Method for reinforcing recycled fine aggregate by bacillus pasteurii DSM33

A technology of Bacillus pasteurii and fine aggregate regeneration, which is applied in the intersection of building materials, microbiology and solid waste resource utilization, can solve the problem of limiting the scope of application of the modification process, increasing the potential cost of the modification process, and regenerating fine aggregates. There are few problems such as less aggregate modification, so as to reduce the cost of strengthening operation, improve the modification efficiency and effect, and have good stress resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] (1) Weigh 20 g of tryptone, 5 g of sodium chloride, 20 g of urea, and 1000 mL of deionized water to prepare a proliferation medium, and adjust the pH value to 9.5 by adding NaOH solution and HCl solution dropwise. After autoclaving at 121° C. for 20 minutes, Bacillus pasteurianus DSM33 was inoculated, shaken at 30° C. for 24 hours, and the shaking frequency was 130 rpm.

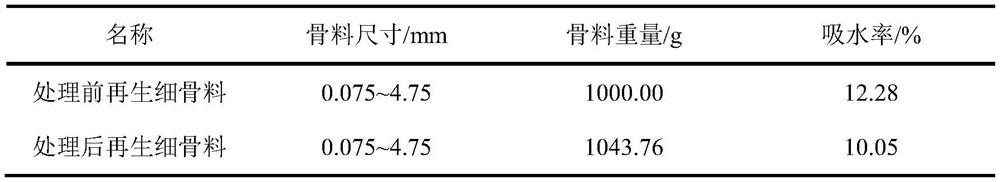

[0032] (2) Pass the regenerated fine aggregate through a 0.075mm sieve and wash it with water. The particle size ranges from 0.075mm to 4.75mm. Weigh 1000g and add it to 1L of the above-mentioned bacterial proliferation culture solution, and culture it statically at 30°C for 24h.

[0033] (3) Weigh 3 g of tryptone, 2.12 g of sodium carbonate, 5 g of ammonium chloride, 20 g of urea, 0.5 mol of calcium acetate, and 1000 mL of deionized water to prepare a precipitation medium. The above-mentioned regenerated fine aggregate was taken out from the bact...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] (1) Take 20 g / L tryptone, 5 g / L sodium chloride, and 20 g / L urea as standard to weigh and configure the proliferation medium, and adjust the pH value to 9.5 by adding NaOH solution and HCl solution dropwise. After autoclaving at 121° C. for 20 minutes, Bacillus pasteurianus DSM33 was inoculated, shaken at 30° C. for 24 hours, and the shaking frequency was 130 rpm.

[0042] (2) Prepare construction waste into recycled fine aggregate and wash it with water. The sieved particle size ranges from 0.6mm to 4.75mm. The ratio of aggregate to proliferation medium is 100g:100mL, and the aggregate is put into bacterial proliferation culture medium cultured at 30°C for 24 hours.

[0043] (3) Take tryptone 3g / L, sodium carbonate 2.12g / L, ammonium chloride 5g / L, urea 20g / L, calcium acetate 0.5mol / L as the standard and prepare the precipitation medium. The above-mentioned regenerated fine aggregate is taken out from the bacterial ...

Embodiment 3

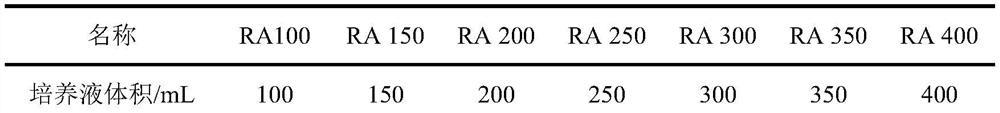

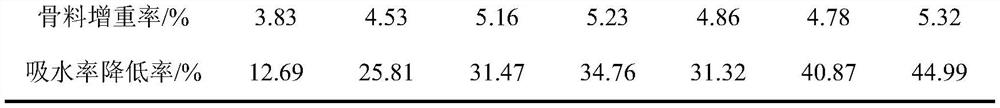

[0051] This embodiment includes the following steps:

[0052] (1) Take 20 g / L tryptone, 5 g / L sodium chloride, and 20 g / L urea as standard to weigh and configure the proliferation medium, and adjust the pH value to 9.5 by adding NaOH solution and HCl solution dropwise. After autoclaving at 121° C. for 20 minutes, Bacillus pasteurianus DSM33 was inoculated, shaken at 30° C. for 24 hours, and the shaking frequency was 130 rpm.

[0053] (2) The construction waste is prepared into recycled fine aggregate and washed with water, and the sieved particle size ranges from 0.075 mm to 4.75 mm, and is equally divided into two parts for later use. And take tryptone 3g / L, sodium carbonate 2.12g / L, ammonium chloride 5g / L, urea 20g / L, calcium acetate 0.5mol / L as the standard, weigh and configure the precipitation medium, set aside.

[0054] (3) The first aggregate is recorded as one-time modified aggregate, and the ratio of aggregate and proliferation medium is 100g:100mL. Put the aggregate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com