Stepless speed regulator based on differential transmission/power converging mechanism, and energy-saving system thereof

A technology of differential transmission and stepless speed regulation, which is applied in the direction of differential transmission, transmission, and mechanical energy control. The effect of permanent, easy and low-cost energy-saving retrofit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

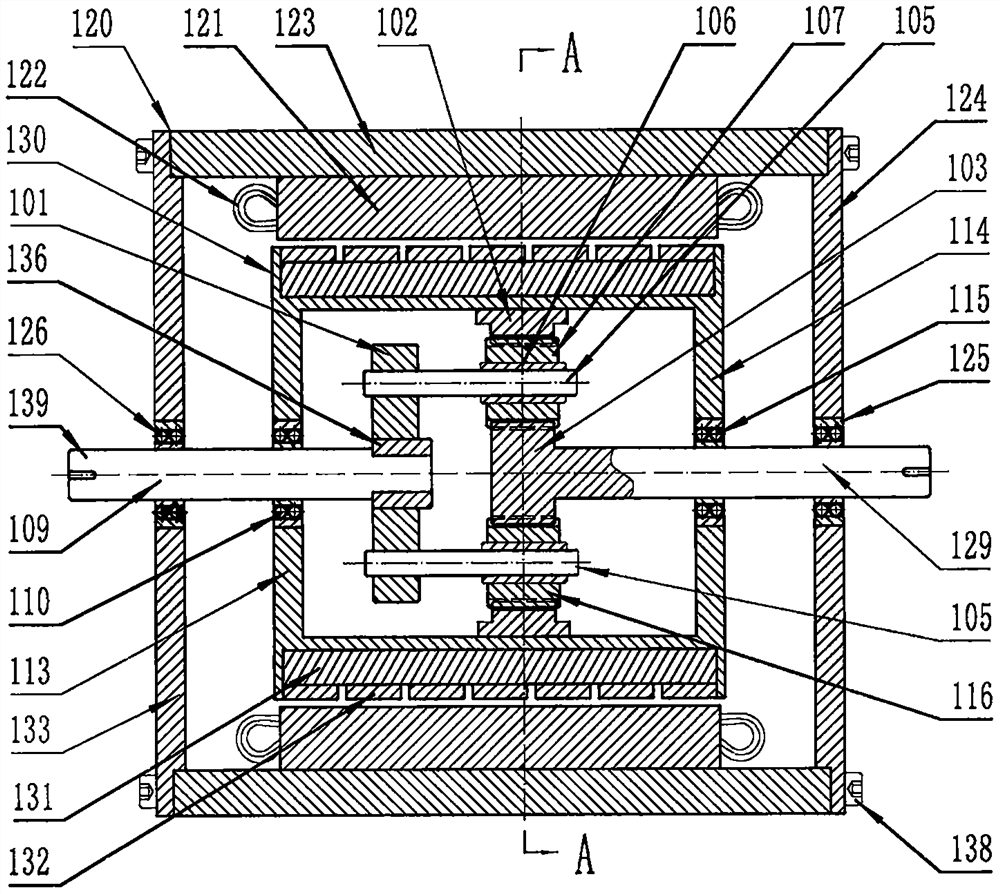

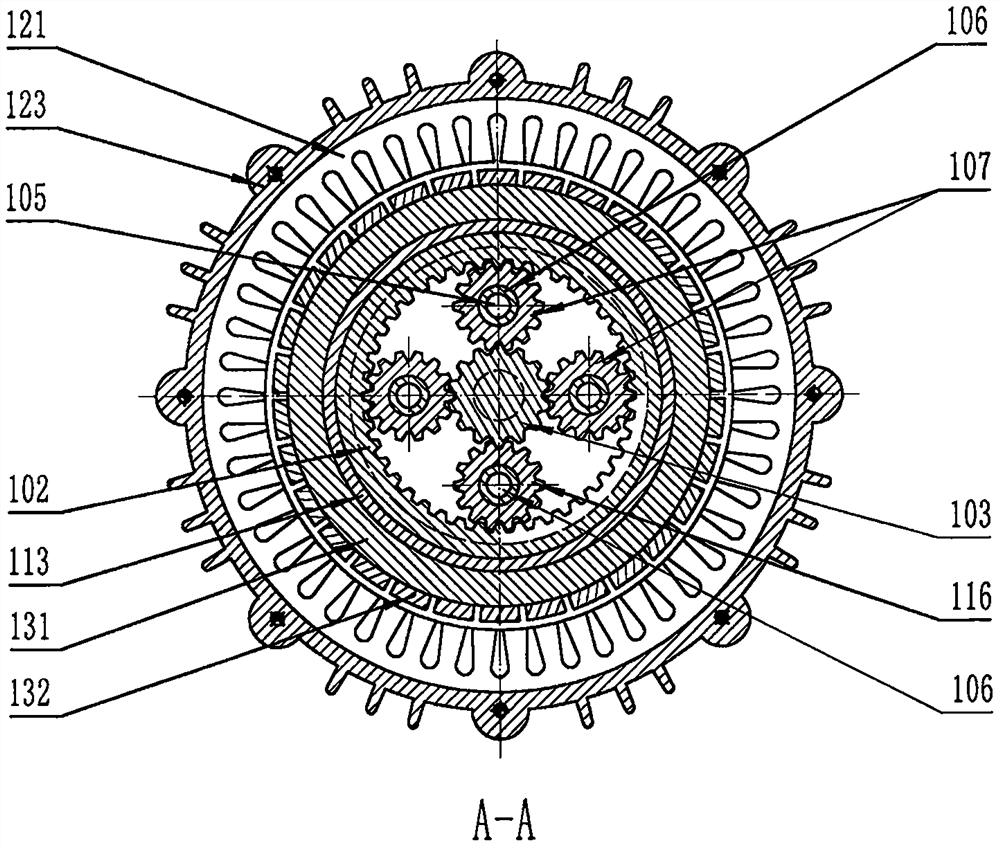

[0045] Such as figure 1 and figure 2As shown, it is a stepless speed governor based on a differential transmission / power confluence mechanism, and it is an embedded stepless speed governor based on an asymmetric axial cylindrical planetary gear differential transmission / power confluence mechanism. Asymmetric axial cylindrical planetary gear differential transmission / power converging mechanism (differential transmission / power converging mechanism is used in some common technical fields such as the automotive field, or is called differential, differential machine, in the field of transmission technology Or known as power splitter, power splitter, power converging mechanism, power splitting mechanism, etc., they have different or different structures in different application fields, but the working mechanism is similar) The components are embedded and set in the power regulation / speed regulation In the hollow rotor of the motor, it mainly consists of four axial cylindrical plan...

Embodiment 2

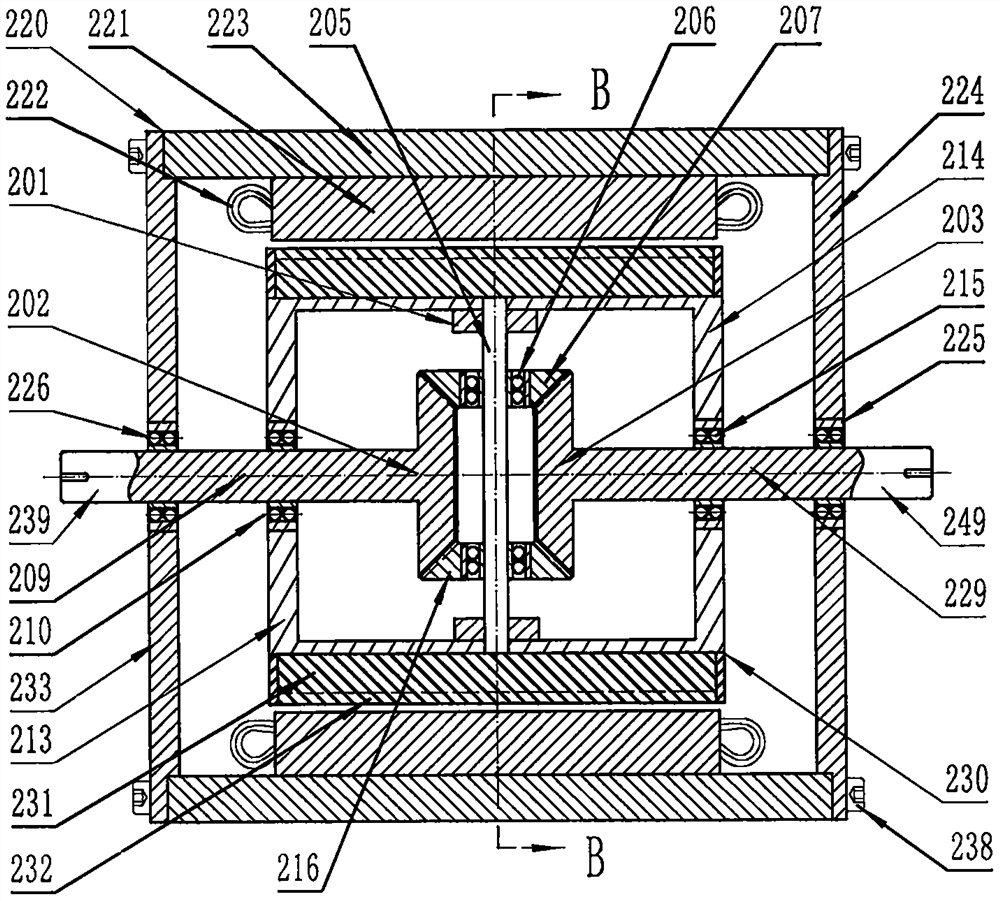

[0052] Such as image 3 and Figure 4 As shown, it is a stepless speed governor based on a differential transmission / power confluence mechanism, and it is an embedded stepless speed governor based on a symmetrical radial conical planetary gear differential transmission / power confluence mechanism. The differential transmission / power converging mechanism assembly is integrally embedded in the hollow rotor of the power adjustment / speed regulating motor, and it is mainly composed of radial conical planetary gears (207 and 216) differential transmission / power converging mechanism assembly (201, 202, 203 , 205, 206, 207, and 216), the stator (220, 221, 222, 223, 224, and 233) and the hollow rotor (230, 231, 232, 213, and 214) of the power regulation / speed regulating motor, based on the differential transmission Other accessories (226, 210, 215, 225 and 238) of the stepless speed governor of the power converging mechanism, a motor / generator duplex controller and a state sensor (not ...

Embodiment 3

[0057] Such as Figure 5 As shown, it is a stepless speed governor based on differential transmission / power confluence mechanism, which is an embedded stepless speed regulator based on asymmetrical axial double-ended circular planetary gear differential transmission / power confluence mechanism. accelerator. It is configured with a power regulation / speed regulation motor (320) to control a drive / frequency converter and a state sensor assembly (not shown), an asymmetrical axial double-ended circular planetary gear differential transmission / power converging machine assembly (301, 302 , 303, 305, 306, 307, 345, 356 and 316) are integrally embedded in the hollow rotor (330) of the squirrel-cage AC asynchronous power regulation / speed regulation motor (320), and the right half shaft (329) is the power output The end / shaft is set as the right half rotor shaft (329) of the hollow rotor shaft system (329) of the power regulation / speed regulation motor (320) through the correspondingly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com