Inclined grating type polarization beam splitter applying slit waveguide structure and manufacturing method

A polarization beam splitter and tilted grating technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of restricting high-density chip integration, long directional coupler size, etc., and achieve small structure, low insertion loss, and high extinction than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

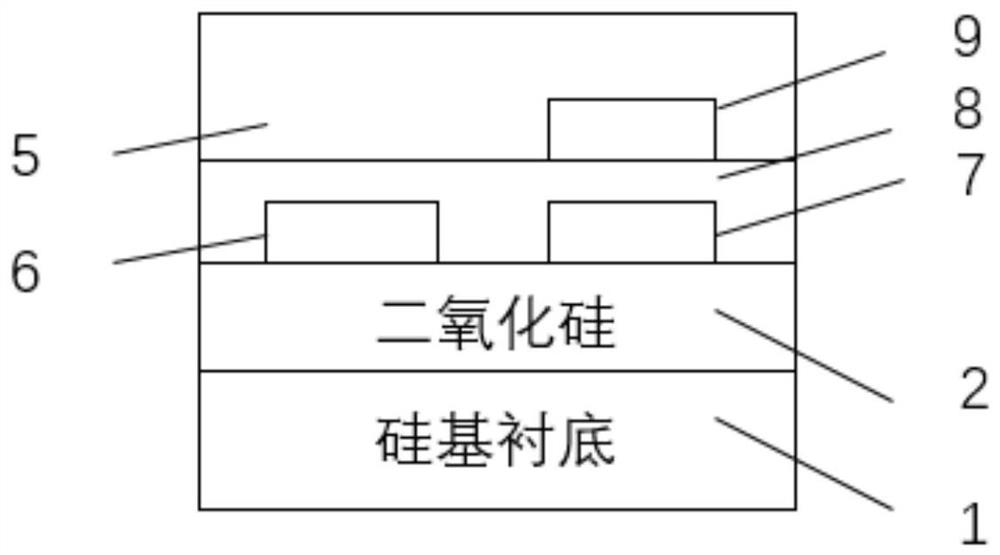

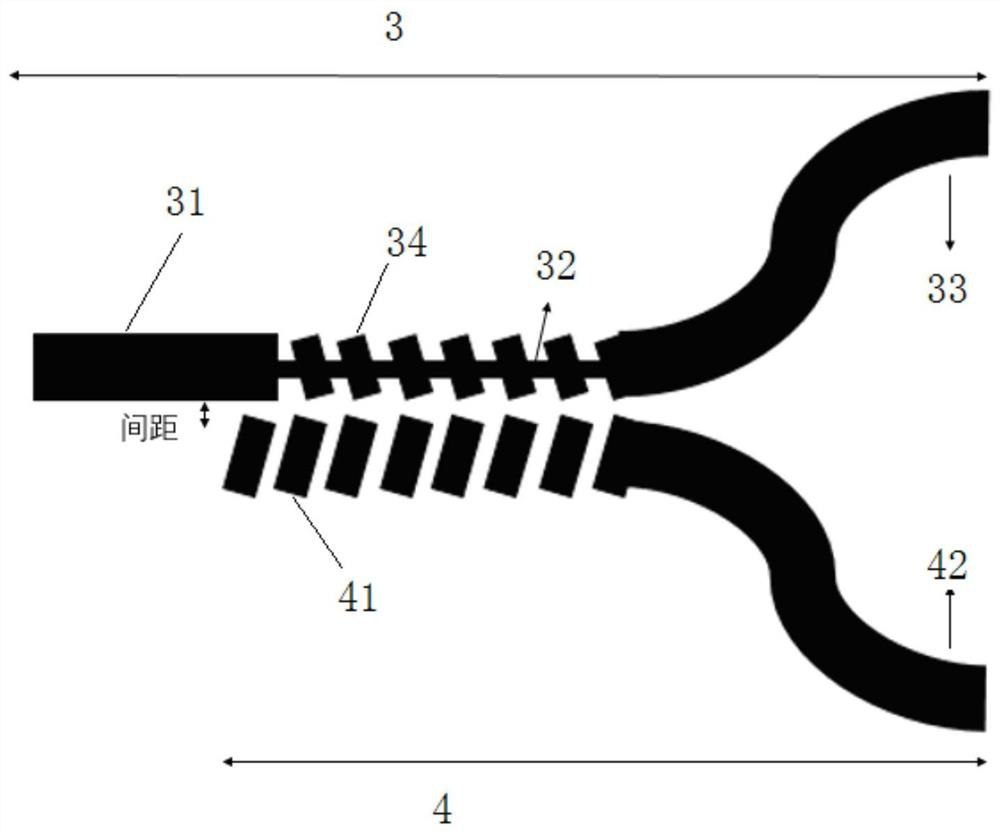

[0044] see Figure 1-4 , the tilted grating polarization beam splitter using the slit waveguide structure of the present invention, comprising: a silicon base substrate 1, a silicon dioxide buffer layer 2, a TE through section core layer 3, a TM coupling section core layer 4 and silicon dioxide Cladding 5.

[0045] A silicon dioxide buffer layer 2 is deposited on a silicon-based substrate 1 . The TE through section core layer 3 and the TM coupling section core layer 4 are located on the silicon dioxide buffer layer 2 and separated by a certain distance. The silicon dioxide cladding layer 5 is located on the silicon dioxide buffer layer 2 and covers the TE through-section core layer 3 and the TM coupling-section core layer 4 .

[0046] The TE through-section core layer 3 is based on the first silicon waveguide 6, and includes an input straight waveguide 31, a strip wavegu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com