Production system and production process of high-purity quartz raw material

A production system, quartz technology, applied in manufacturing tools, glass molding, silica, etc., can solve the problem of high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

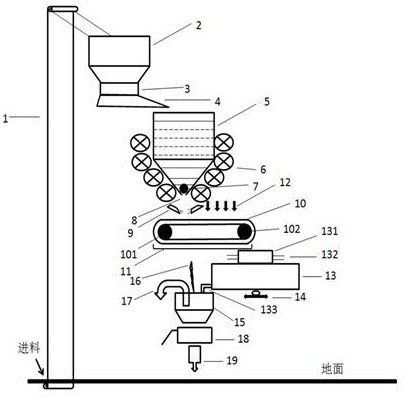

[0031] A production system for high-purity quartz raw materials, including a raw material conveying device, a heating and melting device, a melt cooling and conveying device, a pickling device, a centrifuge 15, a vacuum drying furnace 18 and a vacuum packaging machine 19; the raw material conveying device The discharge port of the heating and melting device is located above the feed port of the heating and melting device, the discharge hole of the heating and melting device is located above the melt cooling and transportation device, and the end of the melt cooling and transportation device is located at the Above the feed port of the pickling device, the discharge hole of the pickling device is connected with the feed port of the centrifuge through a pipeline, and the material outlet at the bottom of the centrifuge is connected with the feed port of the vacuum drying furnace through a pipeline, The discharge port of the vacuum drying furnace is connected with the feed port of ...

Embodiment 2

[0042] A kind of production technique of high-purity quartz raw material, utilizes the production system described in above-mentioned embodiment 1 to produce, specifically comprises the following processing steps:

[0043] (1) Feeding: The 3-4N quartz mineral raw material powder is lifted and transported to the kiln head silo by a bucket elevator, and the raw material powder is added into the crucible through the electromagnetic vibrating feeder arranged under the kiln head silo, and the continuous feeding time is based on The volume of the crucible and the length of melting and discharging time are determined, and all the raw material powder to be melted in the crucible is added at one time.

[0044] (2) Melting: Heating the crucible with plasma or high-frequency heating mode surrounding the middle and lower part of the crucible. The crucible is protected by vacuum or inert gas. The melting temperature is 2000-2200°C. After high-temperature melting, alkali and alkaline earth m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com