Oxazole group-containing quaternary ammonium salt side chain liquid crystal ionomer and preparation method thereof

A quaternary ammonium salt, oxazole-based technology, applied in the field of quaternary ammonium salt side chain liquid crystal ionomer and its preparation, can solve the problem of affecting the stability of liquid crystal ionomer and its application research, and it is difficult to obtain high molecular weight Problems such as ionomers and few ionized functional group sites in the main chain can achieve good output effects, improved ion conductivity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 A kind of quaternary ammonium salt side chain liquid crystal ionomer containing oxazole group and its preparation method

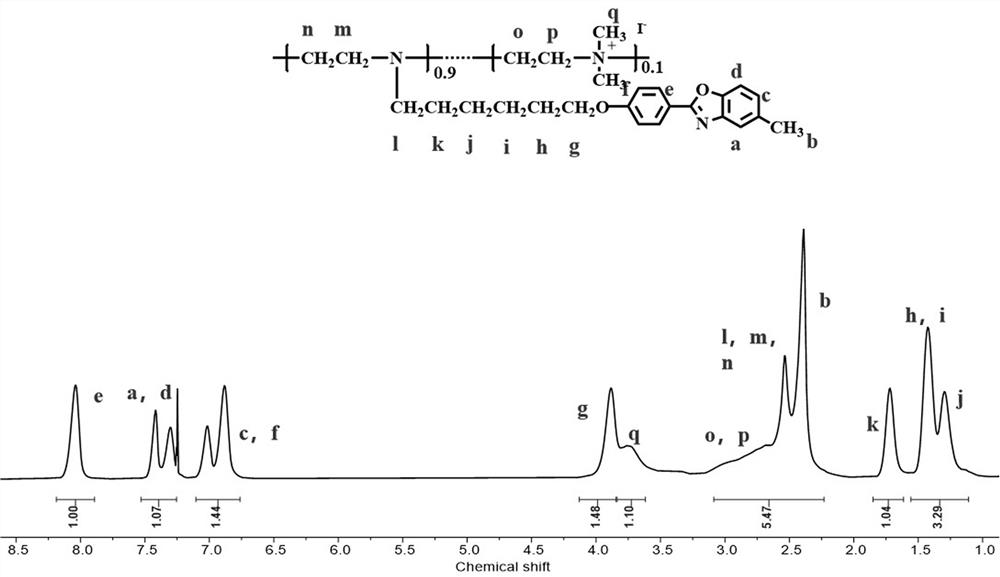

[0057]A kind of quaternary ammonium salt side chain liquid crystal ionomer containing oxazole group, its structural formula is as follows:

[0058]

[0059] In the formula, x+y=1, x=0.9, y=0.1.

[0060] The preparation method of the above-mentioned quaternary ammonium salt side chain liquid crystal ionomer containing oxazole group comprises the steps:

[0061] S1: Preparation of mesogens containing oxazole groups

[0062] Mix 5g (40.94mmol) of p-hydroxybenzaldehyde, 29.97g (122.82mmol) of 1,6-dibromohexane, 5.66g (40.94mmol) of potassium carbonate, and then add N,N-dimethyl 100 mL of methyl formamide, 80 ° C constant temperature reflux for 8 hours, after purification, the intermediate product A was obtained;

[0063] 9.34g (32.75mmol) of intermediate product A, 4.84g (39.30mmol) of 2-amino-4-methylphenol and 150mL of dichlorometha...

Embodiment 2-6

[0081] Embodiment 2-6 A kind of preparation method of quaternary ammonium salt side chain liquid crystal ionomer containing oxazole group

[0082] Embodiment 2-6 is respectively a kind of preparation method of quaternary ammonium salt side chain liquid crystal ionomer containing oxazole group, their steps are basically the same as the preparation method in Example 1, the difference is that in the preparation process Combined with the fine adjustment of common sense in the field and the difference of process parameters, the different process parameters are shown in Table 1:

[0083] Table 1 embodiment 2-6 technological parameter

[0084]

[0085]

[0086] Among them, in the oxazole group-containing quaternary ammonium salt side chain liquid crystal ionomer prepared in Example 2, x=0.77, y=0.23; the oxazole group-containing quaternary ammonium salt side chain liquid crystal ionomer prepared in Example 3 In the ionomer, x=0.8, y=0.2; x=0.84, y=0.16 in the quaternary ammoni...

Embodiment 7

[0087] Example 7 The structure, thermal behavior and electrical performance detection experiment of quaternary ammonium salt side chain liquid crystal ionomer containing oxazole group

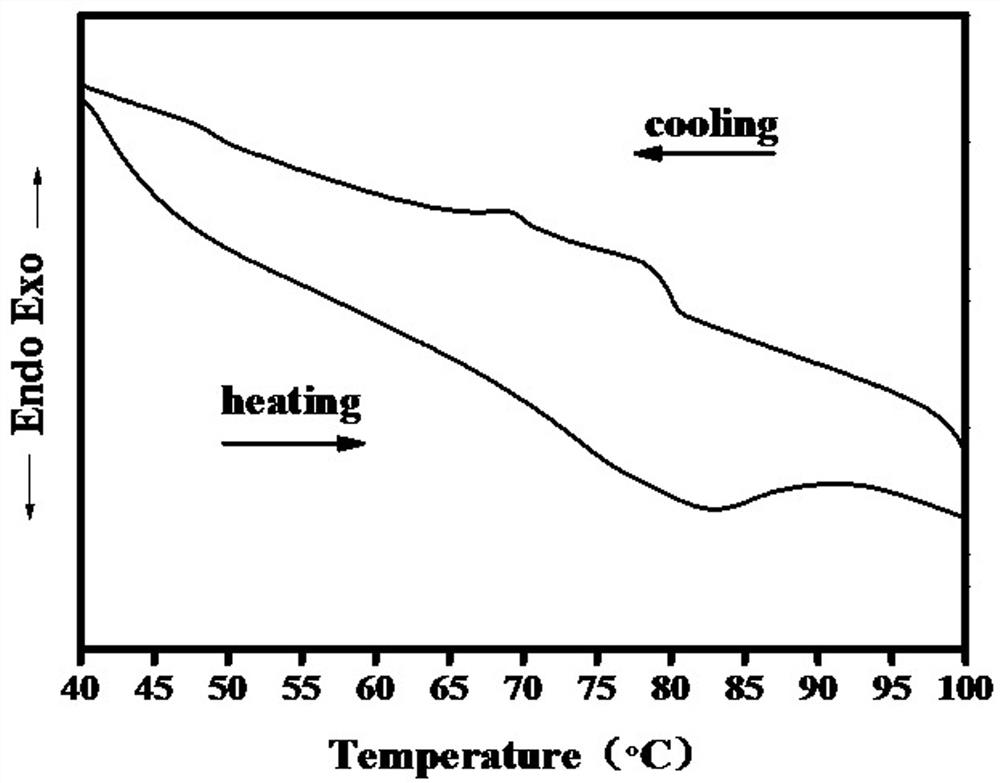

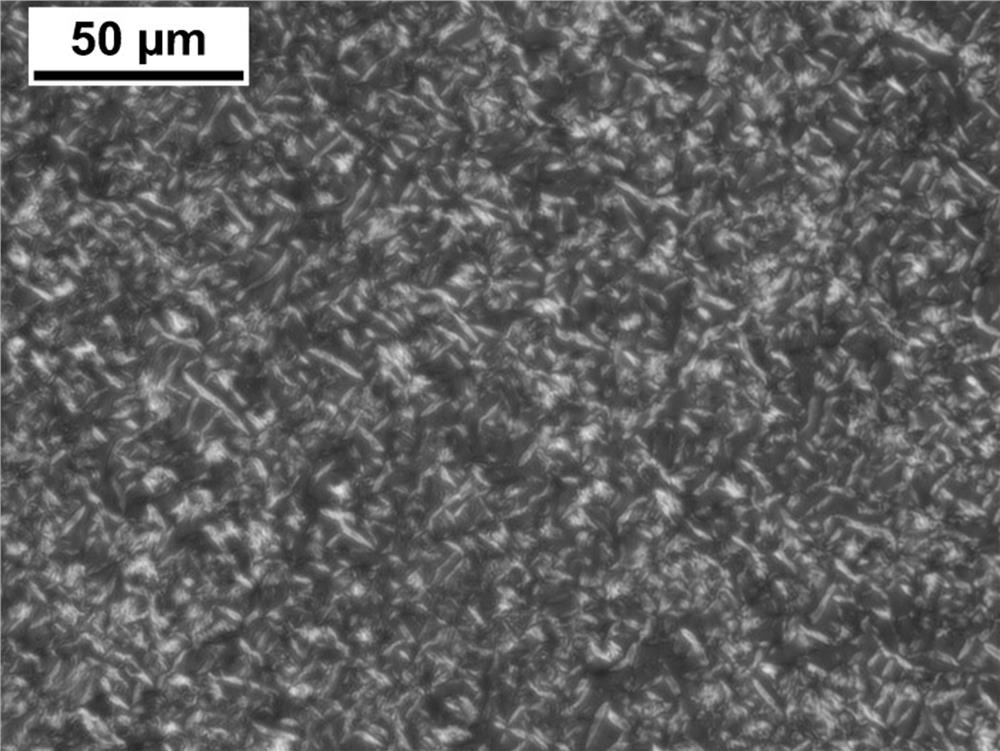

[0088] The structure, thermal behavior and electrical properties of the quaternary ammonium salt side chain liquid crystal ionomer containing oxazole groups prepared in Example 1 were determined, wherein the phase transition temperature and phase transition enthalpy were tested by differential scanning calorimeter ; The ionic conductivity is tested by an impedance meter. The result is as follows:

[0089] figure 1 It is the H NMR spectrum of the oxazole group-containing quaternary ammonium salt side chain liquid crystal ionomer prepared in Example 1. Depend on figure 1 It can be seen that the structure of the liquid crystal ionomer of the present invention is consistent with the expected idea.

[0090] Containing the oxazole group mesogen (6BrPBMe), the side chain polymer liquid crystal (PM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com