Loratadine oral dispersible film agent and preparation method thereof

A loratadine and dispersing film technology, which is applied in the field of medicine and its preparation, can solve the problems of poor tensile strength, disintegration speed, taste, and stability of the oral instant film of loratadine, and achieves easy dosage control, Safe storage, easy to take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

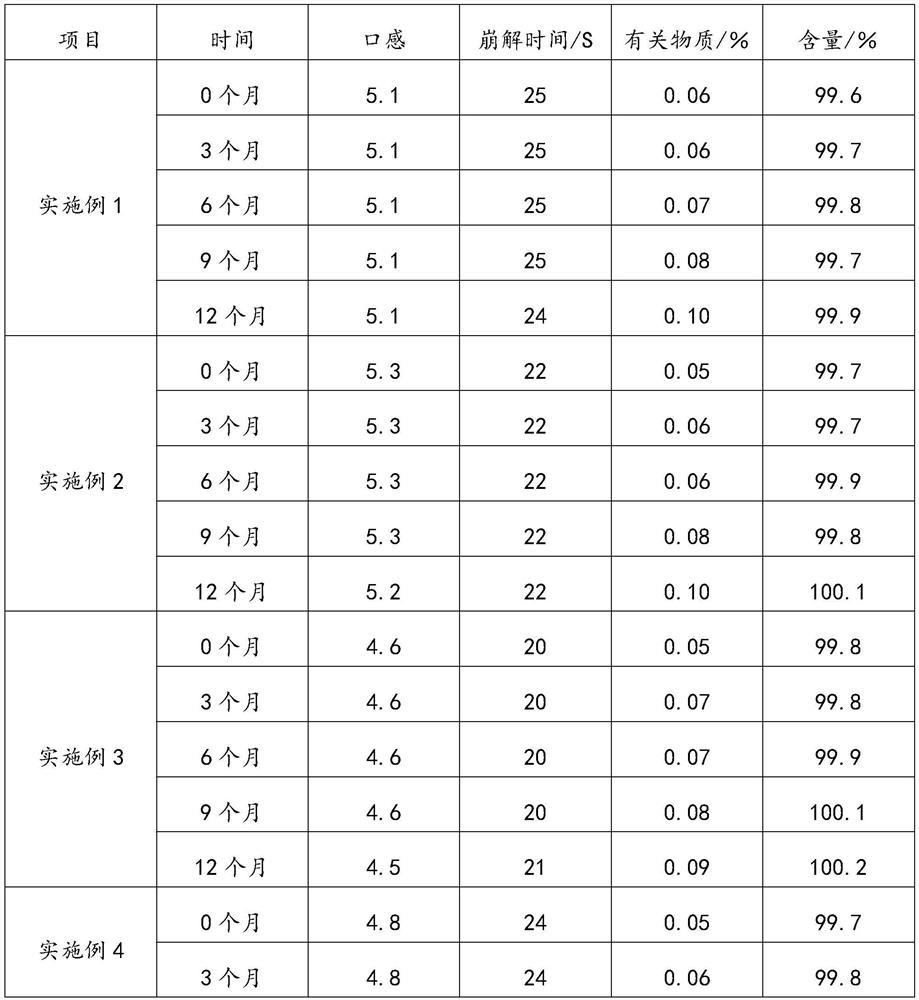

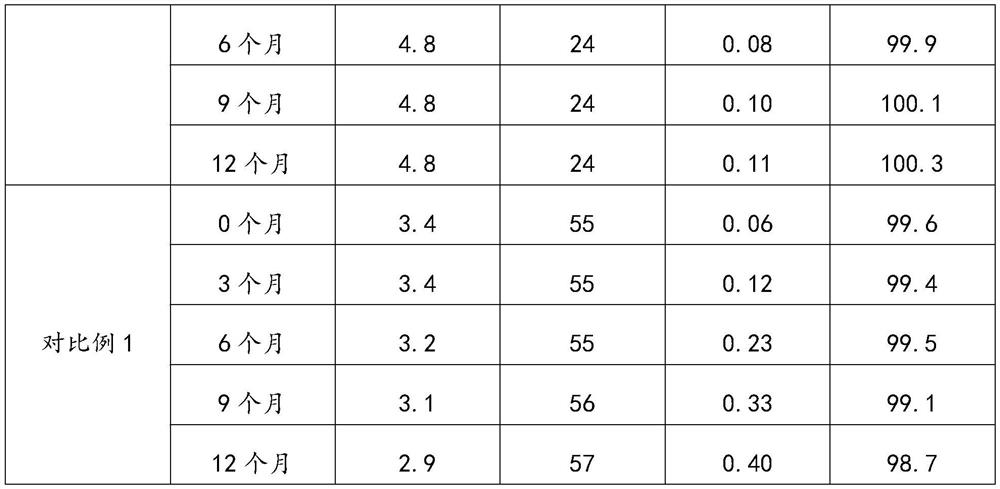

Examples

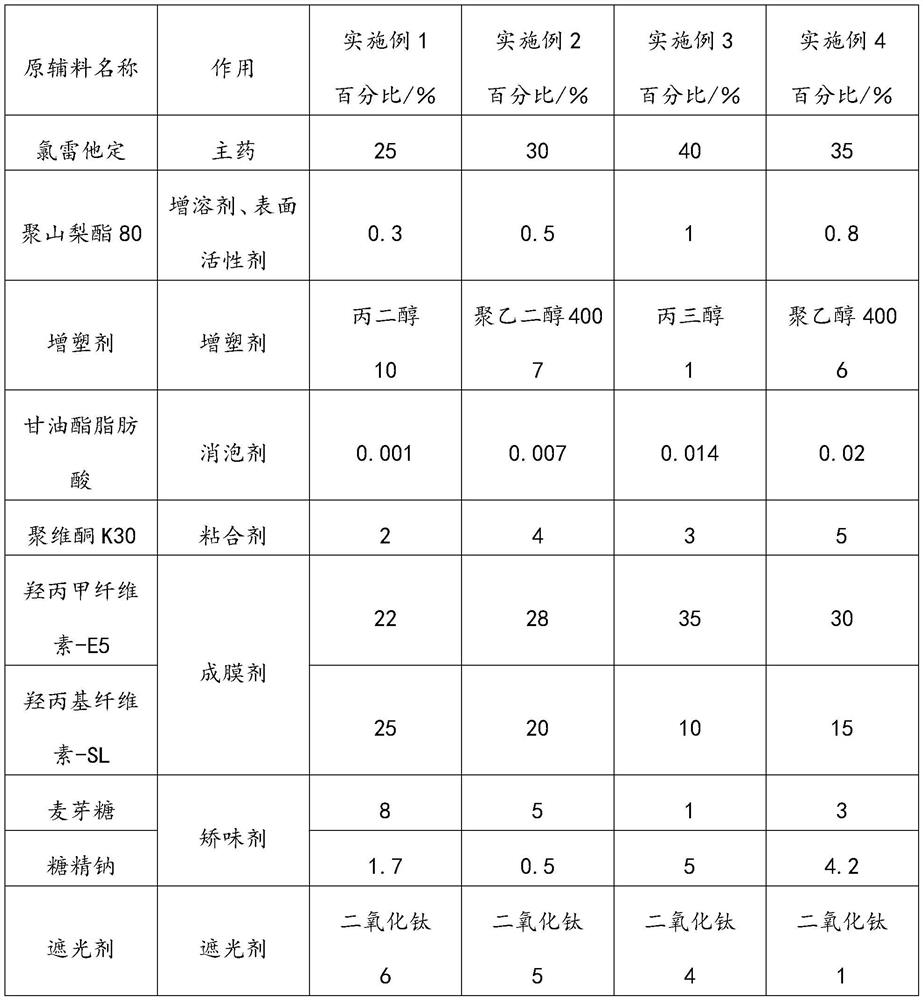

preparation example Construction

[0044] The preparation method of loratadine oral dispersible film, comprises the following steps:

[0045] 1) Add polysorbate 80, plasticizer and glyceride fatty acid into purified water at 80°C under stirring, and stir evenly;

[0046] 2) Add povidone K30, hypromellose-E5 and hydroxypropyl cellulose-SL into the dispersion system obtained in step 1) under stirring, stir evenly, and cool the solution temperature to room temperature;

[0047] 3) Adding a prescribed amount of ethanol to the solution obtained in step 2) and mixing evenly, adding loratadine with a particle size of X90≤10 μm, and stirring evenly to obtain a film solution;

[0048] 4) Add maltose, sodium saccharin and opacifying agent to the film solution obtained in step 3), stir evenly, then perform homogenization, defoaming, coating, drying and cutting in sequence to obtain the orodispersible loratadine film agent.

[0049] Further, in step (1) and step (2), the stirring speed is 2000-3000r / min. In step (4), th...

Embodiment 1

[0055] The preparation method of loratadine oral dispersible film, comprises the following steps:

[0056] 1) Add polysorbate 80, propylene glycol and glyceride fatty acid into purified water at 80°C under stirring, and stir evenly; wherein, the stirring speed is 2000r / min;

[0057] 2) Add povidone K30, hypromellose-E5 and hydroxypropyl cellulose-SL to the dispersion system obtained in step 1) under stirring, stir evenly, and cool the solution temperature to room temperature; , the stirring speed is 3000r / min;

[0058] 3) Add the prescribed amount of ethanol to the solution obtained in step 2) and mix evenly, then add loratadine with a particle size of X90=1 μm, and stir evenly to obtain a film solution;

[0059] 4) Add maltose, sodium saccharin and titanium dioxide to the film solution obtained in step 3), stir evenly, and then perform homogenization, defoaming, coating, drying and cutting in sequence to obtain the orodispersible film of loratadine agent; wherein, the numbe...

Embodiment 2

[0061] The preparation method of loratadine oral dispersible film, comprises the following steps:

[0062] 1) Add polysorbate 80, polyethylene glycol 400 and glyceride fatty acid into purified water at 80°C under stirring, and stir evenly; wherein, the stirring speed is 2300r / min;

[0063] 2) Add povidone K30, hypromellose-E5 and hydroxypropyl cellulose-SL to the dispersion system obtained in step 1) under stirring, stir evenly, and cool the solution temperature to room temperature; , the stirring speed is 2700r / min;

[0064] 3) Add the prescribed amount of ethanol to the solution obtained in step 2) and mix evenly, then add loratadine with a particle size of X90=4 μm, and stir evenly to obtain a film solution;

[0065] 4) Add maltose, sodium saccharin and titanium dioxide to the film solution obtained in step 3), stir evenly, and then perform homogenization, defoaming, coating, drying and cutting in sequence to obtain the orodispersible film of loratadine agent; wherein, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com