A kind of high compression resistance and high bending performance environmental protection wood plywood and preparation method thereof

A technology of bending performance and wood plywood, applied in the field of wood plywood, can solve problems such as high cost, negative impact on the environment, harmful compatibility, etc., and achieve the effect of improving adhesion, not easy to peel off, and increasing the degree of copolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

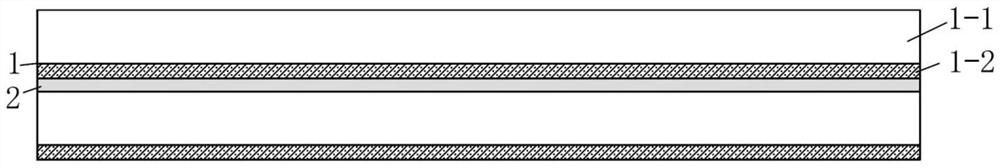

[0048] like figure 1As shown, it is a high-compression and high-bending performance environmental protection wood glue board provided by this embodiment, the wood glue board includes a combination of multi-layer single-layer original wood board 1-1 and adhesive coating 1-2 Board unit 1, the plywood unit 1 is adhered by a polytetrafluoroethylene adhesive film 2 with a thickness of 0.03mm, and the thickness of the adhesive coating is 0.4mm;

[0049] The raw materials for the preparation of the adhesive coating 1-2, by weight components, include the following components:

[0050] 10 parts of aluminum silicate fiber;

[0051] 25 parts of polyvinyl acetate resin;

[0052] Particle size is 18 parts of nanometer zinc oxide of 12nm;

[0053] 40 parts of polyurethane;

[0054] 5 parts of zinc diethyldithiocarbamate;

[0055] 12 parts of 2,6-di-tert-butyl-4-methylphenol antioxidant;

[0056] 3 parts of defoamer;

[0057] Leveling agent 4 parts;

[0058] 6 parts of isocyanate bri...

Embodiment 2

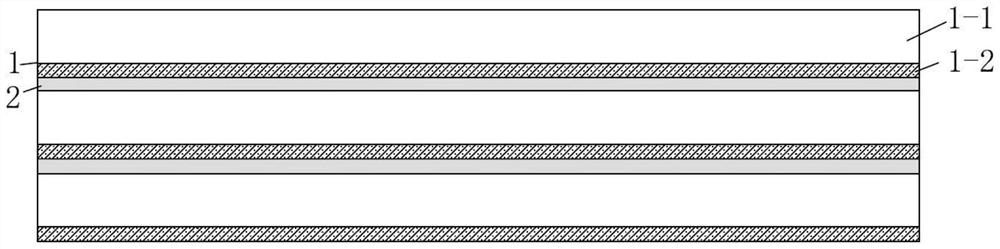

[0074] like figure 2 As shown, it is a high-compression-resistant and high-bending performance environmentally friendly wood plywood provided in this embodiment. The wood plywood includes a multi-layer single-layer original wood board 1-1 and an adhesive coating 1-1 with a thickness of 0.45mm. 2 combined plywood units 1, the plywood units 1 are bonded by a polytetrafluoroethylene adhesive film 2 with a thickness of 0.04mm;

[0075] The preparation raw materials of adhesive coating 1-2, by weight component, comprise following composition:

[0076] 13 parts of gypsum fiber;

[0077] 30 parts of polyvinyl acetate resin;

[0078] Particle size is 21.5 parts of nanometer zinc oxide of 15nm;

[0079] 45 parts of polyurethane;

[0080] 7 parts of zinc diethyldithiocarbamate;

[0081] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester antioxidant 13.5 parts;

[0082] 5 parts of defoamer;

[0083] Leveling agent 6 parts;

[0084] 8 parts of isoc...

Embodiment 3

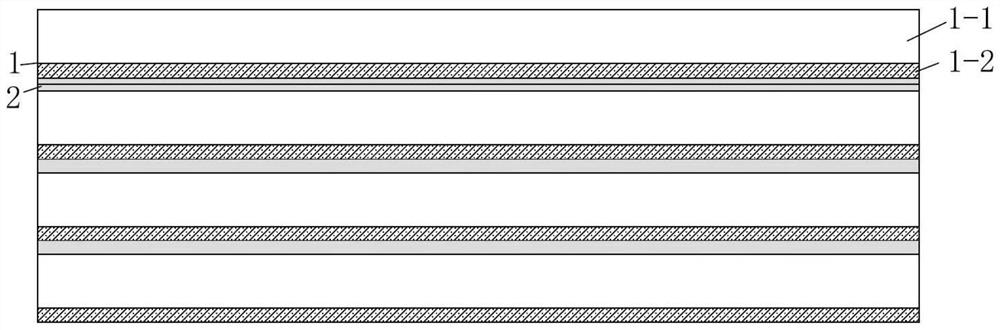

[0100] like image 3 As shown, it is a high-compression and high-bending performance environmental protection wood plywood provided in this embodiment, and the wood plywood includes a multi-layer single-layer original wood board 1-1 and an adhesive coating 1-1 with a thickness of 0.5 mm. 2 combined plywood units 1, the plywood units 1 are bonded by a polytetrafluoroethylene adhesive film 2 with a thickness of 0.05 mm;

[0101] The raw materials for the preparation of the adhesive coating include the following components by weight components:

[0102] Basalt fiber 16 parts;

[0103] 35 parts of polyvinyl acetate resin;

[0104] Particle size is 25 parts of nanometer zinc oxide of 18nm;

[0105] 50 parts of polyurethane;

[0106] 9 parts of zinc diethyldithiocarbamate;

[0107] 15 parts of 4,4'-(decaoxy-4,7-formaldehyde) bisphenol antioxidant;

[0108] 7 parts of defoamer;

[0109] Leveling agent 8 parts;

[0110] 10 parts of isocyanate bridging agent;

[0111] 12 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com