Novel high-reliability IGBT and manufacturing method thereof

A manufacturing method and reliability technology, applied in the new high-reliability IGBT and its manufacturing field, can solve the problems affecting the long-term reliability of the device, high doping concentration, etc., so as to improve the long-term reliability, reduce the impact, and improve the oxide layer. The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

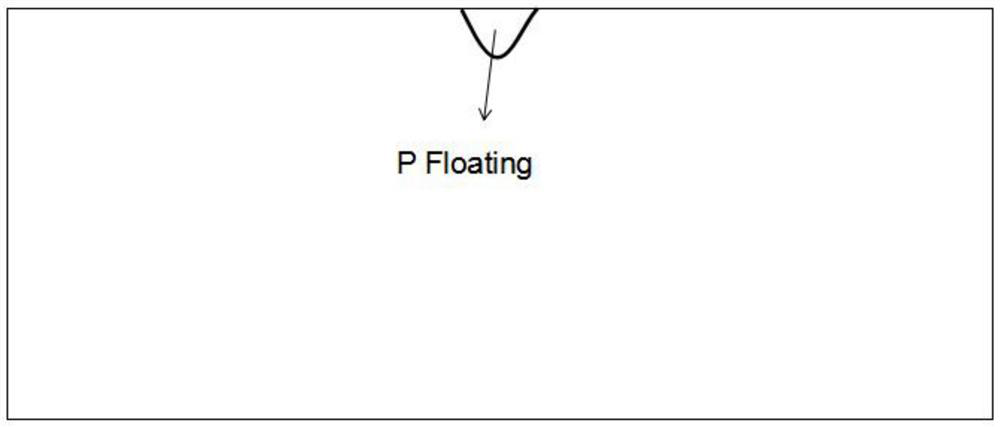

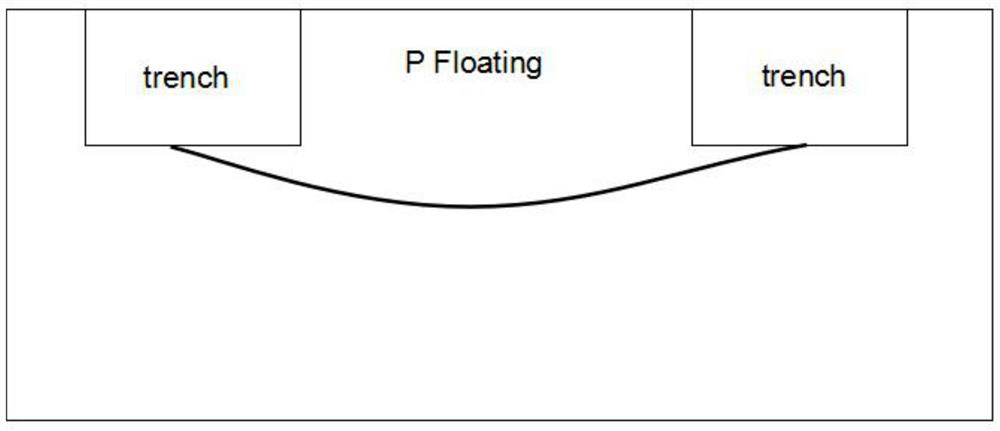

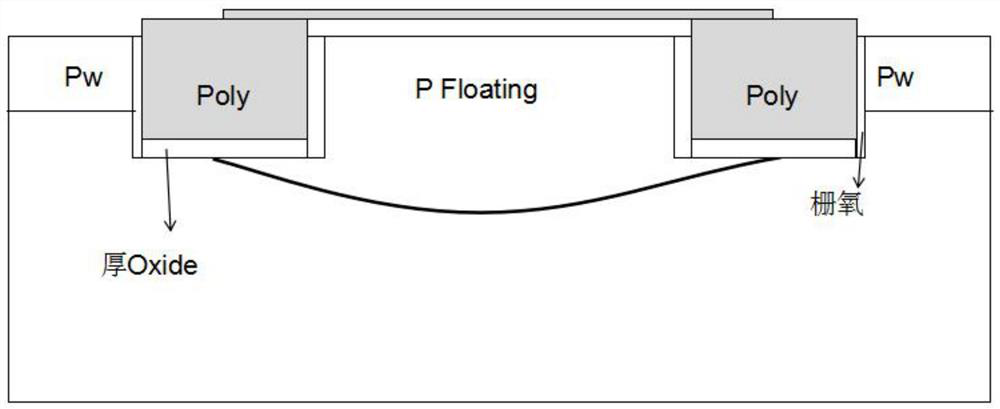

[0046] see figure 1 and figure 2 , a manufacturing method of a novel high-reliability IGBT, the following steps:

[0047] S1: Select a wafer substrate, open the area to be etched on the surface of the wafer substrate through a photolithography plate, and inject Boron ions, then form a dummy area through high temperature annealing, and deposit a certain thickness of oxide layer to cover the etching area.

[0048] Specifically, in one embodiment, the wafer substrate is an Fz wafer with a resistivity of 30Ω·cm. In other embodiments, the resistivity of the wafer substrate can also be 40Ω·cm, 50Ω·cm, 60Ω·cm, 70Ω·cm, 80Ω·cm, 90Ω·cm, 100Ω·cm, 110Ω·cm, Any value in 120Ω·cm.

[0049] The method of opening the area to be etched on the surface of the wafer substrate includes using a Terminal Ring photolithography plate to open by means of gluing, exposure, and development.

[0050] In the above steps, the dose of Boron ion implantation ranges from 1e12 to 1e13, and the implantation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com