Neutral tin additive and preparation method and application thereof

A tin additive and neutral technology, applied in the field of neutral tin additive and its preparation, can solve the problems of large pollution and strong acidity of the plating solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

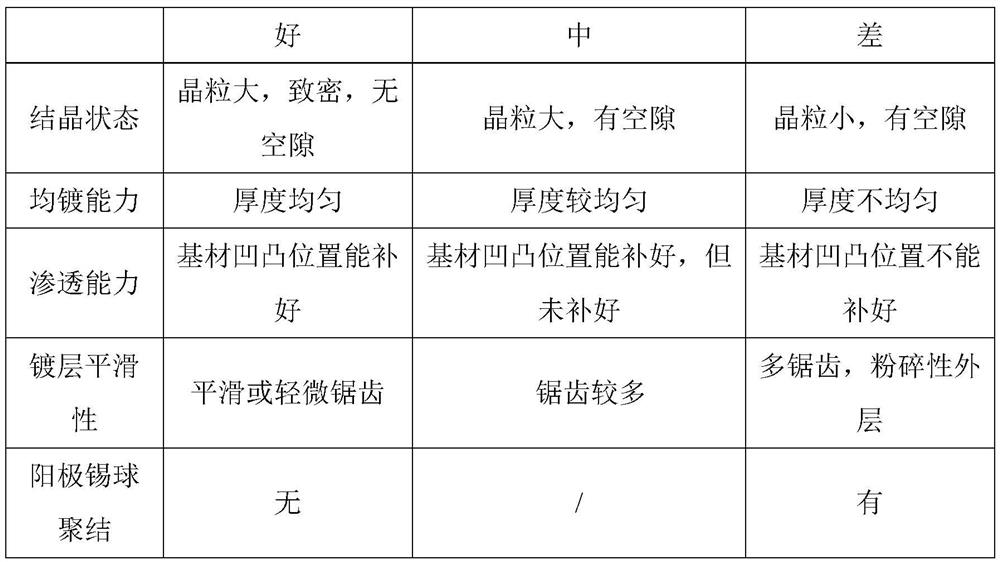

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The second aspect of the present invention provides the preparation method of the neutral tin additive, comprising the following steps: adding a buffering agent into water, mixing evenly, adding a wetting agent and a dispersant, and continuing to mix evenly; then adding a complexing agent, stirring Uniform; finally add pH regulator, stir evenly, that is.

[0064] The third aspect of the present invention provides the application of the neutral tin additive in the field of electroplating.

[0065] The fourth aspect of the present invention provides a kind of tin plating liquid, and its preparation raw material comprises: tin methanesulfonate 200-500g / L, above-mentioned neutral tin additive, solvent is water; Described tin methanesulfonate and neutral tin The volume ratio of the tin additive is 1:(5-15).

[0066] The fifth aspect of the present invention provides a method for preparing the above-mentioned tin plating solution, comprising the following steps: adding neutr...

Embodiment 1

[0071] Embodiment 1 provides a kind of neutral tin additive, comprises the following components by weight percentage: wetting agent 0.06%, dispersant 0.10%, complexing agent 28.0%, pH adjusting agent 12.2%, buffering agent 2.6%, water Make up the balance.

[0072] The wetting agent is dodecyl dimethyl benzyl ammonium chloride; the dispersant is zwitterionic n-propionate sodium salt, purchased from Shenzhen Xinaoyuan Technology Co., Ltd.; the complexing agent is methyl The combination of sulfonic acid and sodium gluconate has a weight ratio of 1:1; the pH regulator is sodium hydroxide; and the buffer is boric acid.

[0073] The preparation method of the neutral tin additive comprises the following steps: adding a buffering agent into water, mixing evenly, adding a wetting agent and a dispersant, and continuing to mix evenly; then adding a complexing agent, stirring evenly; finally adding a pH regulator, stirring Evenly, that is.

Embodiment 2

[0075] Embodiment 2 provides a kind of neutral tin additive, comprises the following components by weight percentage: wetting agent 0.01%, dispersant 0.02%, complexing agent 20%, pH adjusting agent 10%, buffering agent 1%, water Make up the balance.

[0076] The wetting agent is dodecyl dimethyl benzyl ammonium chloride; the dispersant is zwitterionic n-propionate sodium salt, purchased from Shenzhen Xinaoyuan Technology Co., Ltd.; the complexing agent is methyl The combination of sulfonic acid and sodium gluconate has a weight ratio of 1:1; the pH regulator is sodium hydroxide; and the buffer is boric acid.

[0077] The preparation method of the neutral tin additive comprises the following steps: adding a buffering agent into water, mixing evenly, adding a wetting agent and a dispersant, and continuing to mix evenly; then adding a complexing agent, stirring evenly; finally adding a pH regulator, stirring Evenly, that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com