Positive electrode slurry of water-based lithium iron phosphate battery and preparation method of positive electrode slurry

A lithium iron phosphate battery and positive electrode slurry technology, which is applied in the direction of electrode manufacturing, battery electrodes, active material electrodes, etc., can solve the problems of electrode cracking and powder loss, poor slurry stability, and poor flexibility of positive electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

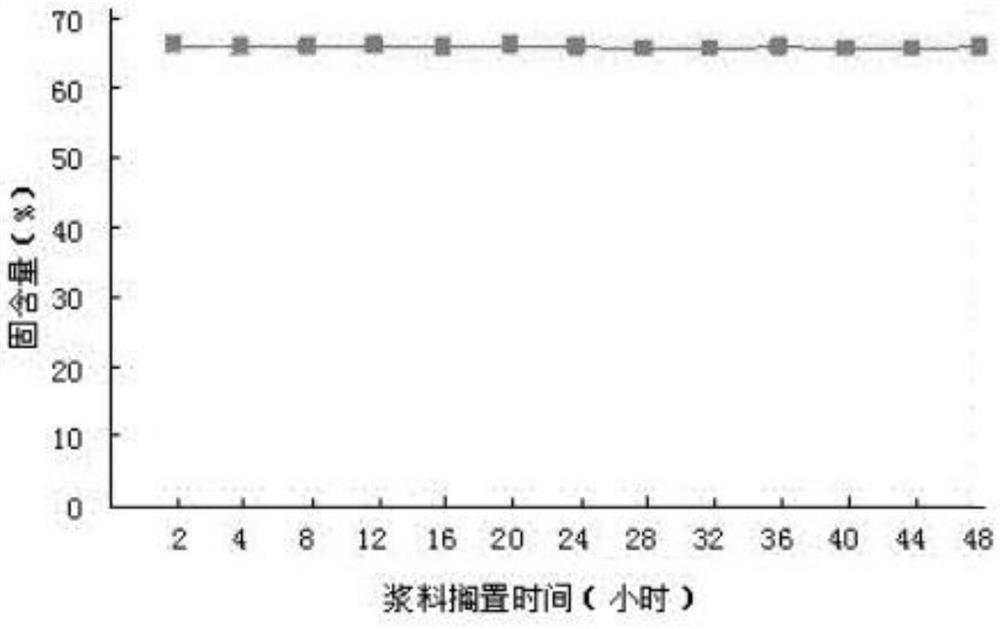

Image

Examples

Embodiment 1

[0043] A positive electrode slurry for an aqueous lithium iron phosphate battery, comprising a positive electrode active material, a conductive agent and a binding agent, the binding agent comprising a binding agent A and a binding agent B, by weight, the positive electrode active material: viscose Bonding agent A: binder B: conductive agent = 93:1:3:3;

[0044] The positive electrode active material is lithium iron phosphate; the main chain of the binder A is polyethylene glycol, and the branch chain is acrylate; the binder B is a copolymer of acrylic acid and acrylonitrile. Tougheners were also added to Binder B. The toughening agent is polymethyl methacrylate.

[0045]A method for preparing lithium iron phosphate, comprising: respectively providing a lithium source solution, a ferrous source solution, and a phosphorus source solution, wherein the lithium source solution, the ferrous source solution, and the phosphorus source solution are respectively a lithium source compo...

Embodiment 2

[0056] Referring to Example 1, different from Example 1, the lithium source for preparing aqueous lithium iron phosphate comes from a mixture of lithium carbonate and lithium hydroxide; the weight ratio of lithium carbonate and lithium hydroxide is 70:30. Tougheners were also added to Binder B. The toughening agent is polypropylene butyl ester.

Embodiment 3

[0058] Referring to Example 1, different from Example 1, the lithium source for preparing aqueous lithium iron phosphate comes from a mixture of lithium carbonate and lithium hydroxide; the weight ratio of lithium carbonate and lithium hydroxide is 80:40. Tougheners were also added to Binder B. The toughening agent is a mixture of polymethyl methacrylate and polypropylene butyl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Reverse discharge specific capacity | aaaaa | aaaaa |

| Reverse discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com