Novel film-coated plugging disc

A blocking disk and film-covering technology, which is applied in the field of medical devices, can solve the problems that the blocking disk and flow-blocking film cannot be completely covered, the thickness of the film cannot be too thick, and the sealing is not complete, so as to achieve controllability and Fully repeatable recyclability, avoiding direct contact, and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

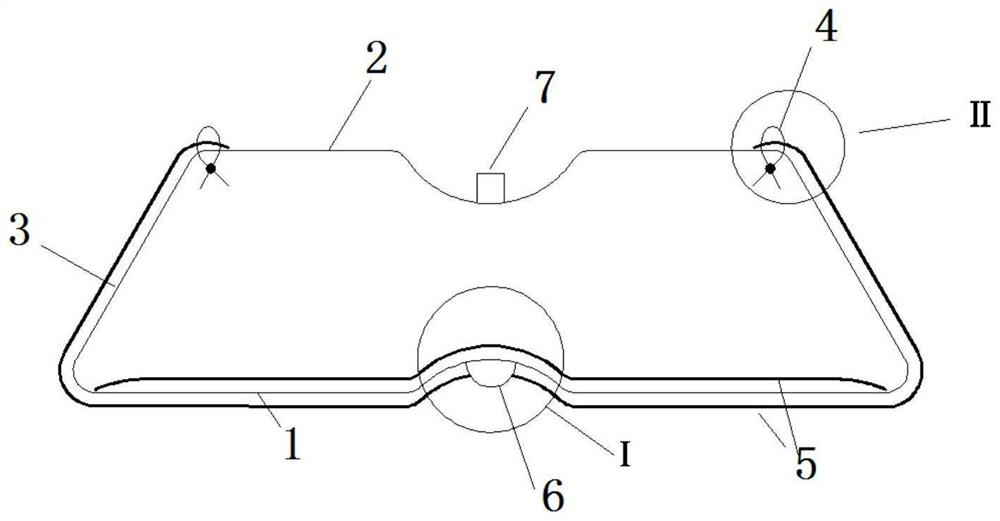

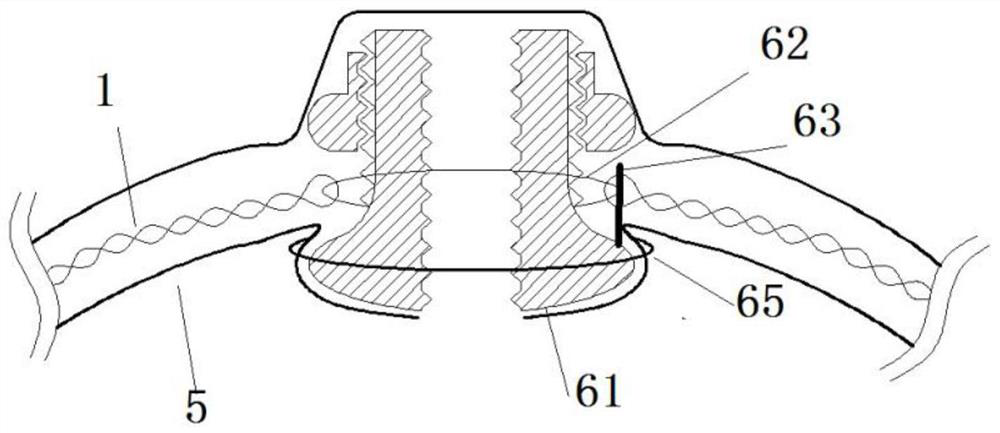

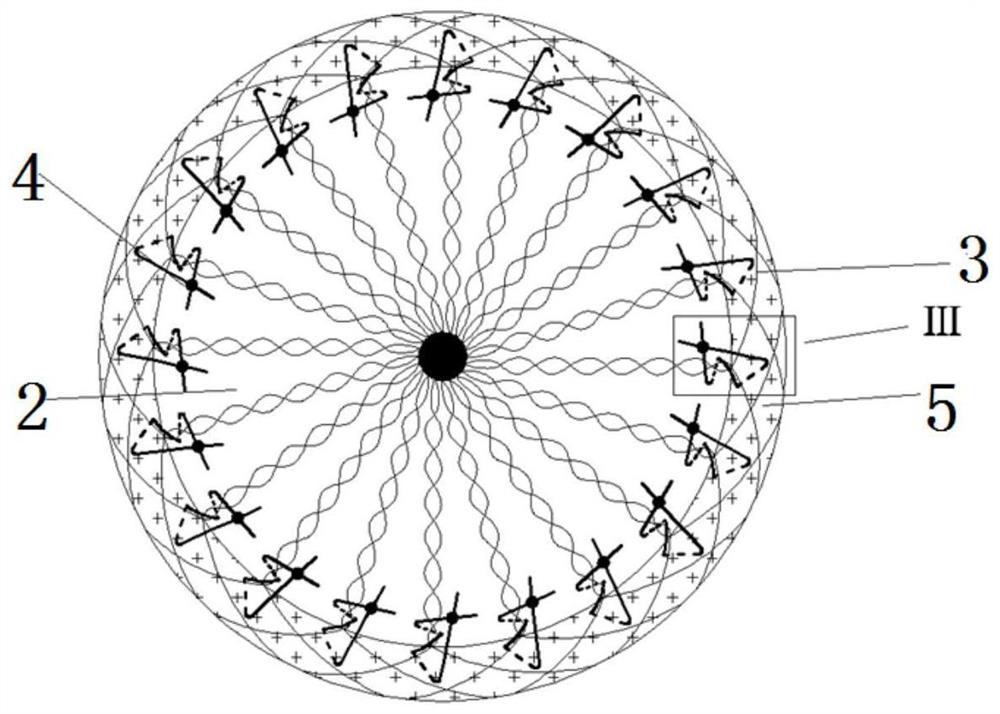

[0086] Such as Figure 1-3 As shown, this embodiment provides a new membrane-coated occlusion disc, which includes a plurality of elastic and / or shape-memory support rods, a first choke film, and a first deformation compensation structure 4; wherein, a plurality of support rods From the first central part 6, the first support expansion surface 1, the waist support expansion surface 3 and the second support expansion surface 2 are sequentially extended, and they are gathered at the second central part 7 to form a cage-like structure; Coating film 5, coating film 5 is wrapped on the outer surface of the first central part 6, the inner and outer surfaces of the first support unfolding surface 1 and the outer surface of waist support unfolding surface 3, the far-end edge of coating film 5 and the second The support deployment surface 2 is connected by a first deformation compensation structure 4 .

[0087] In the prior art, the flow-blocking membrane on the occlusion disk is plug...

Embodiment 2

[0093] Such as Figure 10-12 Among them, compared with embodiment 1, the first difference between embodiment 2 and embodiment 1 is that: the first choke membrane also includes a reinforced blocking body 9, which is arranged on the second support expansion surface of the blocking disk 2, the edge of the reinforced blocking body 9 is connected with the edge of the coating film 5 and the lumbar support unfolding surface 3 through the first deformation compensation structure 4, so that in the natural state, the coating film 5 and the reinforced blocking body 9 form a The closed cage shape adapted to the shape of the occlusion disk, the reinforced occlusion body 9 is made of a flexible film, and the flexible film has a microporous structure 51, which is convenient for liquid to enter and exit. In addition, the microporous structure 51 is more conducive to tissue growth, so the reinforced occlusion body 9 provided by the occlusion disk is also conducive to accelerating the endotheli...

Embodiment 3

[0101] refer to Figure 14 , 15 , The first difference between embodiment 3 and embodiment 1 is: the coating film 5 not only covers the lumbar support deployment surface 3 but also covers the second support deployment surface 2, and the coating film at the second support deployment surface 2 5 is provided with a microporous structure 51, so that liquid can come in and go out, which is convenient for emptying before operation.

[0102] The second difference is that: if Figure 15 Among them, the first deformation compensation structure 4 is located at the edge of the coating film 5, and the first deformation compensation structure 4 is a series line on a plurality of independent support rods surrounding the second support development surface 2, and the series line passes through or A plurality of independent support rods and a covering film 5 on the second support deployment surface 2 are wound, so that the series lines are connected end to end. The advantage of this design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com