High-temperature insulating coating for battery and preparation method thereof

A high-temperature insulation and coating technology, applied in the direction of conductive coatings, secondary batteries, battery pack components, etc., can solve the problems of high initial internal resistance, reduced performance, temperature sensing time difference, etc., to achieve superior safety performance, increased internal resistance, Responsive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

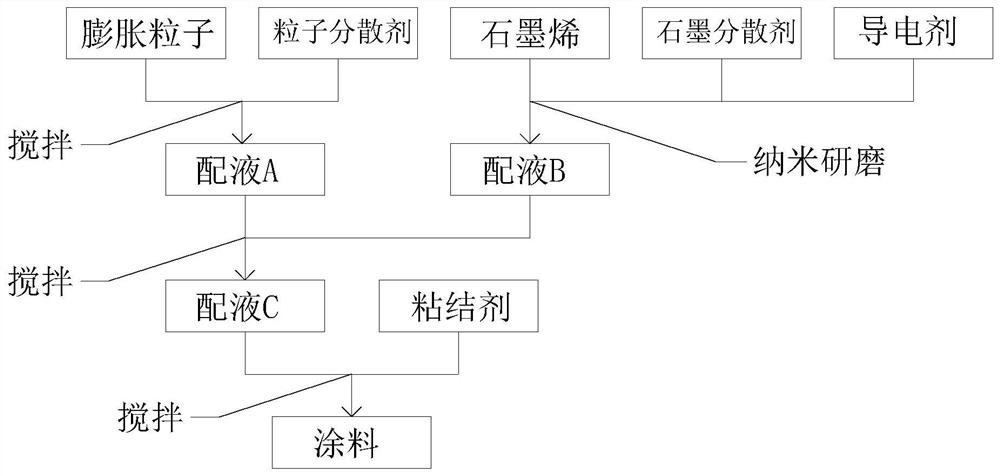

[0053] Specifically, the present application also provides a method for preparing a high-temperature insulating coating, comprising the following steps:

[0054](1) Mix the components in the first dosing with organic solvent or water in proportion and stir to obtain dosing A; mix the components in the second dosing with organic solvent or water in proportion and put into nano After grinding in the grinder, the formulation B is obtained;

[0055] (2) Mix the formulation A and the formulation B, and obtain the formulation C after stirring;

[0056] (3) Mix the formulation C and the binder in proportion to obtain the coating.

[0057] Further, the organic solvent can be esters, including ethyl acetate, butyl acetate, etc.; can be alkanes, including methane, ethane, propane, butane, pentane, etc.; can be alcohols, including methanol, ethanol, Isopropanol, n-butanol, etc.

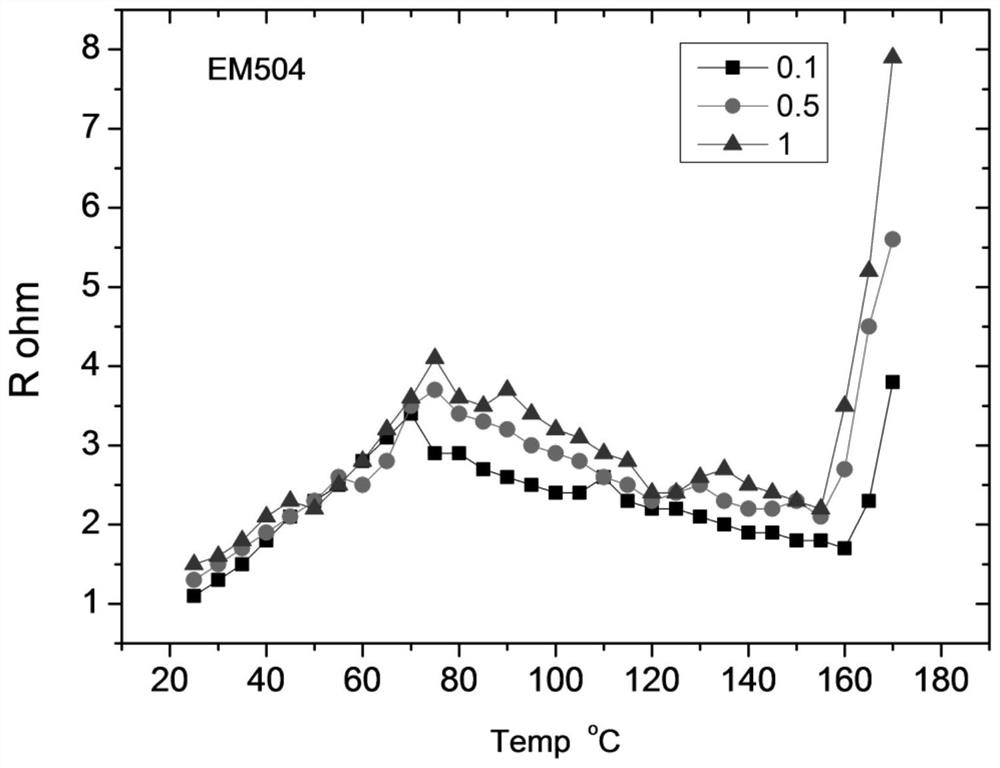

Embodiment 1

[0061] Prepare the raw materials of each component according to the following proportions:

[0062] (1) 1% expanded particles, 0.1% particle dispersant, 80% graphite component, 6% conductive agent, 2.9% graphite dispersant, and 10% binder;

[0063] (2) 5% of expanded particles, 1% of particle dispersant, 60% of graphite component, 7% of conductive agent, 7% of graphite dispersant, and 20% of binder;

[0064] (3) 10% of expanded particles, 2% of particle dispersant, 40% of graphite component, 8% of conductive agent, 10% of graphite dispersant, and 30% of binder;

[0065] The above expansion particles adopt EM504;

[0066] The specific operation steps are:

[0067] (1) Mix the expanded particles and the particle dispersant with the organic solvent, and stir to obtain the formulation A; mix the graphite component, the graphite dispersant, and the conductive agent in the organic solvent, and put them into a nano grinder for grinding, and the grinding time For 8 hours, after gri...

Embodiment 2

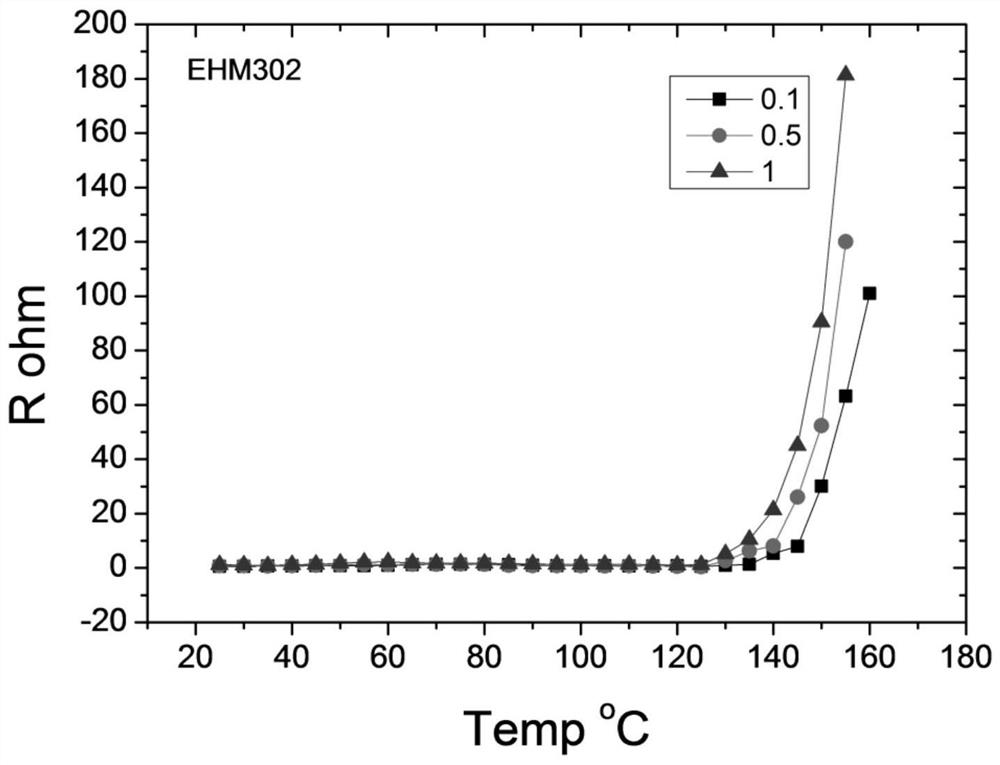

[0072] Refer to the proportioning in Example 1, and replace the expanded particle EM504 with EHM302, and refer to the specific operation method in Example 1 to obtain the variation of the surface internal resistance with temperature under different additions of the expanded particle EHM302. For details, please refer to see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com