Thermal antibacterial school uniform fabric and preparation method thereof

A technology for fabrics and school uniforms, applied in the field of warming and antibacterial school uniform fabrics and its preparation, can solve the problem of poor comprehensive performance such as moisture absorption and perspiration performance, elastic wear resistance and mechanical strength, lack of comprehensive performance, warming and antibacterial school uniform fabrics, and easy mold Odor and other problems, to achieve the effect of good moisture absorption and perspiration performance, not easy to breed bacteria, and high antibacterial rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

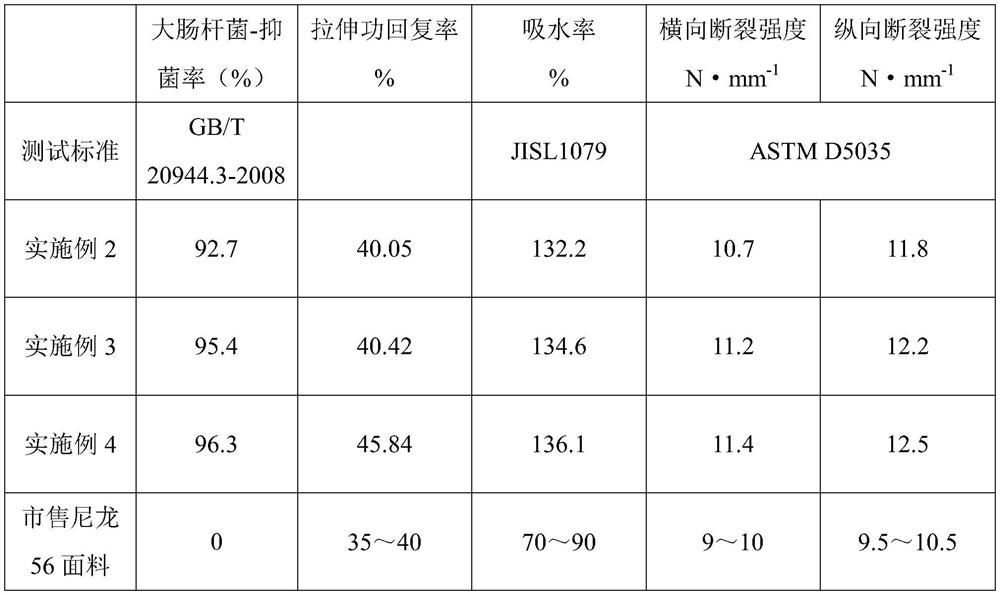

Examples

Embodiment 1

[0079] A warming and antibacterial school uniform fabric, the warming and antibacterial school uniform fabric is made of warming and antibacterial composite fiber through knitting or weaving process;

[0080] The warm-keeping and antibacterial composite fiber includes an inner layer and an outer layer;

[0081] The outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular;

[0082] The ratio of the cross-sectional area of the inner layer to the outer layer is 1:1.35-1.55;

[0083] The inner layer is made of raw materials comprising the following parts by weight:

[0084] Polyhexamethylene adipamide: 88-98 parts,

[0085] Polyurethane elastomer: 5-9 parts;

[0086] The outer layer is made of raw materials comprising the following parts by weight:

[0087] Nylon 56: 65-75 parts,

[0088] Polyhexamethylene adipamide: 15-20 parts,

[0089] Polyurethane elastomer: 20-28 parts,

[0090] 5-7 parts of airgel ...

Embodiment 2

[0133] A warming and antibacterial school uniform fabric, the warming and antibacterial school uniform fabric is made of warming and antibacterial composite fiber through knitting or weaving process;

[0134] The warm-keeping and antibacterial composite fiber includes an inner layer and an outer layer;

[0135] The outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular;

[0136] The ratio of the cross-sectional area of the inner layer to the outer layer is 1:1.35;

[0137] The inner layer is made of raw materials comprising the following parts by weight:

[0138] Polyhexamethylene adipamide: 88 parts,

[0139] Polyurethane elastomer: 5 parts;

[0140] The outer layer is made of raw materials comprising the following parts by weight:

[0141] Nylon 56: 65 parts,

[0142] Polyhexamethylene adipamide: 15 parts,

[0143]Polyurethane elastomer: 20 parts,

[0144] Airgel silica 5 parts,

[0145] 3 parts...

Embodiment 3

[0170] A warming and antibacterial school uniform fabric, the warming and antibacterial school uniform fabric is made of warming and antibacterial composite fiber through knitting or weaving process;

[0171] The warm-keeping and antibacterial composite fiber includes an inner layer and an outer layer;

[0172] The outer layer is coated on the outer surface of the inner layer, and the cross-sectional profile of the outer layer is circular;

[0173] The ratio of the cross-sectional area of the inner layer to the outer layer is 1:1.55;

[0174] The inner layer is made of raw materials comprising the following parts by weight:

[0175] Polyhexamethylene adipamide: 98 parts,

[0176] Polyurethane elastomer: 9 parts;

[0177] The outer layer is made of raw materials comprising the following parts by weight:

[0178] Nylon 56: 75 parts,

[0179] Polyhexamethylene adipamide: 20 parts,

[0180] Polyurethane elastomer: 28 parts,

[0181] Airgel silica 7 parts,

[0182] 4 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com