Yoghurt powder freeze-dried yoghurt crisp product and preparation method thereof

A yogurt powder and freeze-drying technology, applied in dairy products, whey, applications, etc., can solve the problems of high product cost and short storage period, and achieve the effect of long shelf life, rich nutrition, and instant consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

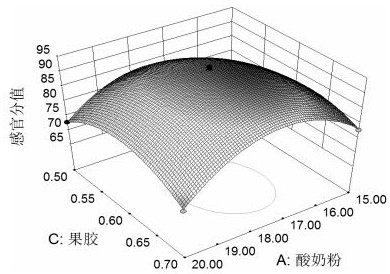

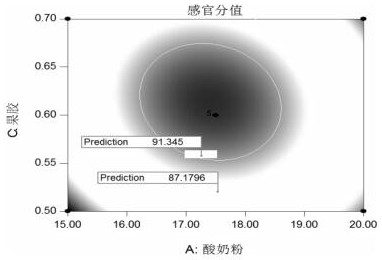

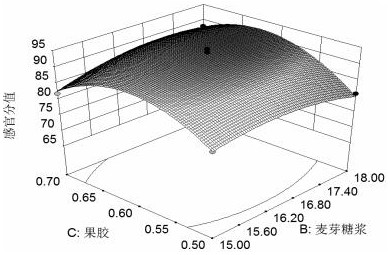

Image

Examples

Embodiment 1

[0026] Embodiment 1, a yogurt powder freeze-dried yogurt product, is made of the following raw materials in parts by weight:

[0027] Whole milk powder: 20 parts, rock sugar: 10 parts, yak milk powder: 5 parts, maltodextrin: 5 parts, malt syrup: 5 parts, yellow peach, blueberry, mango, apple and cranberry One or a mixture of several of them: 5 parts, desalted whey powder: 1 part, one or a mixture of two of corn starch and potato starch: 1 part, pectin: 0.1 part, CMC-Na carboxymethyl Sodium cellulose base: 0.1 parts, water: 250 parts.

[0028] The preparation method of above-mentioned yogurt powder freeze-dried yogurt product, concrete method step is as follows:

[0029] S1: Sieve the weighed whole milk powder, yak yoghurt milk powder, maltodextrin, desalted whey powder, cornstarch, and potato starch or a mixture of the two through a 60-mesh circular vibrating sieve, and dissolve In 35℃ water;

[0030] S2: Premix the weighed pectin and rock sugar, stir evenly, add 55°C water...

Embodiment 2

[0036] Embodiment 2, a yogurt powder freeze-dried yogurt product, is made of the following raw materials in parts by weight:

[0037] Skimmed milk powder: 30 parts, one or a mixture of brown sugar, white sugar, and glucose: 30 parts, yogurt powder made from goat milk or camel milk: 25 parts, maltodextrin: 15 parts, maltose syrup : 15 parts, pineapple grains, osmanthus grains, lily grains, raisin grains or a mixture of several: 10 parts, desalted whey powder: 6 parts, one or more of tapioca starch, yam starch, sweet potato starch Seed mixture: 6 parts, pectin: 0.8 parts, CMC-Na carboxymethylcellulose sodium: 0.2 parts, water: 350 parts.

[0038] The preparation method of above-mentioned yogurt powder freeze-dried yogurt product, concrete method step is as follows:

[0039] S1: Sieve the weighed yogurt powder, skimmed milk powder, maltodextrin, desalted whey powder, tapioca starch, yam starch, sweet potato starch or a mixture of several of them with a 60-mesh circular vibrating...

Embodiment 3

[0046] Embodiment 3, a yogurt powder freeze-dried yogurt product, is made of the following raw materials in parts by weight:

[0047]Mixture of whole milk powder and skimmed milk powder: 40 parts, a mixture of one or more of raffinose, lactose, arabinose, and maltose: 15 parts, one or more of goat milk, camel milk, and donkey milk Yogurt powder: 15 parts, maltodextrin: 25 parts, maltose syrup: 25 parts, pineapple grains, sweet-scented osmanthus grains, lily grains, raisin grains or a mixture of several: 3 parts, desalted whey powder : 3 parts, one or a mixture of tapioca starch, yam starch, sweet potato starch: 6 parts, pectin: 0.2 part, CMC-Na carboxymethyl cellulose sodium: 0.3 part, water: 300 parts.

[0048] The preparation method of above-mentioned yogurt powder freeze-dried yogurt product, concrete method step is as follows:

[0049] S1: Sieve the weighed yogurt powder, skimmed milk powder, maltodextrin, desalted whey powder, tapioca starch, yam starch, sweet potato sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com