Preparation method of catalyst for methanol fuel cell

A methanol fuel cell and catalyst technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of difficult large-scale industrial production of proton membrane fuel cells, low practical utilization efficiency of precious metals, and high cost of catalysts. Effect of improved tolerance, improved pore size, and high tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

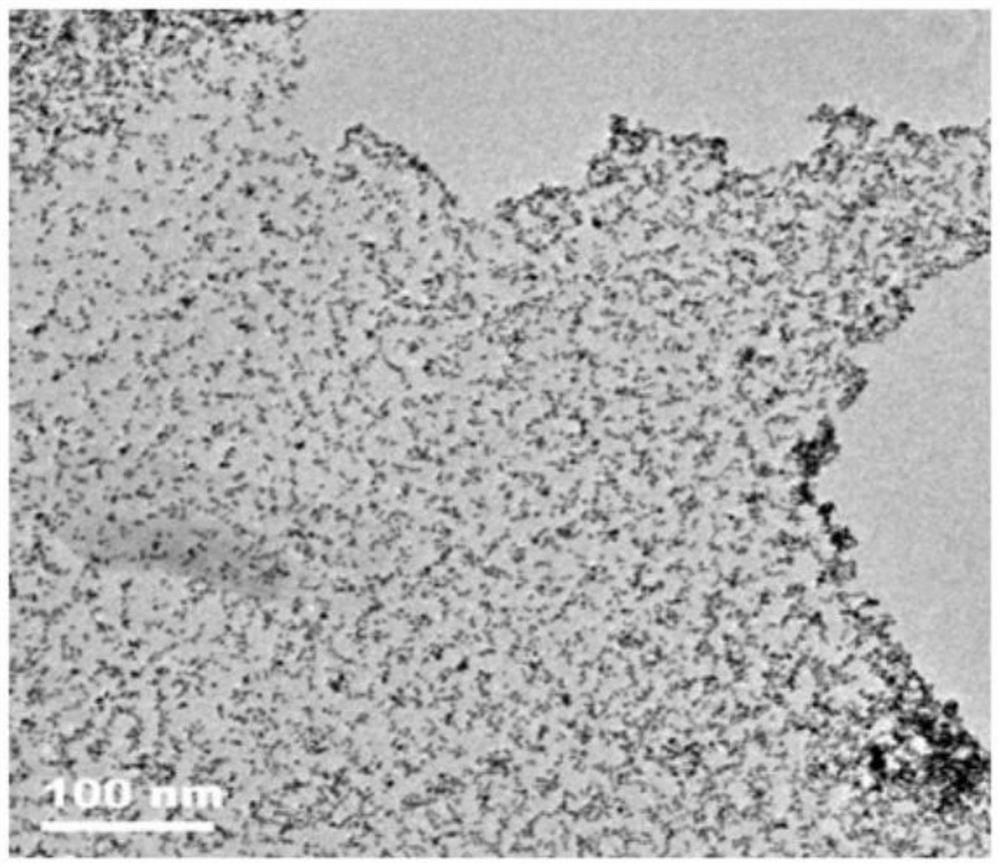

Image

Examples

Embodiment 1

[0021] A kind of catalyst that methanol fuel cell is used is prepared by following method:

[0022] Step 1: Dissolving 1 mol of porphyrin in acetonitrile, adding 1 mol of ferric chloride to dissolve it, heating to 60° C. and stirring for 4 hours, cooling and crystallizing to form a non-noble metal porphyrin complex;

[0023] Step 2: Dissolve 7g of ZIF8 in methanol to form a dispersion; dissolve 1g of cobalt chloride in methanol to form a solution, and slowly add the solution to the dispersion, first react at room temperature for 1 hour, and then heat up to 120°C React for 2 hours, after the reaction is over, cool to room temperature, and filter to obtain Co / Zn-MOFs;

[0024] Step 3: Disperse 5g of graphene in methanol, sonicate for 5 minutes, add 1g of Co / Zn-MOFs obtained in step 2, continue to sonicate for 10 minutes, in an inert atmosphere, heat up to 800°C for 6 hours, then cool to After room temperature, 2 g of the non-noble metal porphyrin complex obtained in step 1 was ...

Embodiment 2

[0027] A kind of catalyst that methanol fuel cell is used is prepared by following method:

[0028] Step 1: Dissolving 1.4 mol of porphyrin in acetonitrile, adding 1 mol of ferric chloride to dissolve it, heating to 65° C. and stirring for 4 hours, cooling and crystallizing to form a non-noble metal porphyrin complex;

[0029] Step 2: Dissolve 7g ZIF8 in methanol to form a dispersion; dissolve 1.4g of cobalt chloride in methanol to form a solution, and slowly add the solution to the dispersion, first react at room temperature for 1 hour, then heat up to 120 ℃ for 2.5 hours. After the reaction, cool to room temperature and filter to obtain Co / Zn-MOFs;

[0030] Step 3: Disperse 6g of graphene in methanol, sonicate for 8 minutes, add 1g of Co / Zn-MOFs obtained in Step 2, continue to sonicate for 12 minutes, in an inert atmosphere, heat up to 850°C for 7 hours, then cool to After room temperature, 2.4 g of the non-noble metal porphyrin complex obtained in step 1 was added, ultraso...

Embodiment 3

[0033] A kind of catalyst that methanol fuel cell is used is prepared by following method:

[0034] Step 1: Dissolving 1.8 mol of porphyrin in acetonitrile, adding 1 mol of ferric chloride to dissolve it, heating to 70° C. and stirring for 4.5 hours, cooling and crystallizing to form a non-noble metal porphyrin complex;

[0035] Step 2: Dissolve 7g ZIF8 in methanol to form a dispersion; dissolve 1.6g of cobalt chloride in methanol to form a solution, and slowly add the solution to the dispersion, first react at room temperature for 1 hour, then heat up to 120 ℃ for 3 hours, after the reaction, cooled to room temperature, and filtered to obtain Co / Zn-MOFs;

[0036] Step 3: Disperse 6.5g graphene in methanol, sonicate for 10 minutes, and add 1g of Co / Zn-MOFs obtained in step 2, continue to sonicate for 15 minutes, in an inert atmosphere, heat up to 900°C for 8 hours, then cool After reaching room temperature, 3 g of the non-noble metal porphyrin complex obtained in step 1 was a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com