Method and device for optimizing surface residual stress of metal part based on electromagnetic induction heating and rapid surface cooling

An electromagnetic induction heating and rapid cooling technology, applied in the field of mechanical engineering, can solve the problems of inability to form stress, fatigue life and corrosion resistance of parts, limited optimization effect, etc., to prevent overheating oxidation, good optimization effect, and strong environmental protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for optimizing the surface residual stress of metal parts based on electromagnetic induction heating and rapid surface cooling, the optimization process includes the following steps:

[0039] S1. According to the specific materials of different metal parts and the optimization effect to be achieved, determine the final temperature and coolant of different electromagnetic induction heating;

[0040] S2. Put the part into the induction coil, and turn on the shielding gas before heating;

[0041] S3. Carry out stage-by-stage heating according to the set heating maximum temperature. After the inside and outside of the belt part reach the temperature of one stage evenly, then increase the power of the electromagnetic inductor to uniformly heat the part to the temperature of the next stage;

[0042] S4. Repeat the above steps to finally make the internal and external temperatures of the parts converge and reach the specified final temperature value;

[0043] S5, qui...

Embodiment 2

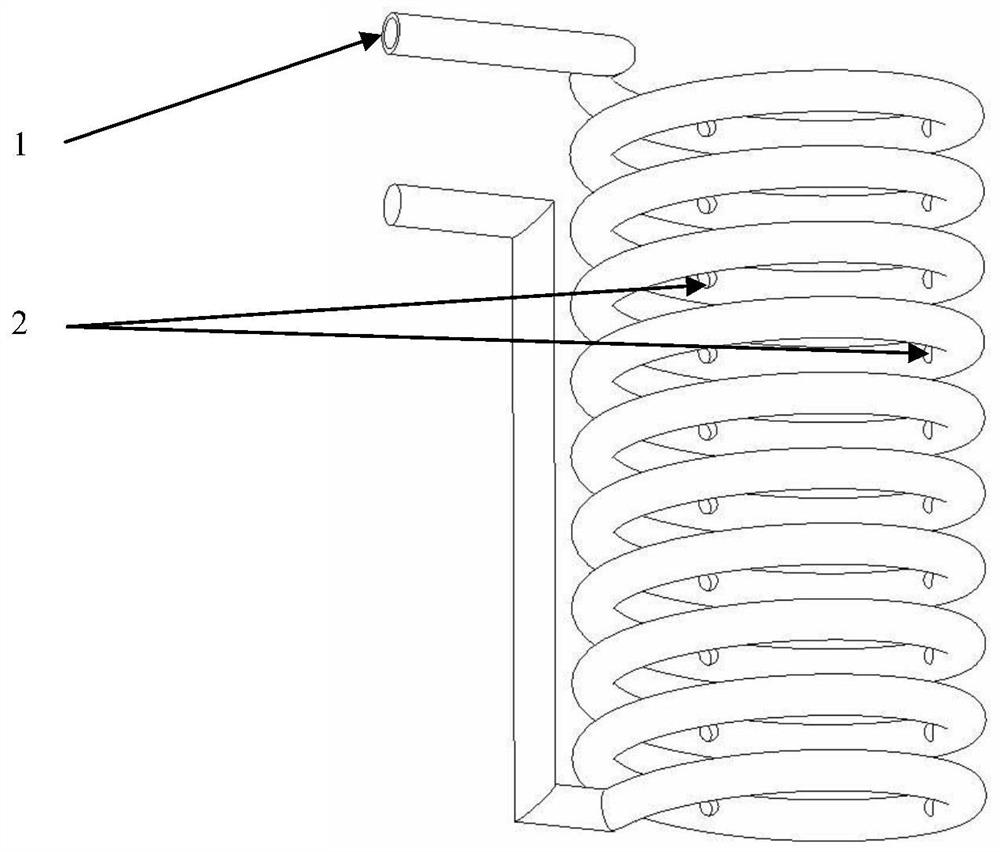

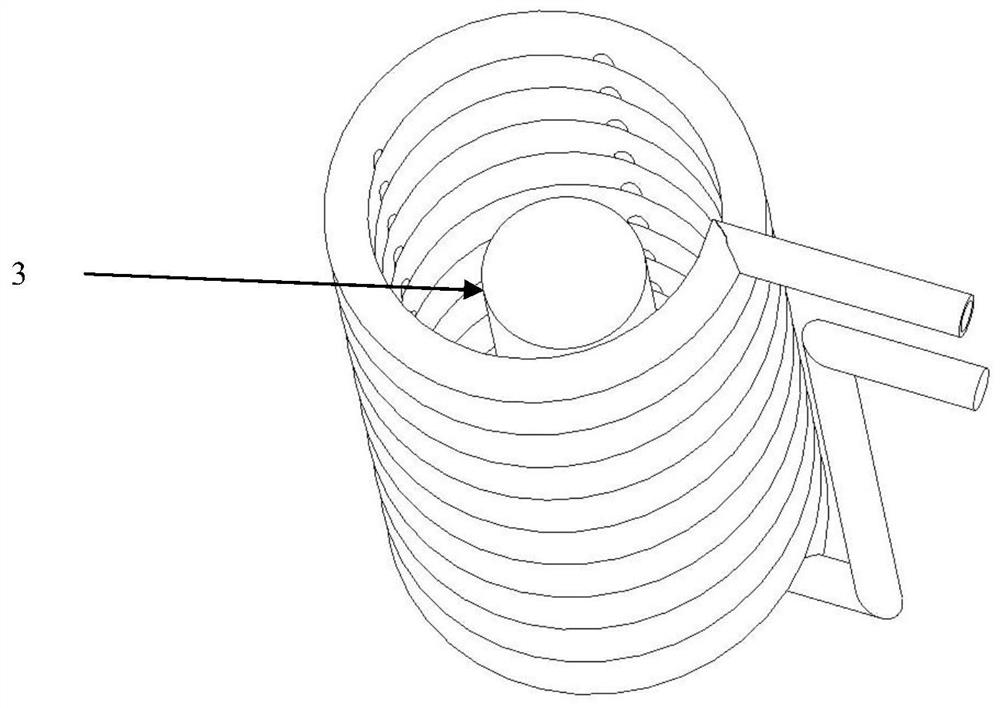

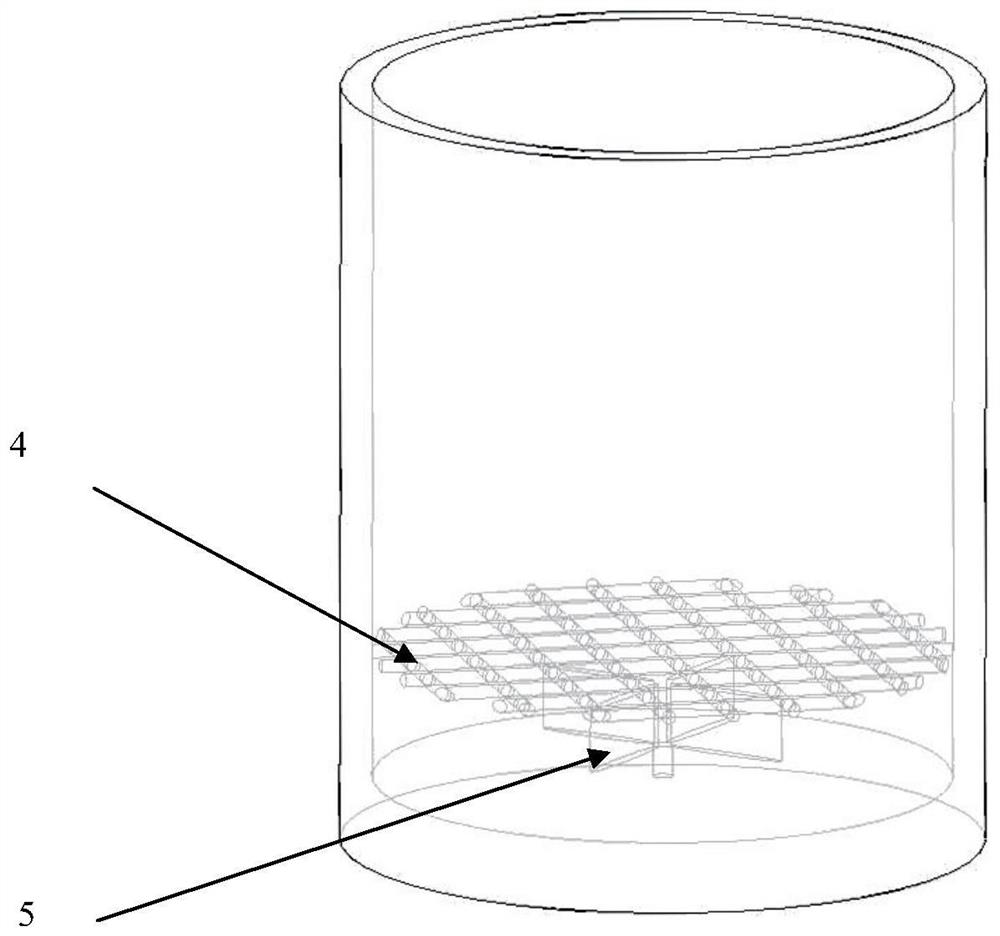

[0057] A device for optimizing the surface residual stress of metal parts based on electromagnetic induction heating and rapid surface cooling, including a spiral tube, a filter screen 4 in the container, and a stirring blade 5 in the container. One end of the spiral tube is a protective gas inlet 1, and the spiral tube A plurality of protective gas outlets 2 are arranged inside the tube, the spiral tube is placed in the filter screen 4 in the container, and the stirring blade 5 in the container is arranged below the filter screen 4 in the container.

[0058] Such as Figure 5 to Figure 10 , the surface was originally distributed with residual stress σ 0 After the component is uniformly heated, the entire component material expands uniformly. When the outer material is cooled rapidly, its volume will shrink rapidly, and a corresponding strain Δε will be generated at the same time. The hindering effect of the surface material produces tensile stress σ on the surface material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com