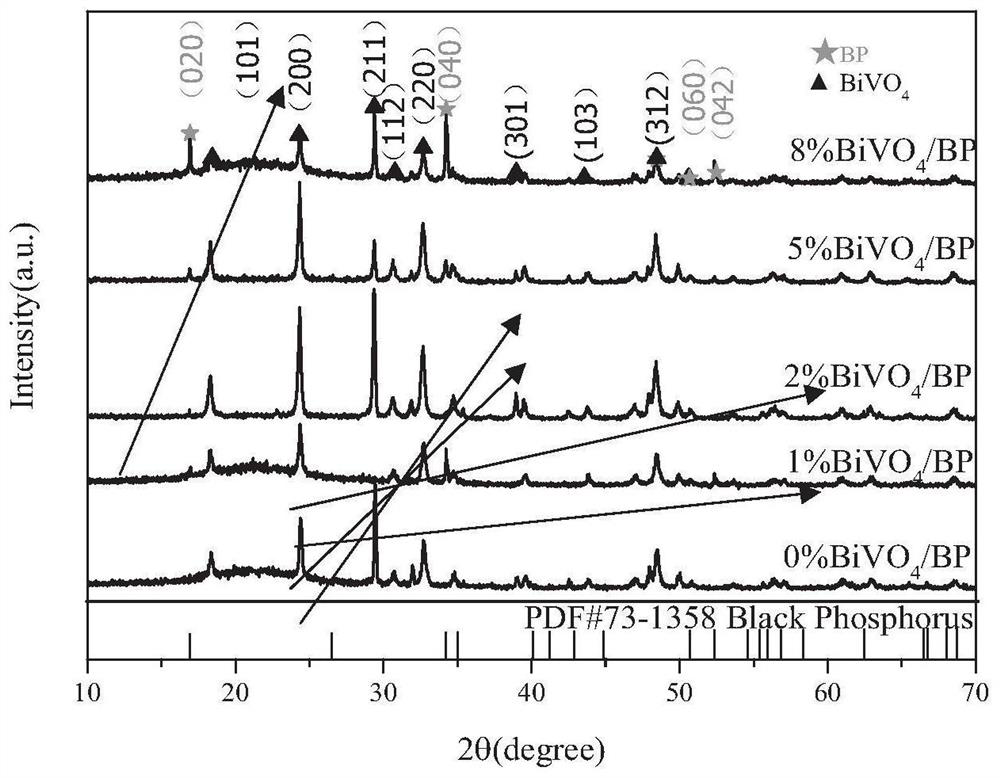

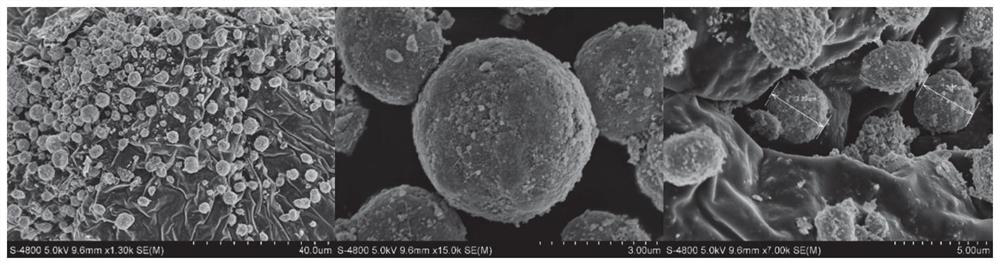

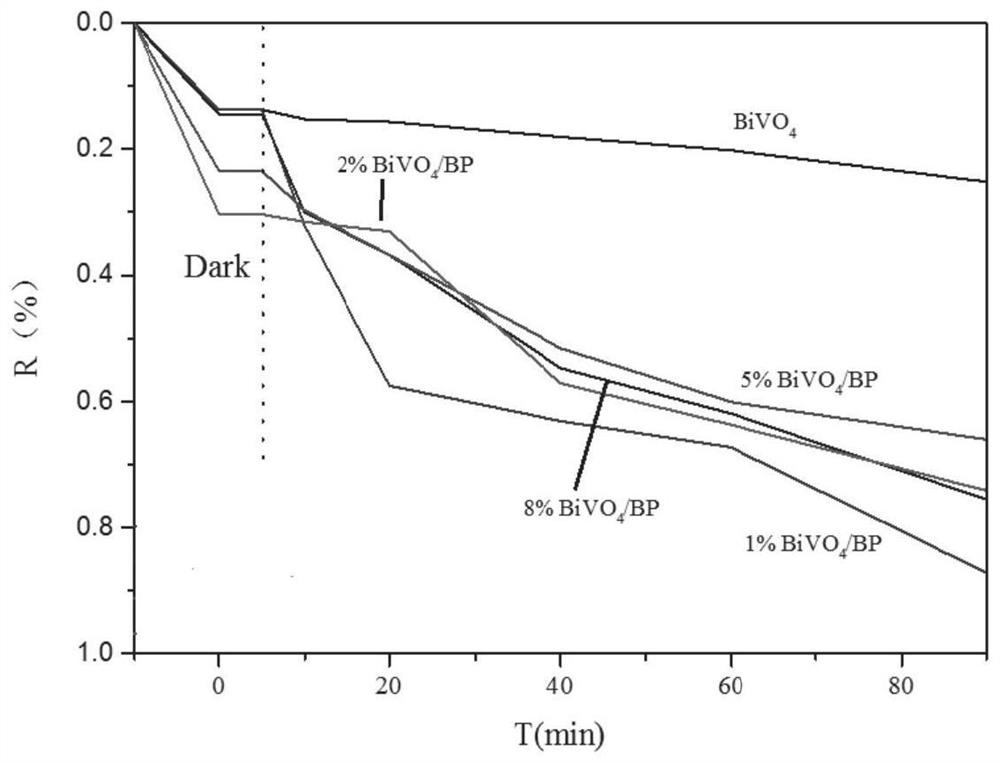

Spherical bismuth vanadate/black phosphorus composite photocatalyst and preparation method thereof

A bismuth vanadate and catalyst technology, applied in the field of photocatalysis, can solve the problems of a single semiconductor photocatalyst, achieve excellent photocatalytic performance, improve stability, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the specific steps for preparing spherical bismuth vanadate / black phosphorus composite photocatalytic material are as follows:

[0040] (1) 3.94g Bi(NO 3 ) 3 ·5H 2 O dissolved in 5 mL of concentrated HNO 3 Add water and dilute to 20mL (4mol / L), stir slowly for 10min to obtain solution A;

[0041] (2) Then 1.16g NH 4 VO 3 Dissolve in 20mL 4mol / L NaOH solution, stir evenly to obtain solution B; under constant stirring condition, slowly add solution B dropwise to solution A, at the same time adjust the pH of the mixed solution to 5.0 with 2mol / L NaOH, continue magnetic stirring After 30 minutes;

[0042] (3) Transfer the mixture of step (2) to a water bath for a constant temperature reaction at 100°C for 24 hours;

[0043] (4) After natural cooling, remove the supernatant, vacuum filter and wash with deionized water and absolute ethanol several times until neutral, dry at 80°C for 12 hours, and grind with an agate mortar for later use to obtain a...

Embodiment 2

[0049] In this embodiment, the specific steps for preparing spherical bismuth vanadate / black phosphorus composite photocatalytic material are as follows:

[0050] (1) 3.94g Bi(NO 3 ) 3 ·5H 2 O dissolved in 5 mL of concentrated HNO 3 Add water and dilute to 20mL (4mol / L), stir slowly for 10min to obtain solution A;

[0051] (2) Then 1.16g NH 4 VO 3 Dissolve in 20mL 4mol / L NaOH solution, stir evenly to obtain solution B; under constant stirring condition, slowly add solution B dropwise to solution A, at the same time adjust the pH of the mixed solution to 5.0 with 2mol / L NaOH, continue magnetic stirring After 30 minutes;

[0052] (3) Transfer the mixture of step (2) to a water bath for a constant temperature reaction at 100°C for 24 hours;

[0053] (4) After natural cooling, remove the supernatant, vacuum filter and wash with deionized water and absolute ethanol several times until neutral, dry at 80°C for 12 hours, and grind with an agate mortar for later use to obtain a b...

Embodiment 3

[0059] In this embodiment, the specific steps for preparing spherical bismuth vanadate / black phosphorus composite photocatalytic material are as follows:

[0060] (1) 3.94g Bi(NO 3 ) 3 ·5H 2 O dissolved in 5 mL of concentrated HNO 3 Add water and dilute to 20mL (4mol / L), stir slowly for 10min to obtain solution A;

[0061] (2) Then 1.16gNH 4 VO 3 Dissolve in 20mL 4mol / L NaOH solution, stir evenly to obtain solution B; under constant stirring condition, slowly add solution B dropwise to solution A, at the same time adjust the pH of the mixed solution to 5.0 with 2mol / L NaOH, continue magnetic stirring After 30 minutes;

[0062] (3) Transfer the mixture of step (2) to a water bath for a constant temperature reaction at 100°C for 24 hours;

[0063] (4) After natural cooling, remove the supernatant, vacuum filter and wash with deionized water and absolute ethanol several times until neutral, dry at 80°C for 12 hours, and grind with an agate mortar for later use to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com