Lithium strip and preparation method and application thereof

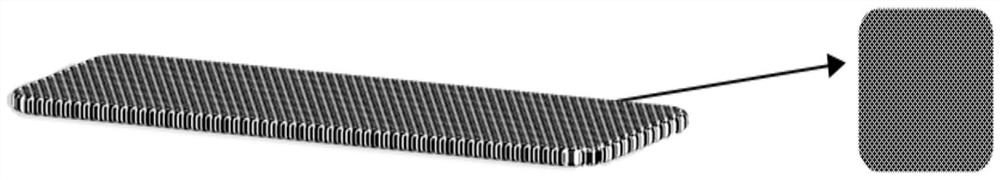

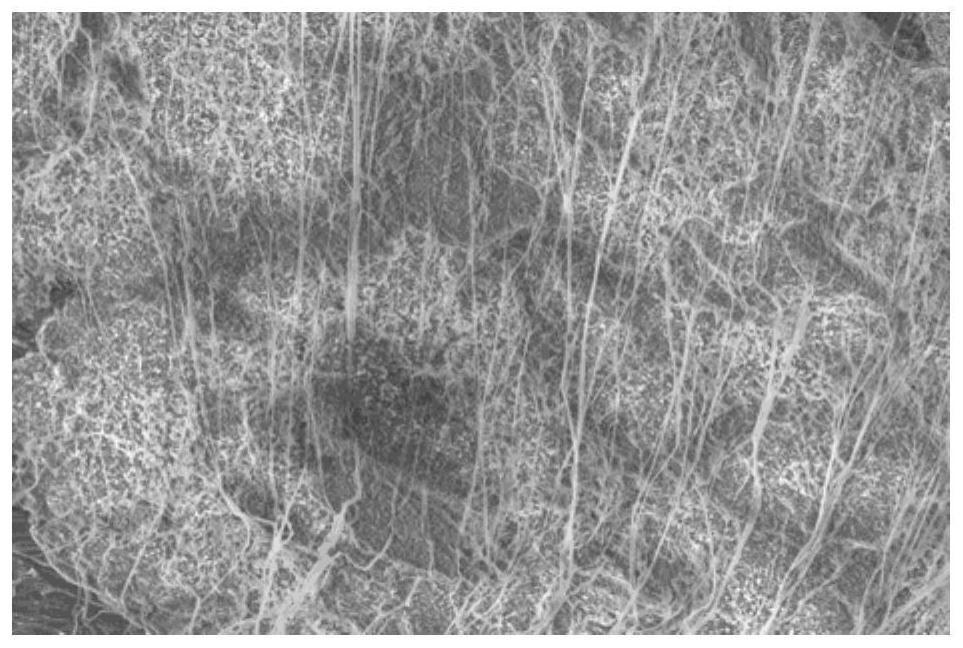

A technology for lithium strips and lithium supplementation, applied in electrode manufacturing, lithium storage batteries, electrode rolling/calendering, etc., can solve the problems of poor lithium metal strength, battery short circuit, and limit the large-scale use of lithium powder, and achieve enhanced strength, increased The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] In a drying room with a dew point less than -40°C, mix the lithium metal particle powder and PTFE (polytetrafluoroethylene), first at a stirring speed of 2000rpm, stirring and dispersing for 5 minutes, to fully mix the lithium metal powder and the polymer; Then carry out high-speed shear stirring at a speed of 20000rpm, adopt pulse type stirring, stirring time 1min, stop time 1min, stirring total time 20min, obtain dry process powder;

[0084] Wherein, the mass of the dry powder is 100%, and the dry powder includes the following components:

[0085] Lithium metal particle powder 95%

[0086] PTFE 5%;

[0087] Take a certain amount of dry powder and put it on the roller press equipment with adjustable roller gap. The rollers are cleaned and wiped with silicone oil to avoid sticking during the cold pressing process. The roller gap is 10μm and the speed is 5rpm. The rolling speed is 20°C to prepare a self-supporting lithium ribbon with a thickness of 13 μm;

[0088] Aft...

Embodiment 2

[0091] In a drying room with a dew point less than -40°C, mix the lithium metal particle powder and PTFE (polytetrafluoroethylene), first at a stirring speed of 2500rpm, stirring and dispersing for 5 minutes, to fully mix the lithium metal powder and the polymer; Then carry out high-speed shear stirring at a speed of 22000rpm, adopt pulse type stirring, stir for 1min, stop for 1min, and stir for a total of 20min to obtain a dry powder;

[0092] Wherein, the mass of the dry powder is 100%, and the dry powder includes the following components:

[0093] Lithium metal particle powder 90%

[0094] PTFE 10%;

[0095] Take a certain amount of dry powder and place it on the roller press equipment with adjustable roller gap. The rollers are cleaned and wiped with silicone oil to avoid sticking during the cold pressing process. The roller gap is 5 μm and the speed is 5 rpm. The rolling speed is 20°C to prepare a self-supporting lithium ribbon with a thickness of about 7 μm;

[0096] Th...

Embodiment 3

[0101] The difference between this embodiment and Example 1 is that, based on the mass of the dry powder as 100%, the dry powder includes the following components:

[0102] Lithium metal particle powder 10%

[0103] PTFE 90%;

[0104] Other parameters and conditions are exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com