A kind of nano magnesium oxide inorganic antibacterial agent and preparation method thereof

An inorganic antibacterial agent and nano-magnesium oxide technology, applied in the field of antibacterial materials, can solve the problems of limited application field and low antibacterial activity of nano-magnesium oxide inorganic antibacterial agent, and achieve the effects of improving antibacterial performance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

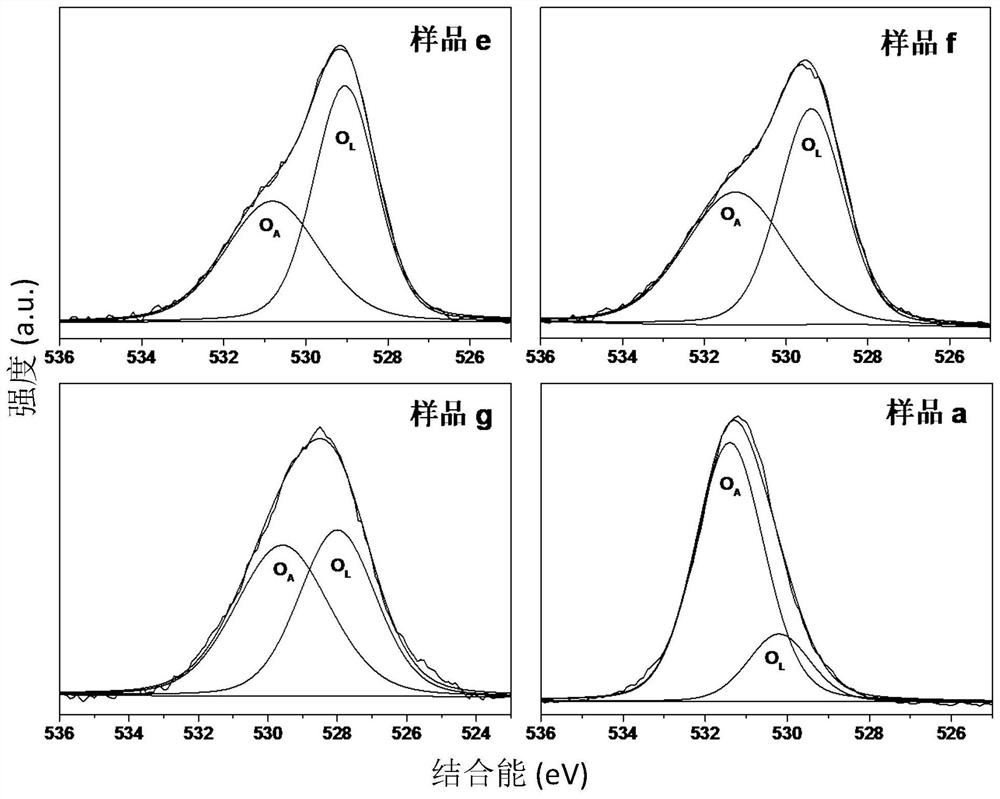

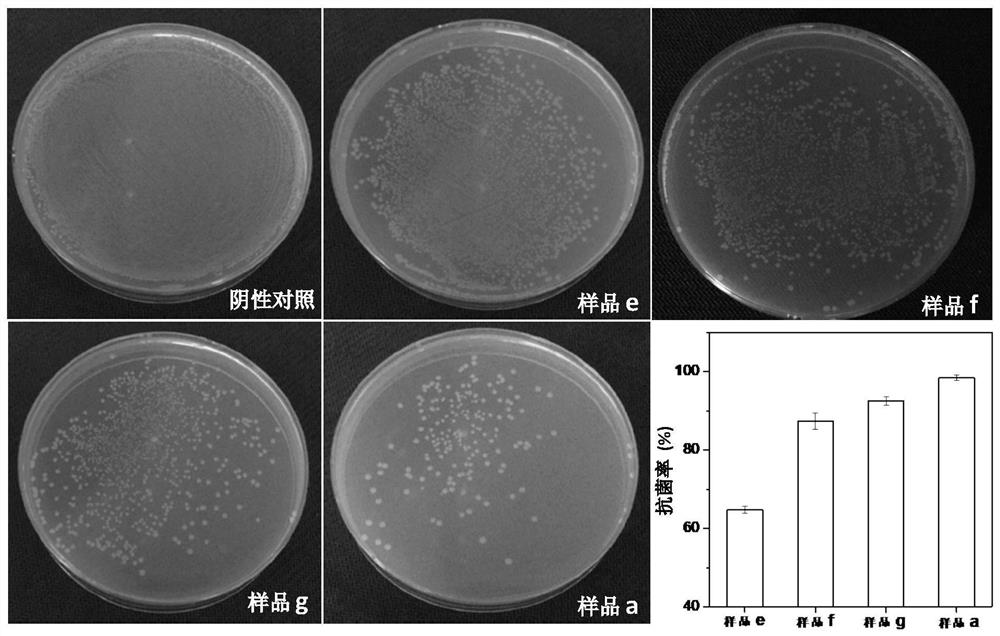

Embodiment 1

[0028] 9.25mmol of MgCl 2 ·6H 2 O, 0.75mmol of LiNO 3 (the molar proportion is 7.5%) and 0.3mmol of EDTA-2Na were dissolved in 70mL of deionized water, and a clear solution was obtained after stirring; 10mL of NH 3 ·H 2 O was added dropwise to the above clear liquid and stirred vigorously for 20 min, put into the reaction kettle and heated at 180°C for 24 h, and cooled to room temperature after taking it out. After centrifuging the solution and precipitate in the reaction kettle to remove the supernatant, washing and centrifuging with deionized water and absolute ethanol respectively, vacuum-drying the white precipitate to obtain a precursor. Finally, the precursor was calcined at 750 °C for 4 h in nitrogen, and the prepared antibacterial agent was denoted as a. Antibacterial agent a with a concentration of 100 μg / mL can efficiently inactivate 10 8 Escherichia coli with cfu / mL has an antibacterial rate of 98.5%. Antibacterial agent a with a concentration of 450 μg / mL can...

Embodiment 2

[0030] 9.50mmol of MgCl 2 ·6H 2 O, 0.5mmol LiNO 3 (5.0% by molar ratio) and 0.3mmol of EDTA-2Na were dissolved in 70mL of deionized water, and after stirring, a clear solution was obtained; 10mL of NH 3 ·H 2 O was added dropwise to the above clear liquid and stirred vigorously for 20 min, put into the reaction kettle and heated at 180°C for 24 h, and cooled to room temperature after taking it out. After centrifuging the solution and precipitate in the reaction kettle to remove the supernatant, washing and centrifuging with deionized water and absolute ethanol respectively, vacuum-drying the white precipitate to obtain a precursor. Finally, the precursor was calcined at 750 °C for 4 h in nitrogen, and the prepared antibacterial agent was denoted as b. Antibacterial agent b at a concentration of 100 μg / mL can efficiently inactivate 10 8 Escherichia coli with cfu / mL has an antibacterial rate of 92.5%.

Embodiment 3

[0032] 9.25mmol of MgCl 2 ·6H 2 O, 0.75mmol of LiNO 3 (the molar proportion is 7.5%) and 0.3mmol of EDTA-2Na were dissolved in 70mL of deionized water, and a clear solution was obtained after stirring; 10mL of NH 3 ·H 2 O was added dropwise to the above clear liquid and stirred vigorously for 20 min, put into the reaction kettle and heated at 180°C for 24 h, and cooled to room temperature after taking it out. After centrifuging the solution and precipitate in the reaction kettle to remove the supernatant, washing and centrifuging with deionized water and absolute ethanol respectively, vacuum-drying the white precipitate to obtain a precursor. Finally, the precursor was calcined at 650 °C for 4 h in nitrogen, and the prepared antibacterial agent was denoted as c. Antibacterial agent c at a concentration of 100 μg / mL can efficiently inactivate 10 8Escherichia coli with cfu / mL has an antibacterial rate of 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com