Anti-aging repair day cream and preparation method thereof

A technology of mass parts and mixtures, which is applied in the field of daily chemicals, can solve the problems of declining anti-aging effects, achieve the effects of reducing skin fine lines, protecting the skin barrier and hydration function, and enhancing skin firmness and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

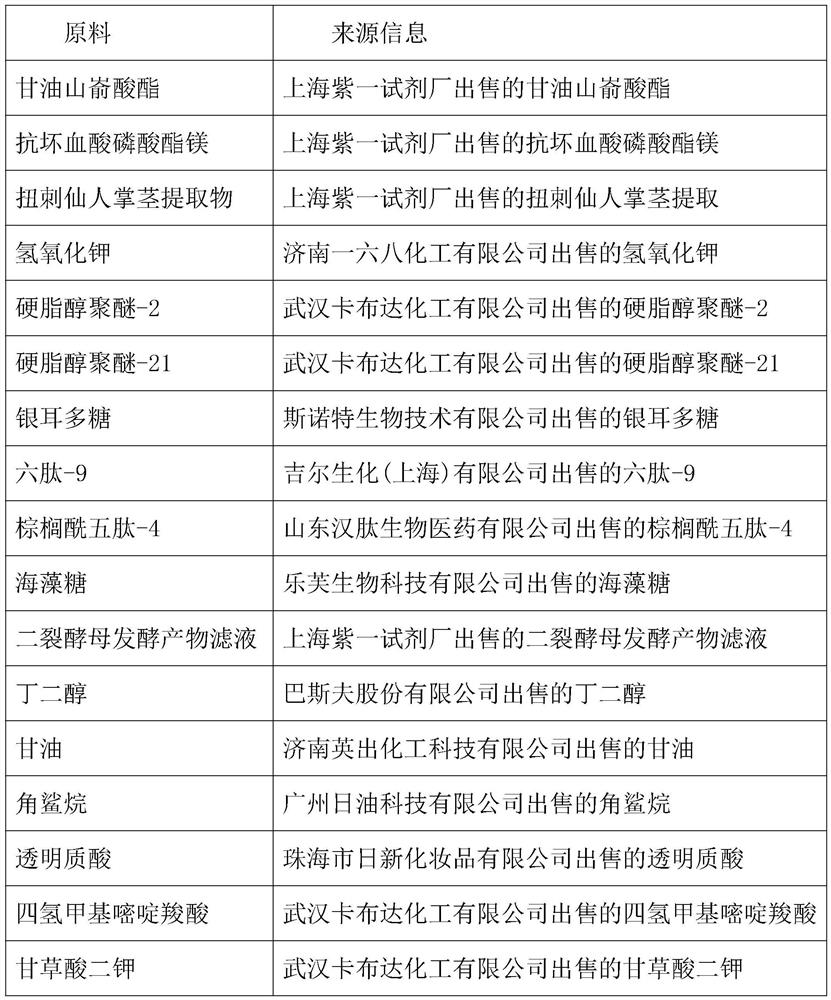

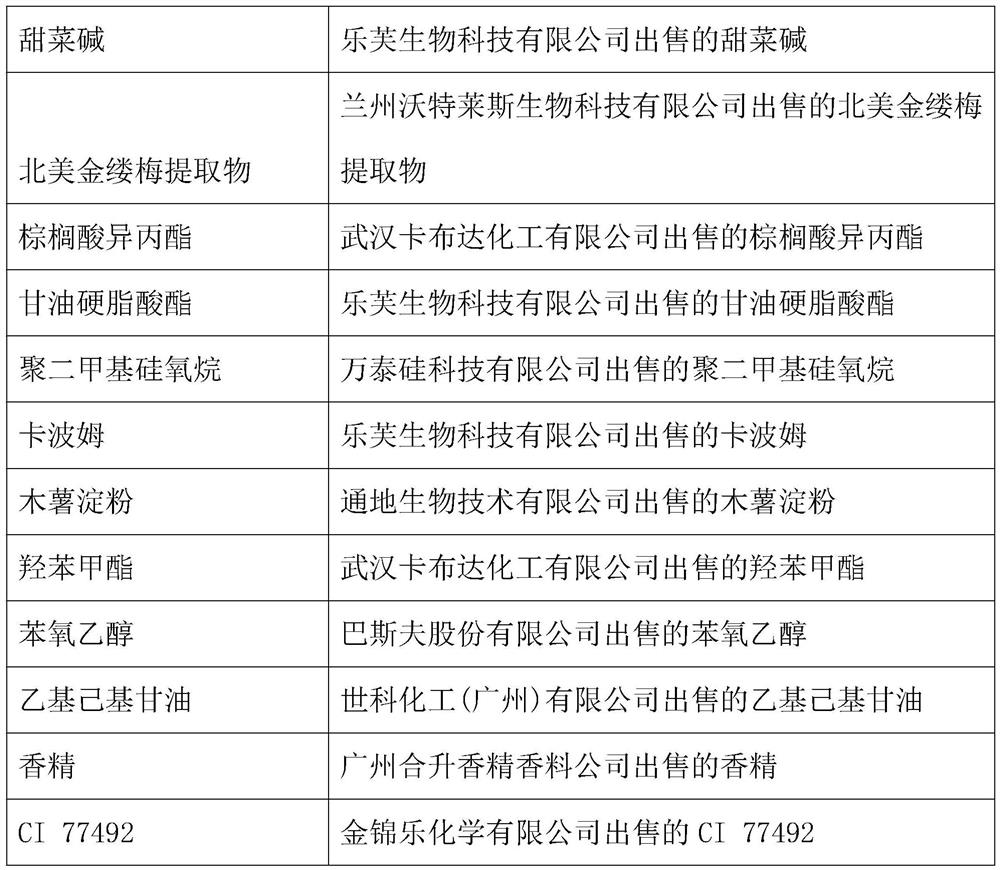

[0079] Embodiment 1-4: a kind of anti-aging repair day cream, comprises following component:

[0080] Deionized water, glyceryl behenate, magnesium ascorbyl phosphate, prickly pear stem extract, pH adjuster and emulsifier.

[0081] The pH regulator is potassium hydroxide.

[0082] The emulsifier is a compound of steareth-2 and steareth-21.

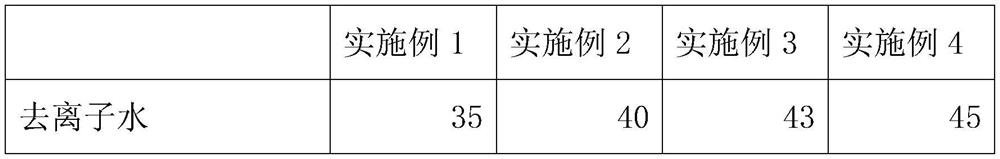

[0083] In embodiment 1-4, the input amount (unit Kg) of each component sees table 2 for details

[0084] Table 2

[0085]

[0086]

[0087] The preparation method of the anti-aging repair day cream of embodiment 1-4 comprises the following steps:

[0088] Step 1), adding potassium hydroxide and deionized water into the stirred tank, heating to 50°C while stirring, rotating at 25r / min, and stirring for 2min to obtain the first mixture;

[0089] Step 2), adding magnesium ascorbyl phosphate and cactus thorn stem extract into the stirring tank, heating to 50°C while stirring with the first mixture, stirring at a speed of 90r / min, and...

Embodiment 5

[0093] Compared with embodiment 2, the difference only lies in:

[0094] In step 1), potassium hydroxide is mixed with deionized water and heated to 40°C.

[0095] In step 2), magnesium ascorbyl phosphate, cactus twirl stem extract and the first mixture are stirred at 40°C.

[0096] In step 3), the stirring temperature was 80°C.

[0097] In step 4), cool down to 40°C, and homogenize for 4 minutes under a pressure of 0.08Mpa.

Embodiment 6

[0099] Compared with embodiment 2, the difference only lies in:

[0100] In step 1), potassium hydroxide is mixed with deionized water and heated to 60°C.

[0101] In step 2), magnesium ascorbyl phosphate, cactus twirl stem extract and the first mixture are stirred at 60°C.

[0102] In step 3), the stirring temperature was 90°C.

[0103] In step 4), the temperature was lowered to 60° C., and homogenized under a pressure of 0.12 Mpa for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com