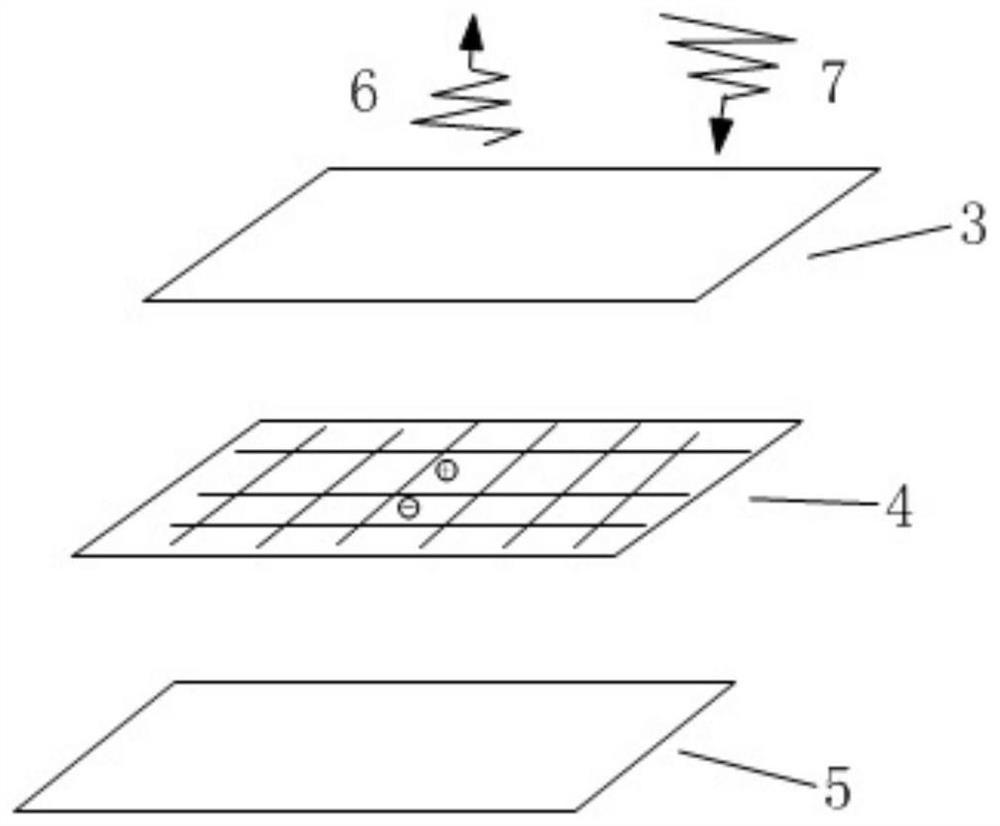

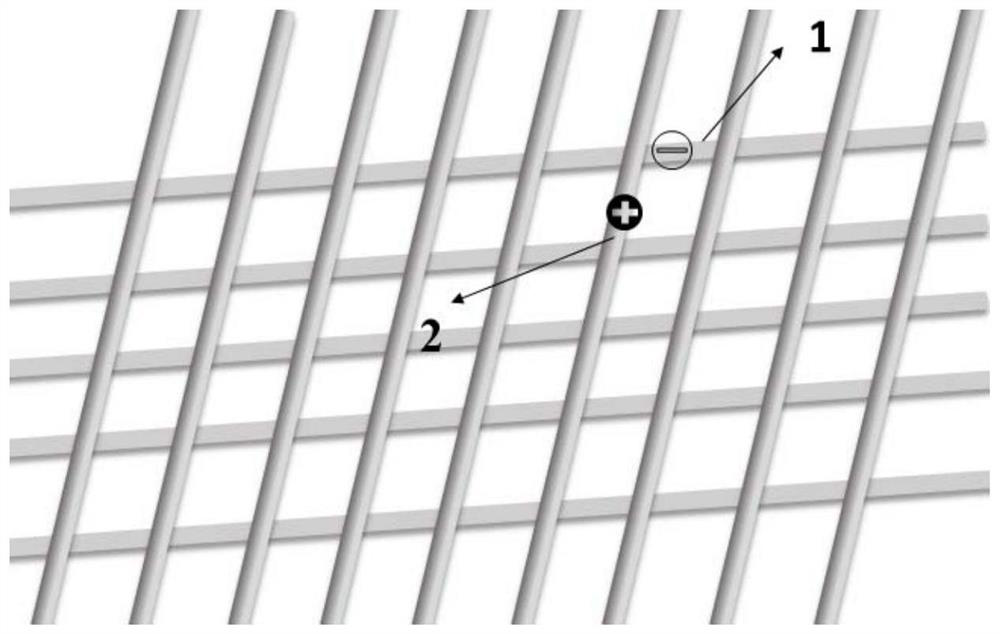

Mask based on electrostatic adsorption filtration and preparation method thereof

A technology of electrostatic adsorption and electrostatic filtration, which is applied in clothing, clothing, protective clothing, etc., and can solve problems such as poor wearing comfort, lack of layer-to-layer coordination, and no bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

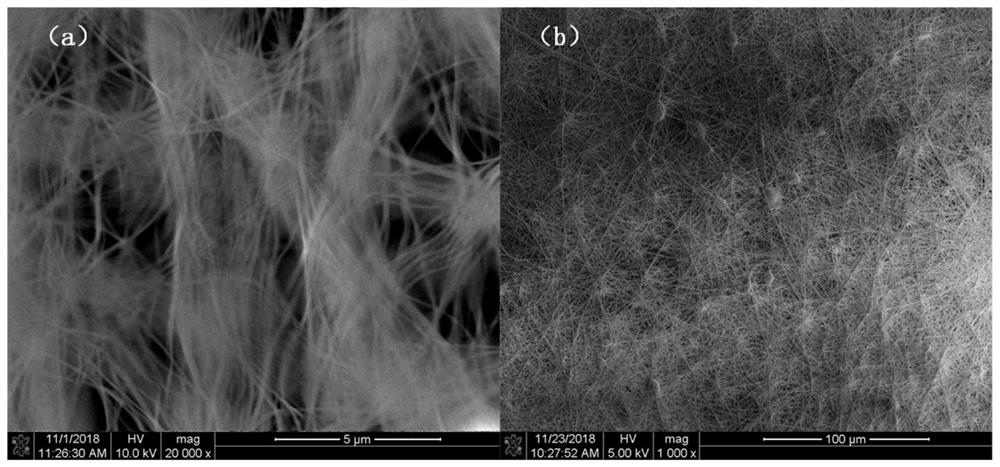

Embodiment 1

[0033] (1) Use a graduated cylinder to take 10ml of DMF and place it in a 25ml beaker, add 0.8g of PVA to the above solution, stir the solution at 30° for 4 hours to form a uniform and transparent colloidal solution, and put the colloidal solution at 12kv Next, the acceptance distance was adjusted to 12 cm, electrospinning was performed at an injection speed of 0.4 ml / h, and the textile was dried in a vacuum environment at 80°.

[0034](2) Measure 10ml of deionized water solution, transfer it to a 25ml beaker, weigh 1g of polyacrylamide (APAM) and add it to deionized water, stir the solution for 2 hours to form a clear solution. Then disperse 0.8g of PVP in deionized aqueous solution to form a uniform and stable colloidal solution, which forms an anionic polymer precursor solution, which is marked as solution a.

[0035] (3) Measure 10 ml of deionized water solution, transfer it to a 25 ml beaker, weigh 1 g of polyquaternium salt and add it to deionized water, stir the solutio...

Embodiment 2

[0039] (1) Use a graduated cylinder to take 10ml of DMF and place it in a 25ml beaker, add 0.8g of PVA to the above solution, stir the solution at 30 ° for 4 hours to form a uniform and transparent colloidal solution, and put the colloidal solution at 12kv Next, the receiving distance was adjusted to 12 cm, electrospinning was performed at an injection speed of 0.4 ml / h, and the textile was dried in a vacuum environment at 80°.

[0040] (2) Measure 10ml of deionized water solution, transfer it to a 25ml beaker, weigh 1.2g of polyacrylamide (APAM) and add it to deionized water, stir the solution for 2 hours to form a clear solution. Then disperse 1g of PVP in deionized aqueous solution to form a uniform and stable colloidal solution, which forms an anionic polymer precursor solution, which is marked as solution a.

[0041] (3) Measure 10ml of deionized water solution, transfer it to a 25ml beaker, weigh 1.2g of polyquaternium salt into deionized water, and stir the solution for...

Embodiment 3

[0045] (1) Use a graduated cylinder to take 10ml of DMF and place it in a 25ml beaker, add 0.8g of PVA to the above solution, stir the solution at 30 ° for 4 hours to form a uniform and transparent colloidal solution, and put the colloidal solution at 12kv Next, the acceptance distance was adjusted to 12 cm, electrospinning was performed at an injection speed of 0.4 ml / h, and the textile was dried in a vacuum environment at 80°.

[0046] (2) Measure 10ml of deionized water solution, transfer it to a 25ml beaker, weigh 1.4g of polyacrylamide (APAM) into deionized water, stir the solution for 2 hours, and form a clear solution. Then disperse 1.2g of PVP in deionized aqueous solution to form a uniform and stable colloidal solution, which forms an anionic polymer precursor solution, which is marked as solution a.

[0047] (3) Measure 10ml of deionized aqueous solution, transfer it to a 25ml beaker, weigh 1.4g of polyquaternium salt into deionized water, and stir the solution for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com