Method for preparing 1,3-propylene glycol coupling bacteriophage produced by microbial fermentation

A technology of microbial fermentation and propylene glycol, applied in the field of bioengineering, can solve the problems of low phage titer, high cost of medium, and low culture density of host cells, so as to avoid the bacteria treatment steps, improve the infection effect, and shorten the infection the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Fermentation of 1,3-propanediol

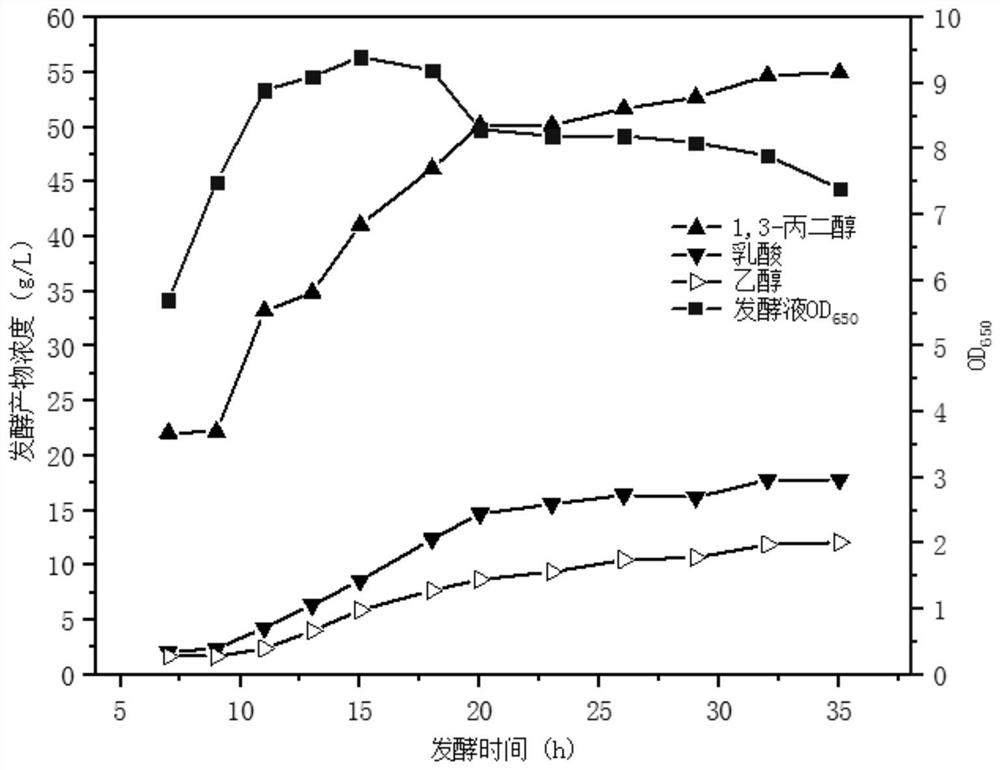

[0050] The fermentation experiment of this embodiment was carried out in a 5L fermenter, the initial fermentation medium volume of the fermenter was 2L, and the inoculum size was 10%. The initial glycerin concentration was 40g / L, and glycerol with a purity of 96% was added during the fermentation process to control the total residual glycerol concentration in the fermenter to be 15-20g / L. The temperature and rotational speed of the fermentation process were controlled at 37° C. and 250 rpm. The pH in the fermentation process was controlled at 7.0 by dropping 5mol / L NaOH solution. The changes of products and biomass during the fermentation process are shown in figure 1 shown. The host cell density reaches the maximum OD at 15 hours of fermentation 650 9.4, the concentration of 1,3-propanediol at the end of fermentation can reach up to 55g / L, and the production intensity is 1.57g / L / h.

Embodiment 2

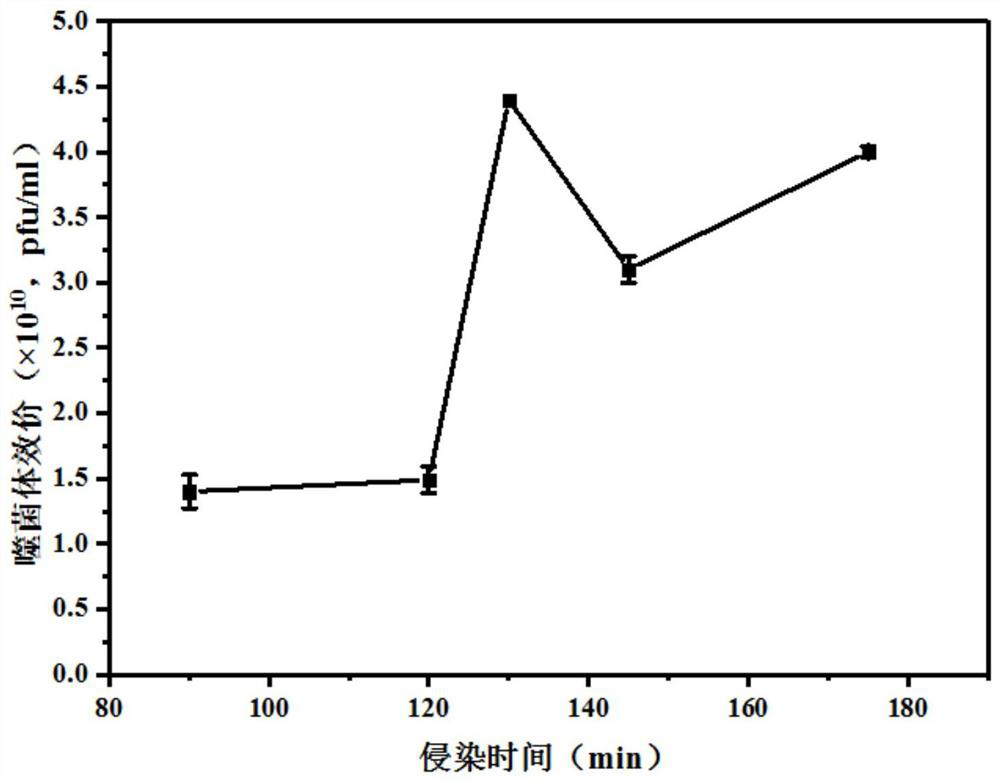

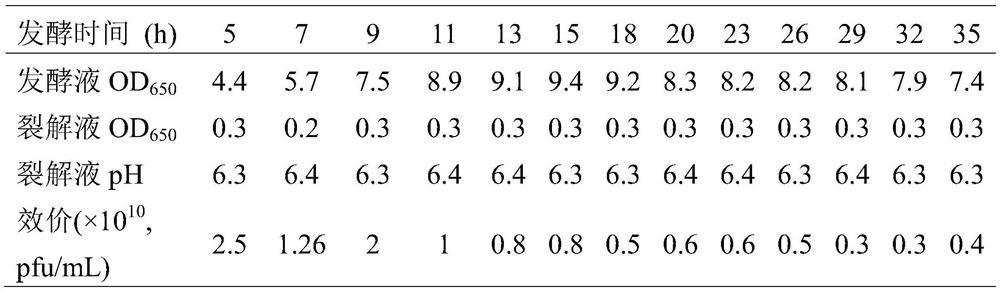

[0051] The preparation of embodiment 2 phage

[0052] According to the method described in Example 1, using glycerol as a substrate, the host bacteria were obtained by adding glycerol in batches, and a certain amount of host bacteria at different fermentation time points were taken respectively, centrifuged at 10000rpm for 10min, and the supernatant was mainly 1,3 -Products such as propylene glycol, the obtained bacteria sludge is used to mix with the phage suspension in a certain ratio, and the infection index (MOI) is 0.1, and the infection experiment is carried out. The infection experiment was carried out in a 150mL shake flask (working volume: 50mL), the culture medium was a fermentation medium with a glycerol concentration of 40g / L, and the culture conditions were 37°C and 200rpm. After 2.5h, the infection was terminated, and the phage lysate was obtained. The concentration of the lysate, the pH value of the lysate and the titer of the phage in the phage lysate are shown...

Embodiment 3M

[0055] The influence of embodiment 3MOI on phage infection

[0056] The host cells in the final stage of fermentation (35h) in Example 1 were taken for MOI optimization test, and four values of MOI=0.1, 0.05, 0.01, and 0.002 were respectively taken for infection test. OD of lysate obtained from infection 650 See Table 2 for values, pH and phage titers. When the MOI was 0.01, the phage titer was as high as 2.6×10 9 pfu / mL.

[0057] Table 2. Experimental results of infecting host cells at the end of fermentation at different MOIs

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com