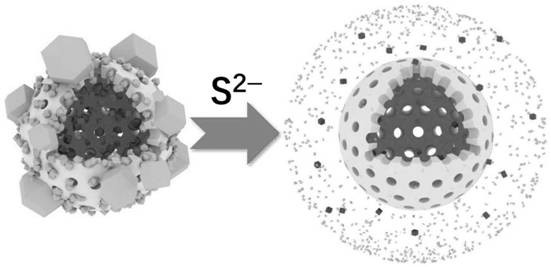

Sulfur ion response type nano container and application

A technology of nano-container and sulfide ion, applied in the direction of application, nanotechnology, nanotechnology, etc., can solve the problems of failure to realize intelligent protection against microbial corrosion, achieve good research and development application prospects, avoid coating performance damage, avoid coating The effect of shortening the service life of layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

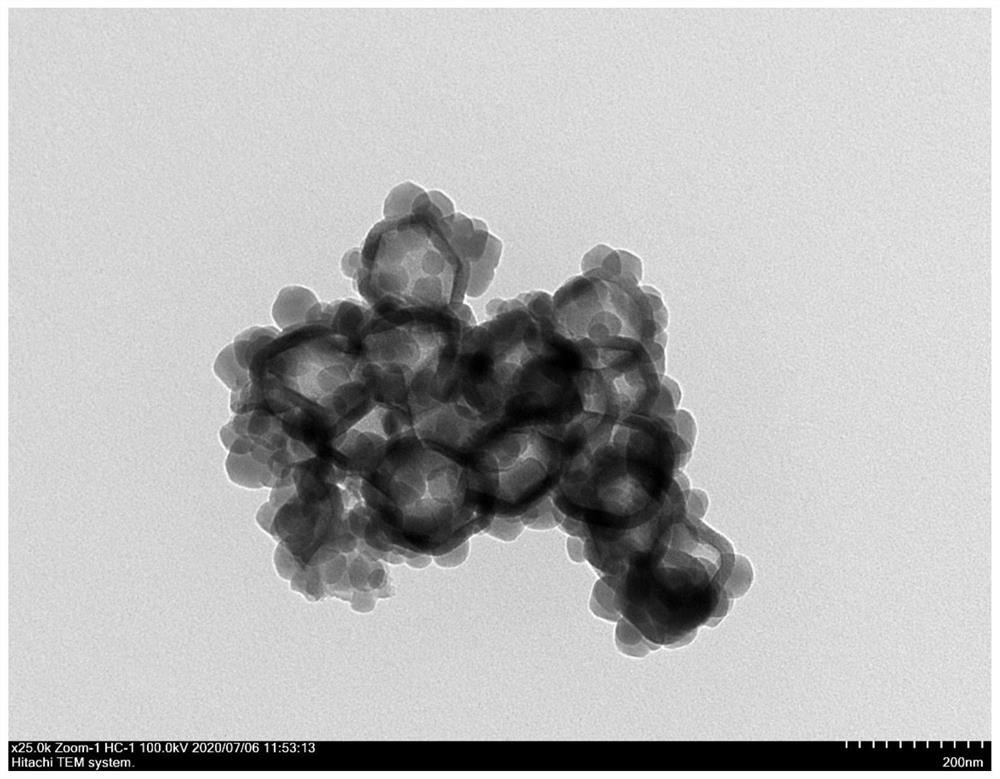

[0048] (1) Preparation of ZIF-8 template

[0049] Weigh 1.5g zinc nitrate hexahydrate and dissolve it in 100mL methanol to obtain a methanol solution (solution A) of 15g / L zinc nitrate; weigh 3.3g 2-methylimidazole and dissolve it in 100mL methanol to obtain a concentration of 33g / L L 2-methylimidazole methanol solution (solution B), pour solution A into solution B and mix, stir at 2000rpm / min for 60min to react, centrifuge, wash with methanol 3 times, dry at 60°C overnight to obtain ZIF- 8 nanoparticles.

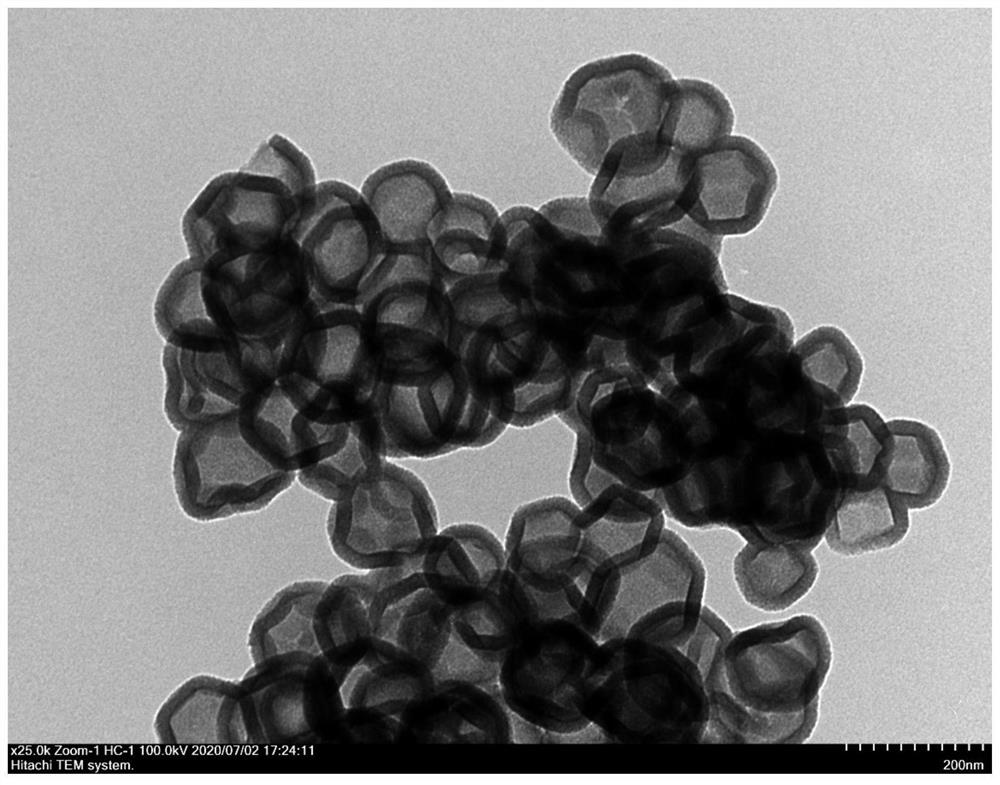

[0050] (2) Preparation of HMSNs

[0051] Measure 540mL of a mixed solution of deionized water and absolute ethanol, wherein the volume ratio of water and absolute ethanol is 5:4; weigh 0.5g of ZIF-8 solid powder and disperse it in the mixed solution, and ultrasonicate for 30min; weigh 1.6g Dissolve cetyltrimethylammonium bromide in the above dispersion, and stir at room temperature for 30 minutes; measure 400 μL of 0.05 M sodium hydroxide solution into the above solution,...

Embodiment 2

[0059] (1) Preparation of ZIF-8 template

[0060] Weigh 3g of zinc nitrate hexahydrate and dissolve it in 100mL of methanol to obtain a methanol solution (solution A) of 30g / L zinc nitrate; weigh 6.6g of 2-methylimidazole and dissolve it in 100mL of methanol to obtain a concentration of 66g / L 2-Methylimidazole methanol solution (solution B), pour solution A into solution B and mix, stir at 2000rpm / min for 60min to react, centrifuge, wash with methanol 3 times, dry at 60°C overnight to obtain ZIF-8 nanoparticles.

[0061] (2) Preparation of HMSNs

[0062] Measure 540mL of a mixed solution of deionized water and absolute ethanol, wherein the volume ratio of water and absolute ethanol is 5:4; weigh 0.5g of ZIF-8 solid powder and disperse it in the mixed solution, and ultrasonicate for 30min; weigh 1.6g Dissolve cetyltrimethylammonium bromide in the above dispersion, and stir at room temperature for 30 minutes; measure 400 μL of 0.1M sodium hydroxide solution into the above soluti...

Embodiment 3

[0071] (1) Preparation of ZIF-8 template

[0072] Weigh 4.5g zinc nitrate hexahydrate and dissolve it in 100mL methanol to obtain a methanol solution (solution A) of 45g / L zinc nitrate; weigh 9.9g 2-methylimidazole and dissolve it in 100mL methanol to obtain a concentration of 99g / L L 2-methylimidazole methanol solution (solution B), pour solution A into solution B and mix, stir at 2000rpm / min for 60min to react, centrifuge, wash with methanol 3 times, dry at 60°C overnight to obtain ZIF- 8 nanoparticles.

[0073] (2) Preparation of HMSNs

[0074] Measure 540mL of a mixed solution of deionized water and absolute ethanol, wherein the volume ratio of water and absolute ethanol is 5:4; weigh 0.5g of ZIF-8 solid powder and disperse it in the mixed solution, and ultrasonicate for 30min; weigh 1.6g Dissolve cetyltrimethylammonium bromide in the above dispersion, and stir at room temperature for 30 minutes; measure 400 μL of 0.2 M sodium hydroxide solution into the above solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com