Phosphonated hyperbranched polybenzimidazole-polysiloxane block copolymer as well as preparation method and application thereof

A technology of polybenzimidazole block and polysiloxane block, which is applied in the field of phosphonated hyperbranched polybenzimidazole-polysiloxane block copolymer and its preparation, can solve phosphoric acid loss and proton conductivity drop and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

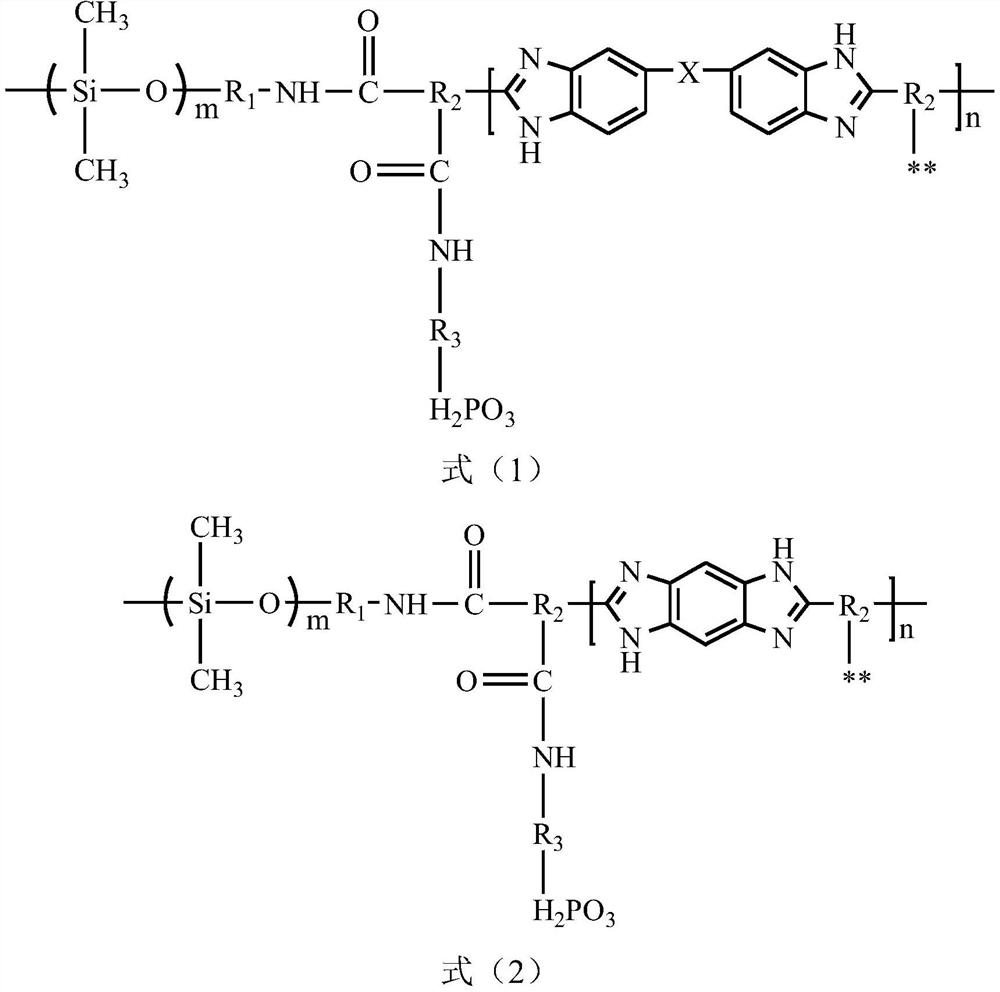

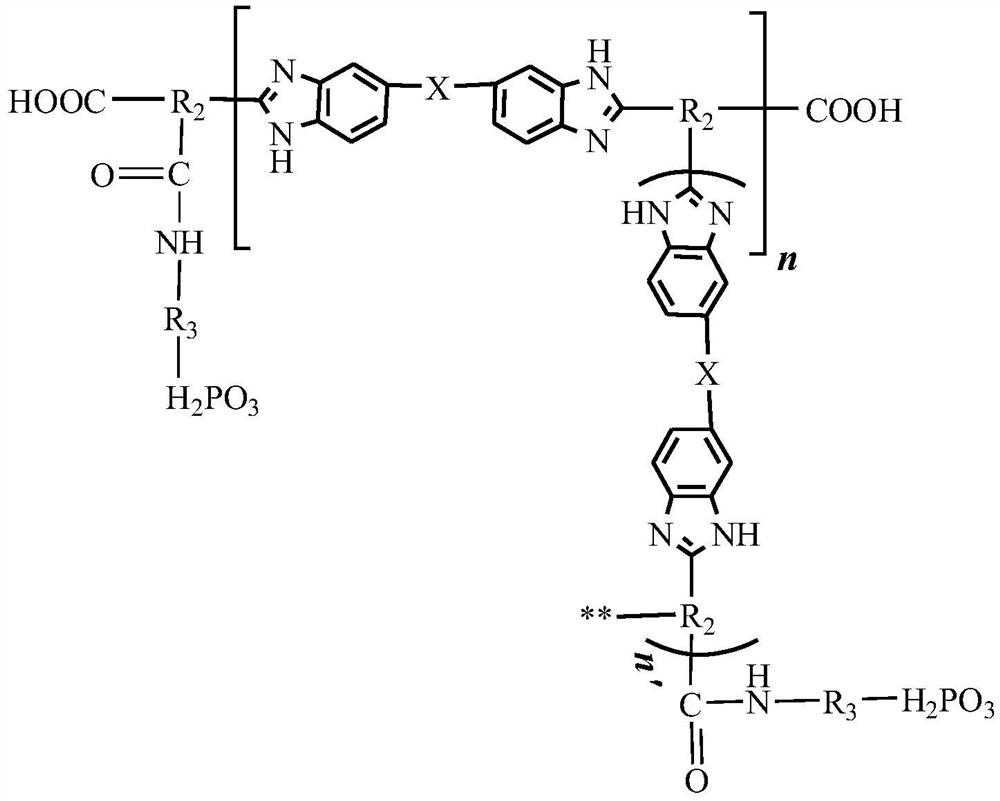

[0106] The present invention also provides a kind of preparation method of above-mentioned block copolymer, it comprises the steps:

[0107] The block copolymer is prepared by dissolving the partially phosphonated hyperbranched benzimidazole polymer containing carboxyl groups and the polysiloxane containing double-terminal amino groups in an organic solvent and reacting at high temperature.

[0108] Wherein, the reaction is carried out under the heating condition of 120-160° C. under the protection of inert gas; specifically, the reaction time is 6-15 hours.

[0109] Wherein, the organic solvent is one or more combinations of the following: DMF (N,N-dimethylformamide), DMAc (N,N-dimethylacetamide), DMSO (dimethylmethylene sulfone), NMP (N,N-dimethylpyrrolidone), polyphosphoric acid, methanesulfonic acid, TFA (trifluoroformic acidsulfonic acid), preferably DMF or DMAc.

[0110] Wherein, the molar ratio of the carboxyl-containing partially phosphonated hyperbranched benzimidazo...

Embodiment 1

[0153] (1) Add 378g of polyphosphoric acid (PPA) to a dry three-necked flask, then add 2.142g of 3,3-diaminobenzidine (DAB) and trimesic acid (BTA) at the same time in a molar ratio of 1:0.8 ) 1.68g, and the reaction solid content was 1.0%. The temperature was raised to 150°C and maintained in a nitrogen atmosphere for 3h, and then heated to 200°C for 8h.

[0154] (2) Lower the temperature of the above solution to 120°C, then add 0.80g of alendronic acid (the molar ratio to BTA is 0.4:1), raise the temperature to 190°C for 4 hours, then precipitate in deionized water, and Washing with deionized water multiple times to obtain carboxyl-containing partially phosphonated hyperbranched benzimidazole polymer LHBPBI;

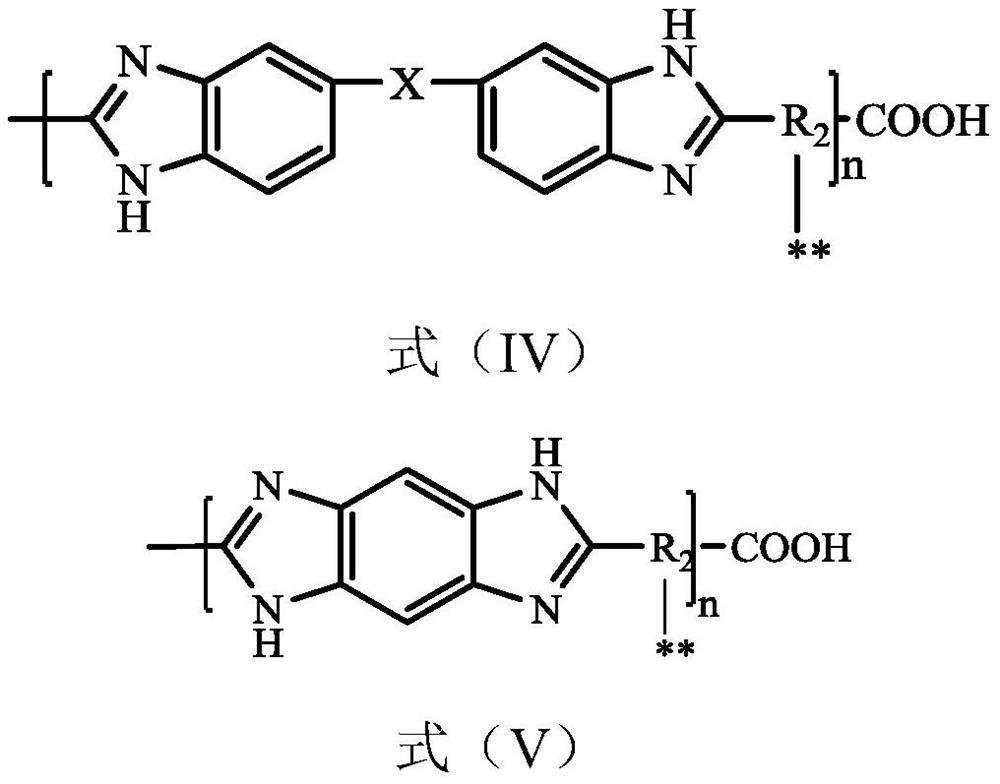

[0155] Its structure is as described in formula (b):

[0156]

[0157] (3) Take 2.76g of LHBPBI (Mv=4.6kDa) from step (2) and dissolve it in DMAc (5wt%), then add 0.2g of double-terminal amino PDMS (shown in formula (a), Mn=10k, 0.02mmol) , and then inert gas arg...

Embodiment 2

[0163] (1) Same as Example 1, except adding 2.142g of DAB and 1.89g of BTA with a molar ratio of 1:0.9.

[0164] (2) Same as Example 1, except that 1.40 g of alendronic acid was added (the molar ratio to BTA was 0.62:1).

[0165] (3) Same as Example 1, 3.16g of LHBPBI (Mv=7.9kDa) from step (2) was dissolved in DMAc (5wt%), and then 0.34g of double-terminal amino PDMS (Mn=17k, 0.02mmol) was added.

[0166] After testing and calculation, the storage modulus of the polymer film not impregnated with phosphoric acid is 580MPa at 180°C, the ADL of the film impregnated with phosphoric acid is 10.20, the proton conductivity is 0.0814S / cm, and the proton conductivity per unit phosphoric acid doping level 0.00798S / cm, 0.0627S / cm proton conductivity after 10 immersions in deionized water, and 77.1% proton conductivity retention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com