Mxene flexible self-supporting lithium-air battery positive electrode material, preparation method thereof, Mxene flexible composite membrane and preparation method of Mxene flexible composite membrane

A battery cathode, self-supporting technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. The effect of high mechanical stability and easy transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of Mxene flexible self-supporting lithium-air battery cathode material, specifically comprising the following steps:

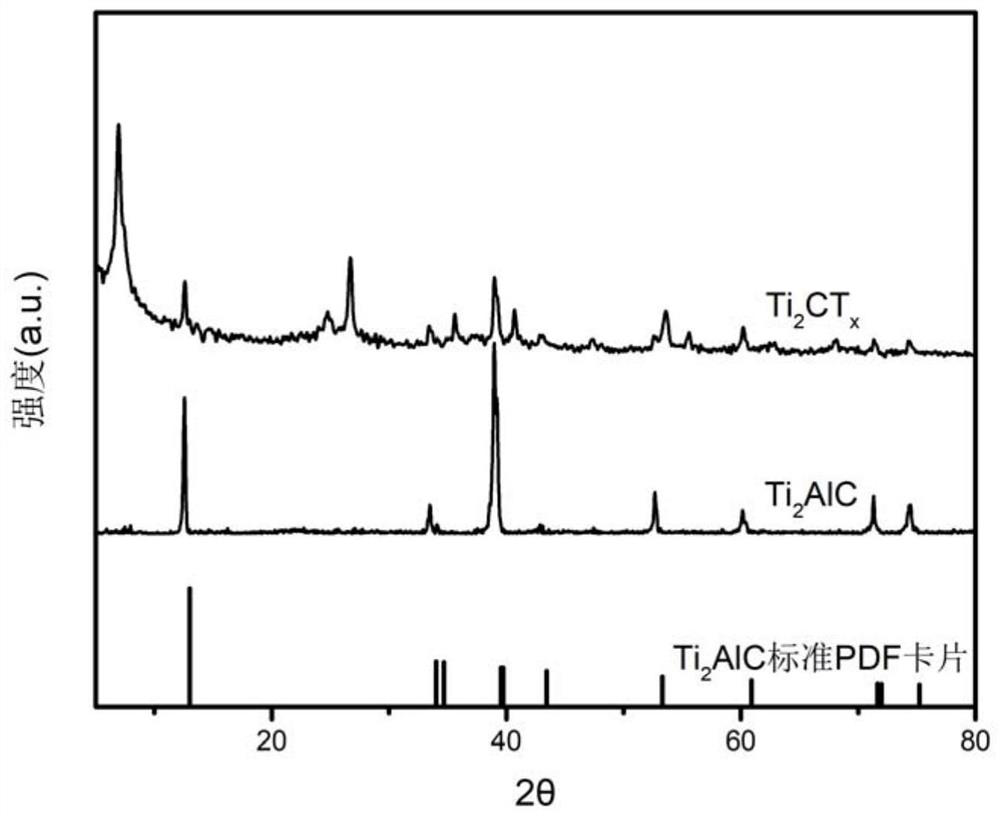

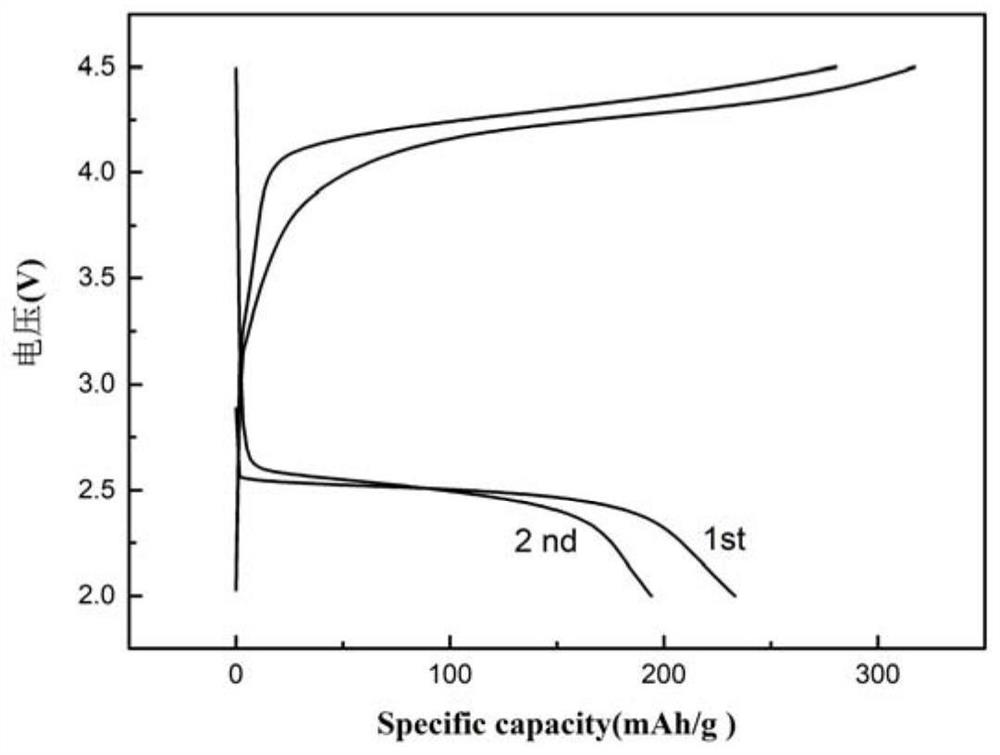

[0045] (1) Preparation of multilayer Mxene powder material: Dissolve 6g of lithium fluoride in 60mL with a concentration of 12molL -1 concentrated hydrochloric acid solution, mixed and stirred for 10 minutes to obtain a mixed etching solution. 2g Ti 2 AlC was slowly added to the mixed etching solution, stirred in a water bath at 40°C for 24 hours, and then centrifuged to obtain a precipitate. -1 The precipitate was washed several times with dilute hydrochloric acid solution to remove excess lithium fluoride, and then centrifuged and washed three times with deionized water. The obtained precipitate was vacuum-dried at 25°C for 48 hours to obtain a multilayer Mxene powder material. The multilayer Mxene powder material is Ti 2 CT x , where T x One or more of -OH functional group / -F functional group / -O functional group. Ti 2 AlC ...

Embodiment 2

[0054] A preparation method of Mxene flexible self-supporting lithium-air battery cathode material, specifically comprising the following steps:

[0055] (1) Preparation of multi-layer Mxene powder material: Slowly add 1g MAX phase ceramic material into 10mL hydrofluoric acid solution, the concentration of hydrofluoric acid is 40%, stir at room temperature for 24h, centrifuge to obtain precipitate, and then wash repeatedly with deionized water 5 times, the obtained precipitate was vacuum-dried at 25°C for 48 hours to obtain a multi-layer Mxene powder material. The multilayer Mxene powder material is Ti 2 CT x , where T x One or more of -OH functional group / -F functional group / -O functional group.

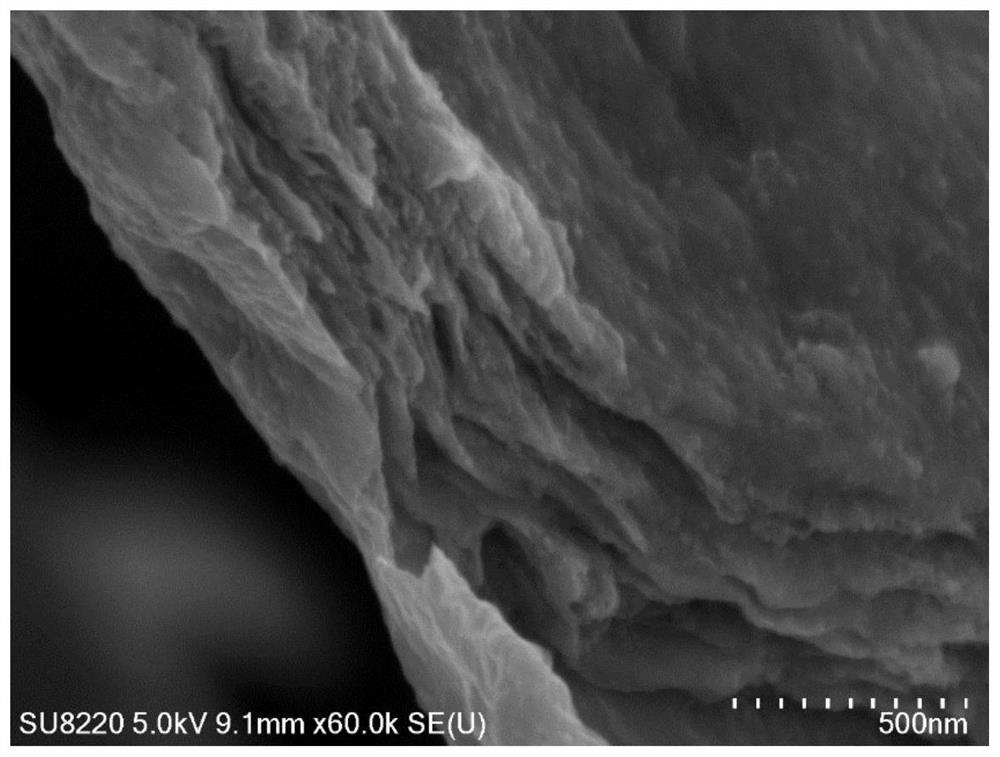

[0056] The prepared multilayer Mxene powder material has a good layered structure, and the lamellar stacking is serious. Due to the functional groups (OH, F, O) in the adsorbed state on Ti 2 CT x The surface is randomly distributed and there are interactions between layers.

...

Embodiment 3

[0063] A preparation method of Mxene flexible self-supporting lithium-air battery cathode material, specifically comprising the following steps:

[0064] Add 1g lithium fluoride to 10mL 12mol L -1 hydrochloric acid solution, and then slowly add 1gTi Ti while stirring 2 AlC. After the addition was complete, the mixture was stirred in a water bath for 24 h at 35° C. to obtain multilayer Mxene (multilayer Ti 2 CT x Powder material) dispersion liquid, washed 4-5 times with deionized water until the pH is about 6. Afterwards, it was subjected to ultrasonic treatment for 1 h, and centrifuged at 3500 rpm for 1 h to remove the sediment at the bottom to obtain a Mxene dispersion with few layers peeled off. Vacuum filtration was performed with a Celgard 3501 diaphragm to form a flexible Mxene film, followed by vacuum drying at 80°C for 6 hours to obtain a flexible self-supporting electrode of Mxene.

[0065] Such as Figure 4 As shown, the prepared multilayer Ti 2 CT x The powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com