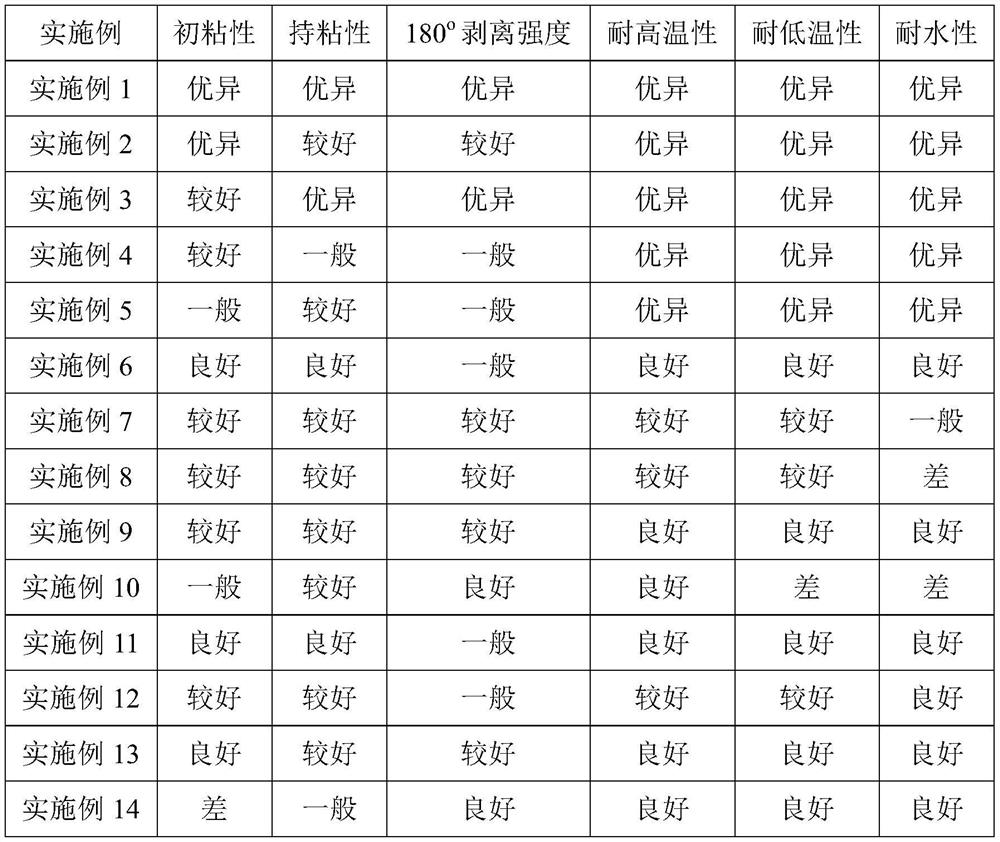

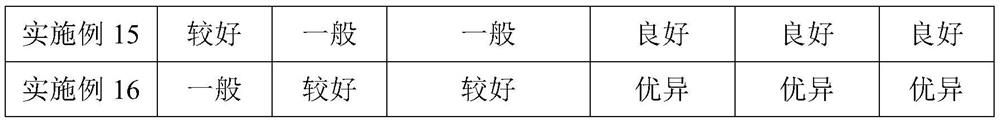

Examples

preparation example Construction

[0086] Among the present invention, the preparation method of described polyacrylic acid resin comprises the following steps:

[0087] (1) Add monomer Ⅰ, monomer Ⅱ and monomer Ⅲ into the reactor, stir evenly, add solvent, and heat up to 45-65°C while stirring in an inert gas environment;

[0088] (2) Add initiator, stir and heat up to 70°C-85°C, react until the solid content of the mixed material is 30%-70%, and the viscosity is 1000-50000cps, stop the reaction;

[0089] (3) Cool to below 40°C and discharge for later use.

[0090] The inventor believes that the best reaction temperature is preferably not lower than 80°C, preferably 85°C, and the transparency of the prepared glue solution is the best.

[0091] The viscosity test method is to use the NDJ-8S rotational viscometer produced by Shanghai Pingxuan Scientific Instrument Co., Ltd. to test against the GB / T2794-1995 standard.

[0092] The test method of glue solid content is:

[0093] Step 1: Cut the aluminum foil into...

Embodiment 1

[0118] Embodiment 1 provides a kind of acrylic pressure-sensitive adhesive tape, and described adhesive tape comprises substrate and the acrylic pressure-sensitive adhesive that is coated on one side of substrate; The other side of substrate is coated with release coating; Described substrate is PE Film, thickness is 0.07mm, purchased from Dongqiao Plastic Co., Ltd., Zhongshan City; the thickness of the release coating is 0.2 μm, and the material is a silicone release agent, purchased from Hubei New Sihai Chemical Co., Ltd.; the curing The agent is n-butanol etherified melamine formaldehyde resin, purchased from Shanghai Xinhua Resin Co., Ltd.;

[0119] The raw materials for the preparation of the acrylic pressure-sensitive adhesive include at least the following components in parts by weight: 80% polyacrylic resin, 16% tackifying resin, and 4% curing agent; the tackifying resin is olefin resin, vitrified The transformation temperature is 80±5°C, purchased from Shanghai Danfan...

Embodiment 2

[0130] Embodiment 2 provides a kind of acrylic pressure-sensitive adhesive tape, and described adhesive tape comprises substrate and the acrylic pressure-sensitive adhesive that is coated on one side of substrate; The other side of substrate is coated with release coating; Described substrate is PE Film, thickness is 0.065mm, purchased from Dongqiao Plastic Co., Ltd., Zhongshan City; the thickness of the release coating is 0.01 μm, and the material is a silicone release agent, purchased from Hubei New Universal Chemical Co., Ltd.; the curing The agent is n-butanol etherified melamine formaldehyde resin, purchased from Shanghai Xinhua Resin Co., Ltd.;

[0131] The raw materials for the preparation of the acrylic pressure-sensitive adhesive include at least the following components in parts by weight: 75% polyacrylic resin, 20% tackifying resin, and 5% curing agent; the tackifying resin is olefin resin, vitrified The transformation temperature is 80±5°C, purchased from Shanghai ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com