Application of special amino acid derivative in preparing preparation for preventing and controlling African swine fever

A technology of derivatives and amino acids, applied in the direction of antiviral agents, drug combinations, medical preparations with non-active ingredients, etc., can solve the problems of no effective vaccine for preventing African swine fever, change of owner risk pig farms, impacts, etc., to achieve Effects of preventing digestion and absorption, prolonging shelf life, and reducing feeding frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

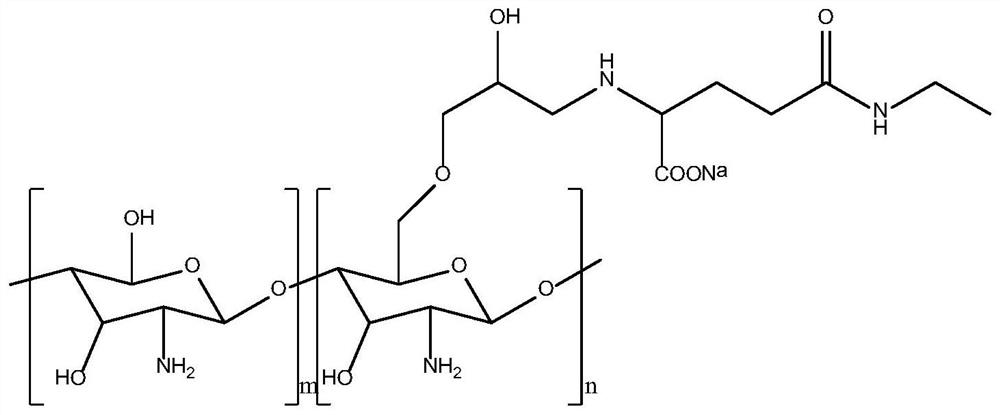

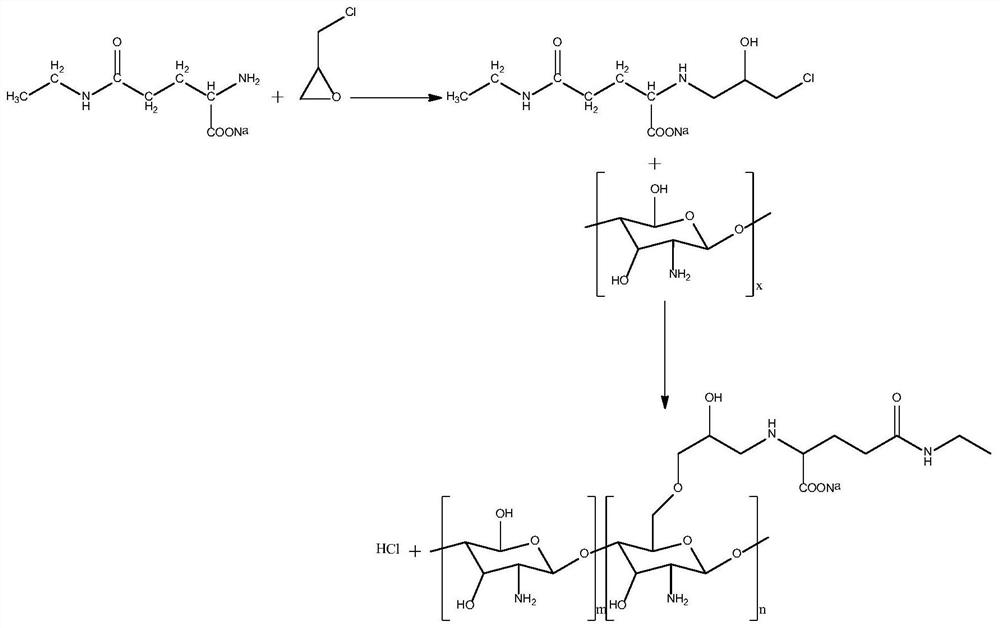

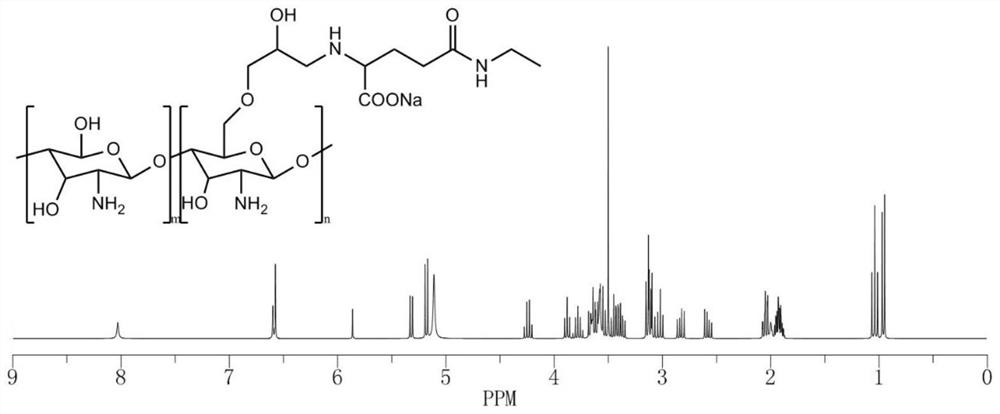

[0052] The preparation process of chitosan theanine derivatives described in the present application is shown in the following formula (2).

[0053]

[0054] The specific steps of the process for preparing chitosan theanine derivatives include:

[0055] 1) Dissolve theanine in a sufficient amount of distilled water, adjust the pH of the solution to 9-10, stir and reflux at a temperature of 45-50°C, slowly add epichlorohydrin which is equimolar to theanine, and react until the solution is completely clear Dehydration and recrystallization with acetone, washing with absolute ethanol at least 5 times, and drying to obtain theanine epichlorohydrin intermediate;

[0056] 2) Add chitosan with a high degree of deacetylation that is dried to constant weight into 10-15 times by weight of isopropanol, stir and make it fully swell for at least 4 hours, and then add 15-30 times the weight of chitosan for hydrogen oxidation Sodium solution, mix well and place at 5-10°C for at least 48 ...

Embodiment 1

[0072] The present embodiment provides a chitosan theanine derivative:

[0073] 1) Dissolve 1.72g (0.01mol) theanine in 50g distilled water, adjust the pH to 10 with 20% sodium hydroxide solution, stir and reflux at 300r / min at 50°C, slowly add 0.01mol dropwise at a rate of 10mL / min Epichlorohydrin, reacted until the solution was completely clear, dehydrated and recrystallized with acetone, washed 5 times with absolute ethanol, and dried in vacuum at 50°C to constant weight to obtain 2.48g of theanine epichlorohydrin intermediate, with a yield of 86.1 %;

[0074] 2) Add 413.3g of chitosan (deacetylation degree 100%, weight average molecular weight 100000) dried to constant weight into 4200g of isopropanol, stir at 600r / min and make it fully swell for 4h, then add 8300g of 15% chitosan Sodium hydroxide solution, mix well and place at 10°C for 48 hours;

[0075] 3) ultrafiltration step 2) the fully swollen chitosan, filter out the sodium hydroxide, dissolve in a large amount o...

Embodiment 2

[0077] The present embodiment provides a chitosan theanine derivative:

[0078] 1) with embodiment 1;

[0079] 2) Add 620g of chitosan (deacetylation degree 100%, weight average molecular weight 100000) dried to constant weight into 6500g of isopropanol, stir at 600r / min and make it fully swell for 4h, then add 9300g of 15% hydrogen Sodium oxide solution, mixed evenly and placed at 10°C for 48 hours;

[0080] 3) Obtain chitosan theanine derivatives with Example 1, that is, the weight ratio of chitosan and theanine epichlorohydrin intermediate is 100:0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com