Composite nitrogen cored wire for steelmaking as well as preparation and use methods thereof

A cored wire and alloy technology, applied in the field of composite nitrogen cored wire for steelmaking, can solve the problems of low vanadium utilization rate, alloy burning loss, high price, etc., to improve uniform distribution, reduce steelmaking cost, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

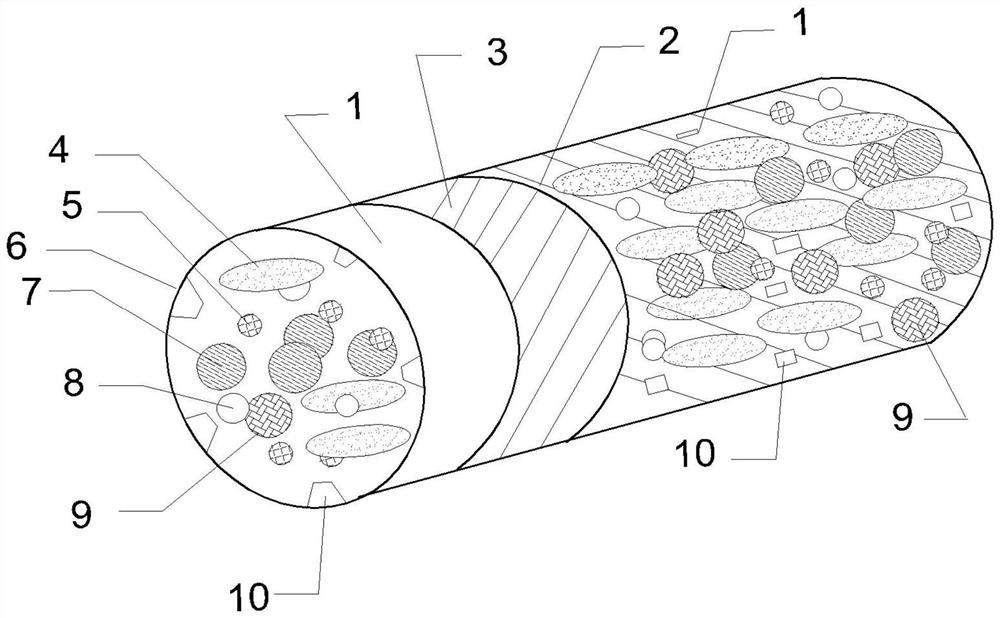

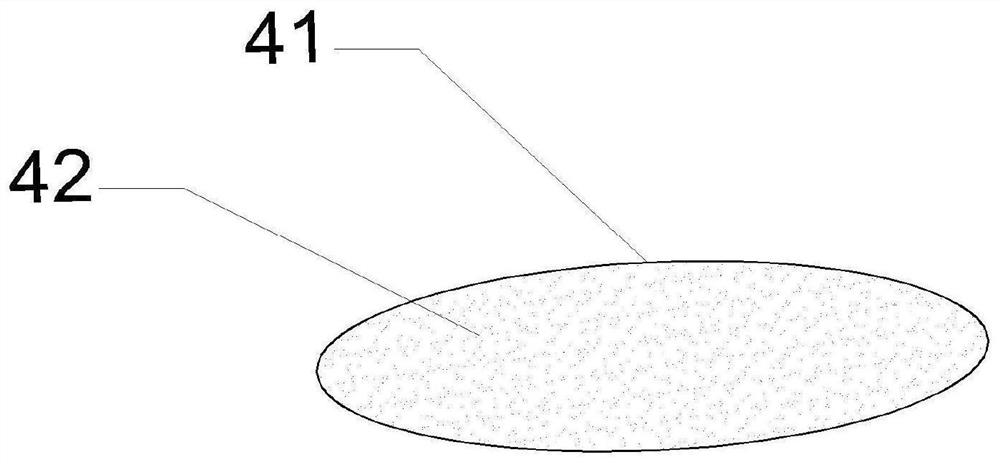

[0051] Such as figure 1 As shown, a composite nitrogen cored wire for steelmaking, including an alloy bin 1, a blind plate 2, a gas bin 3 and an iron shell 6, the outermost layer is an iron shell 6, and the inside of the iron shell 6 is provided with alloys The bin 1 and the gas bin 3, the alloy bin 1 and the gas bin 3 are separated by a blind plate 2, and the circumference of the blind plate 2 is connected with the inner wall of the iron shell 6, and the outermost iron shell 6 connects the alloy bin 1 and the blind plate along the circumferential direction. The plate 2 and the gas chamber 3 are wrapped and sealed; the inner core material is randomly distributed in the alloy chamber 1 sealed by the iron shell 6 and the blind plate 2, and the gas chamber 3 is filled with nitrogen.

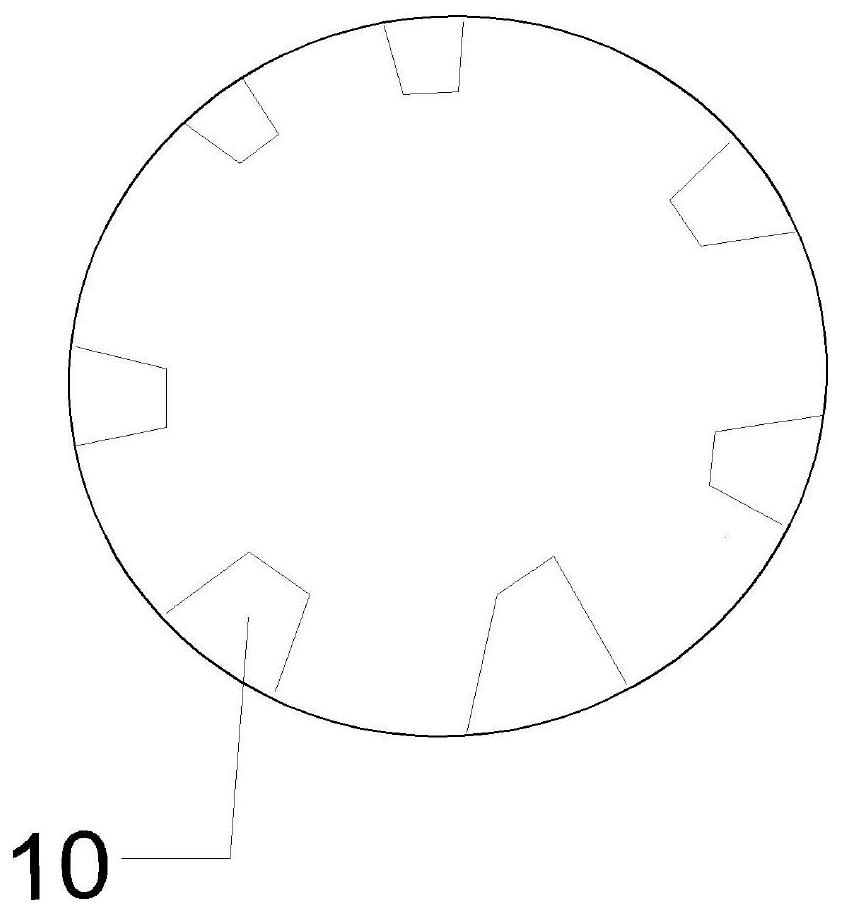

[0052] Such as figure 2As shown, the alloy bin 1 is provided with a material-resistance boss 10, one end of the material-resistance boss 10 is connected to the inner wall of the iron shell 6, and ...

Embodiment 2

[0091] Such as figure 1 As shown, a composite nitrogen cored wire for steelmaking, including an alloy bin 1, a blind plate 2, a gas bin 3 and an iron shell 6, the outermost layer is an iron shell 6, and the inside of the iron shell 6 is provided with alloys The bin 1 and the gas bin 3, the alloy bin 1 and the gas bin 3 are separated by a blind plate 2, and the circumference of the blind plate 2 is connected with the inner wall of the iron shell 6, and the outermost iron shell 6 connects the alloy bin 1 and the blind plate along the circumferential direction. The plate 2 and the gas chamber 3 are wrapped and sealed; the inner core material is randomly distributed in the alloy chamber 1 sealed by the iron shell 6 and the blind plate 2, and the gas chamber 3 is filled with nitrogen.

[0092] Such as figure 2 As shown, the alloy bin 1 is provided with a material-resistance boss 10, one end of the material-resistance boss 10 is connected to the inner wall of the iron shell 6, and...

Embodiment 3

[0109] Such as figure 1As shown, a composite nitrogen cored wire for steelmaking, including an alloy bin 1, a blind plate 2, a gas bin 3 and an iron shell 6, the outermost layer is an iron shell 6, and the inside of the iron shell 6 is provided with alloys The bin 1 and the gas bin 3, the alloy bin 1 and the gas bin 3 are separated by a blind plate 2, and the circumference of the blind plate 2 is connected with the inner wall of the iron shell 6, and the outermost iron shell 6 connects the alloy bin 1 and the blind plate along the circumferential direction. The plate 2 and the gas chamber 3 are wrapped and sealed; the inner core material is randomly distributed in the alloy chamber 1 sealed by the iron shell 6 and the blind plate 2, and the gas chamber 3 is filled with nitrogen.

[0110] Such as figure 2 As shown, the alloy bin 1 is provided with a material-resistance boss 10, one end of the material-resistance boss 10 is connected to the inner wall of the iron shell 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com