High-compression-resistance and high-bending-performance environment-friendly wood glue plate and preparation method thereof

A bending performance, wood plywood technology, applied in the field of wood plywood, can solve the problems of negative impact on the environment, high cost, harmful compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

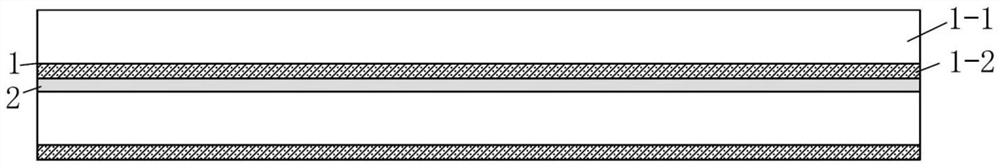

[0036] like figure 1 As shown, it is a high-compression and high-bending performance environmental protection wood glue board provided by this embodiment, the wood glue board includes a combination of multi-layer single-layer original wood board 1-1 and adhesive coating 1-2 Board unit 1, the plywood unit 1 is adhered by a polytetrafluoroethylene adhesive film 2 with a thickness of 0.03mm, and the thickness of the adhesive coating is 0.4mm;

[0037] The raw materials for the preparation of the adhesive coating 1-2, by weight components, include the following components:

[0038]

[0039] The number of layers of the plywood unit 1 in which the single-layer original wood board 1-1 is combined with the adhesive coating 1-2 is 2 layers.

[0040] Wherein, the preparation method of adhesive coating comprises the following steps:

[0041] S1: Mix 10 parts of aluminum silicate fiber with 25 parts of polyvinyl acetate resin, stir at 65°C at 100 rpm for 30 minutes, and continuously ...

Embodiment 2

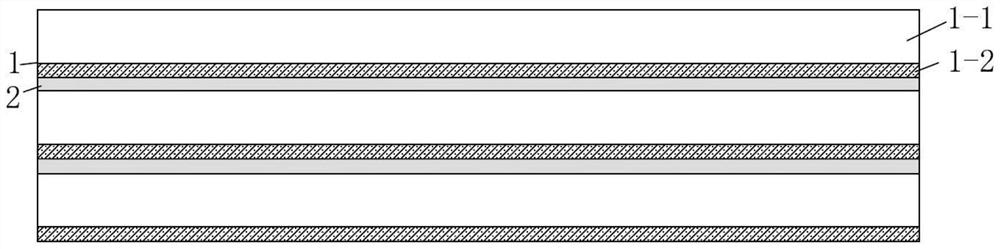

[0050] like figure 2 As shown, it is a high-compression-resistant and high-bending performance environmentally friendly wood plywood provided in this embodiment. The wood plywood includes a multi-layer single-layer original wood board 1-1 and an adhesive coating 1-1 with a thickness of 0.45mm. 2 combined plywood units 1, the plywood units 1 are bonded by a polytetrafluoroethylene adhesive film 2 with a thickness of 0.04mm;

[0051] The preparation raw materials of adhesive coating 1-2, by weight component, comprise following composition:

[0052]

[0053] The number of layers of the plywood unit 1 in which the single-layer original wood board 1-1 is combined with the adhesive coating 1-2 is 3 layers.

[0054] A method for preparing an adhesive coating, comprising the steps of:

[0055] S1: Mix 13 parts of gypsum fiber with 30 parts of polyvinyl acetate resin, stir at 70°C at 125 rpm for 37 minutes, and continuously add 7.5 parts of dimethylformamide dropwise during the s...

Embodiment 3

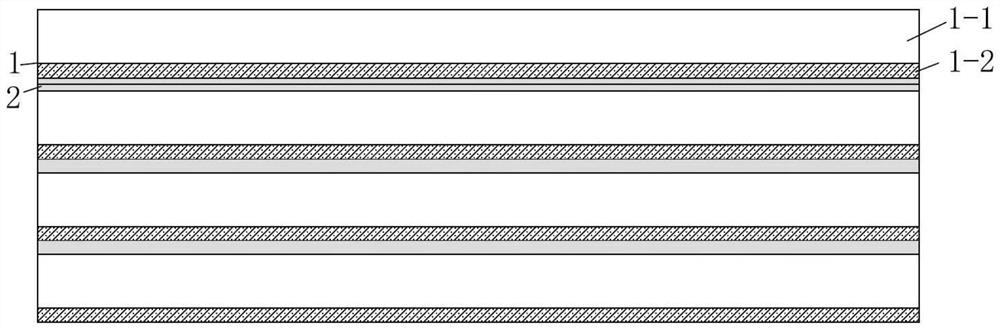

[0064] like image 3 As shown, it is a high-compression and high-bending performance environmental protection wood plywood provided in this embodiment, and the wood plywood includes a multi-layer single-layer original wood board 1-1 and an adhesive coating 1-1 with a thickness of 0.5 mm. 2 combined plywood units 1, the plywood units 1 are bonded by a polytetrafluoroethylene adhesive film 2 with a thickness of 0.05 mm;

[0065] The raw materials for the preparation of the adhesive coating include the following components by weight components:

[0066]

[0067] The plywood unit of the single-layer raw wood board 1-1 combined with the adhesive coating 1-2 has four layers.

[0068] The preparation method of described adhesive coating comprises the following steps:

[0069] S1: Mix 16 parts of basalt fiber with 35 parts of polyvinyl acetate resin, stir at 150 rpm for 45 minutes at 75°C, and continuously add 10 parts of dimethylformamide dropwise during the stirring process to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com