Vehicle-mounted sulfur, nitrate, dust and fluorine integrated deep purification device and using method

A deep purification device and vehicle-mounted technology, which is applied in the field of flue gas purification, can solve problems such as low purification efficiency, increase operating costs, and prolong dust removal time, and achieve good treatment effects, improve purification efficiency, and high dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

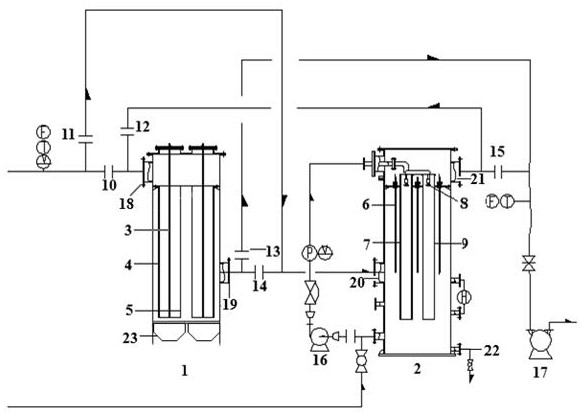

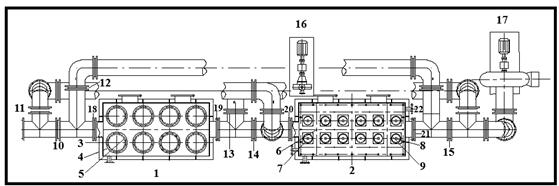

[0029] Embodiment 1: as figure 1 , 2 As shown, the device in this embodiment includes a locomotive, a container connected behind the locomotive, and a purification system, and the purifying system is arranged in the container; the purifying system includes a purification tower I1 and a purification tower II2; wherein the purification tower I1 includes a tower body I, an electric Corona electrode Ⅰ3, conductive filter 4, filter cloth Ⅰ5; purification tower Ⅱ2 includes tower body Ⅱ, corona electrode Ⅱ6, filter cloth Ⅱ7, spray system 8, electric filter coupling body 9; the upper part of tower body Ⅰ is provided with an air inlet Ⅰ, the inlet pipe is connected to the inlet Ⅰ of the tower body Ⅰ through the valve Ⅰ10, and the lower part of the tower body Ⅰ is provided with the gas outlet Ⅰ, and the gas outlet Ⅰ is connected with the gas inlet Ⅱ of the purification tower Ⅱ2 through the valve Ⅴ14, and 6 conductive The filter body 4 is set in the tower body I through the bracket, the...

Embodiment 2

[0032] Embodiment 2: The structure of the device used in this embodiment is the same as in Embodiment 1; the difference is that the purification tower I1 does not include filter cloth I5;

[0033] In actual operation, valve I10 is closed, valve II11 is opened, valve V14 is closed, valve III12, valve IV13 are opened, and valve VI15 is closed; in this way, the series operation of purification tower II2 and purification tower I1 is realized, and the gas first passes through purification tower II2 , and then through the purification tower I1;

[0034] The flue gas from silicon smelting at 200°C is passed through the valve II11 into the purification tower II2, in which the SO in the flue gas 2 The concentration is 1000mg / m 3 , NO x The concentration is 750mg / m 3 , The particle concentration is 2000mg / cm 3 ; The flue gas enters the charging area first, and the cathode corona electrode II 6 in the charging area adopts a needle-shaped electrode, and the anode electric filter coupl...

Embodiment 3

[0036] Embodiment 3: The structure of the device used in this embodiment is the same as in Embodiment 1;

[0037] In actual operation, the valve II11 and the valve III12 are replaced by flange blind plates to close, valve I10 is replaced by flanges to open, valve IV13 is replaced by flange blind plates to close, valve V14 is replaced by flanges to open, and valves Ⅵ15 is replaced by a flange and opened; in this way, the series operation of the purification tower I1 and the purification tower II2 is realized, and the gas first passes through the purification tower I1, and then passes through the purification tower II2.

[0038] Pass the 460°C zinc smelting flue gas into the purification tower I1 through the flange 10, where the flue gas velocity is 5m / s, and the concentration of particulate matter in the flue gas is 1200 mg / cm 3 , SO in flue gas 2 The concentration is 1000mg / m 3 The corona electrode Ⅰ3 in the charging area adopts a needle-shaped electrode, and the electrode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com