Chelating type blocking remover and preparation method and application thereof

A plug-removing agent, chelating-type technology, applied in the field of chelating-type plugging-removing agent and its preparation, can solve the problems of increased discharge treatment requirements, difficult post-treatment of residual acid, unobvious plug-removing effect, etc., to achieve non-corrosion equipment, improve long-term sustainability, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

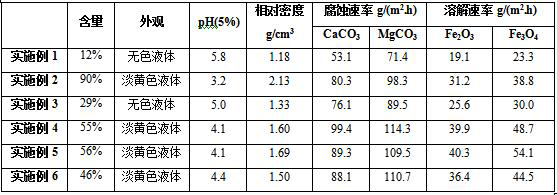

Embodiment 1

[0043]The preparation method of the chelating type plugging agent in Example 1 is as follows: add 880 grams of water to the reaction kettle, heat it to 50°C, first weigh 10 grams of the dispersant polyacrylamide into the water, and stir it with a high-speed homogenizer for 1 After stirring evenly, add 50 grams of tetrasodium iminodisuccinate and 0 grams of tetrasodium edetate into the reaction kettle, and then continue to stir evenly. After the system is evenly dispersed, add two 50 grams of -1,6-hexamethylenetriamine pentamethylene phosphonic acid and 0 grams of polyaspartic acid were added to the reaction kettle, and the stirring was continued, and finally 10 grams of active synergist polyquaternium-37 was added, Continue high-speed stirring for 2 hours, stop stirring, cool down naturally, and age for 24 hours, the preparation is complete. The active substance content is 12%.

Embodiment 2

[0045] The preparation method of the chelating type plugging agent in Example 2 is as follows: add 100 grams of water to the reaction kettle, heat it to 50°C, first weigh 50 grams of the dispersant polyacrylamide and add it to the water, and stir it with a high-speed homogenizer for 1 Add 250 grams of chelating agent tetrasodium iminodisuccinate and 50 grams of chelating agent tetrasodium edetate into the reaction kettle after stirring evenly, and then continue to stir evenly. After the system is uniformly dispersed, add scale inhibitor double Add 300 grams of -1,6-hexamethylenetriamine pentamethylene phosphonic acid and 200 grams of polyaspartic acid into the reaction kettle, continue to stir evenly, and finally add 50 grams of active synergist polyquaternium-37, Continue high-speed stirring for 2 hours, stop stirring, cool down naturally, and age for 24 hours, the preparation is complete. The active substance content is 90%.

Embodiment 3

[0047] The preparation method of the chelating type plugging agent in Example 3 is as follows: add 710 grams of water to the reaction kettle, heat it to 50°C, first weigh 10 grams of the dispersant polyacrylamide into the water, and stir it with a high-speed homogenizer for 1 Add 100 grams of chelating agent tetrasodium iminodisuccinate and 20 grams of chelating agent tetrasodium ethylenediamine tetraacetate into the reaction kettle after stirring evenly, and then continue to stir evenly. 100 grams of -1,6-hexamethylene triamine pentamethylene phosphonic acid and 50 grams of polyaspartic acid were added to the reaction kettle, and the stirring was continued. Finally, 10 grams of active synergist polyquaternium-37 was added, Continue high-speed stirring for 2 hours, stop stirring, cool down naturally, and age for 24 hours, the preparation is complete. The active substance content is 29%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com