Cellulose stripping and functionalization method thereof

A functionalized and cellulose technology, applied in the field of biomass resource utilization and transformation, can solve the problems of complex process method and huge water treatment cost, and achieve the effects of simple preparation steps, short ultrasonic peeling time and extremely high consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

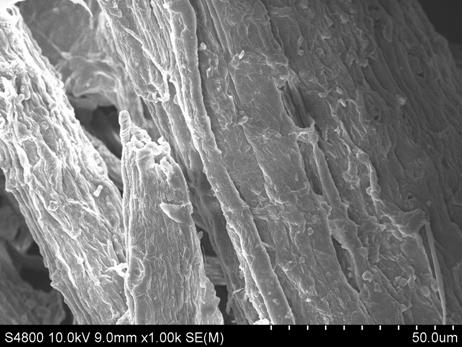

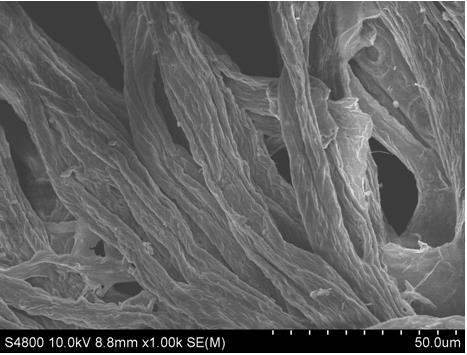

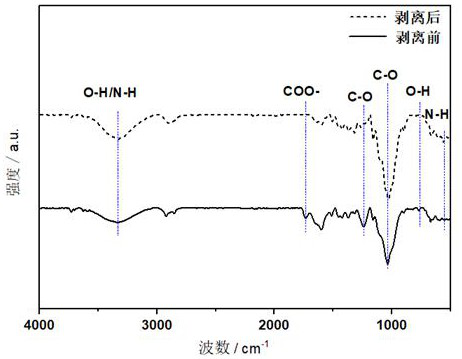

Embodiment 1

[0024] In the mixed solvent of triethanolamine and tetramethylpiperidine nitrogen oxide with a volume ratio of 1:1, add a mixture of disodium edetate and 200-mesh sieved betel nut residue with a mass ratio of 2:1, mix The mass ratio of solvent to mixture is 2:1, and the initial concentration of betel nut residue is 30 mg mL -1 , 40KHz, 480W ultrasonic stripping for 2 hours, 5000 rpm, 45 min centrifugation, remove the unpeeled betel nut residue, collect the suspension to obtain the functionalized cellulose dispersion. A linear fiber with a diameter of about 5-10 μm ( figure 1 ), at 3333 cm -1 Occurrence of hydroxyl and functionalized amine groups at 1239 cm -1 The C-O vibration of hemicellulose weakens at 1036 cm -1 C-O vibration enhancement of cellulose at image 3 ), indicating that high-purity functionalized cellulose was obtained from betel nut residue.

Embodiment 2

[0026] In the mixed solvent of phosphoric acid and tetramethylpiperidine nitrogen oxide in a volume ratio of 1:1, add the mixture of sodium tartrate and 200 mesh sieved betel nut residue with a mass ratio of 2:1, the mass ratio of the mixed solvent to the mixture 2:1, the initial concentration of betel nut dregs is 30 mg mL -1 , 40KHz, 480W ultrasonic stripping for 2.5 hours, 5000 rpm, 45 min centrifugation to remove unpeeled betel nut residue, and collect the suspension to obtain the functionalized cellulose dispersion. The relevant performance parameters are shown in Table 1.

Embodiment 3

[0028] In the mixed solvent of nitric acid and tetramethylpiperidine nitrogen oxide in a volume ratio of 1:1, add the mixture of potassium sodium tartrate and 200 mesh sieved betel nut residue with a mass ratio of 2:1, the mass of the mixed solvent and the mixture The ratio is 2:1, the initial concentration of betel nut residue is 30 mg mL -1 , 40KHz, 480W ultrasonic stripping for 2 hours, 5000 rpm, 45 min centrifugation, remove the unpeeled betel nut residue, collect the suspension to obtain the functionalized cellulose dispersion. The relevant performance parameters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com