Heat-resistant environment-friendly flame-retardant cable insulation material and preparation method thereof

A technology for flame retardant cables and insulating materials, applied in the field of cables, can solve the problems that polyolefin materials are difficult to have high flame retardant level, high cost, high cost of irradiation equipment, and achieve excellent processing performance and mechanical properties, low cost, The effect of superior heat resistance and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

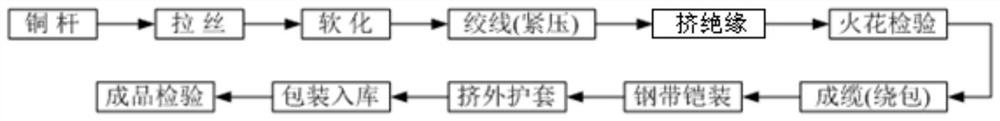

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a heat-resistant, environmentally friendly and flame-retardant cable insulation material, the formula raw materials of which include:

[0045] polyvinyl chloride resin,

[0046] heat-resistant plasticizer,

[0047] flame retardant,

[0048] Heat stabilizers,

[0049] filler,

[0050] Antioxidant,

[0051] Processing aids,

[0052] lubricant,

[0053] Colorant,

[0054] Wherein, the heat-resistant plasticizer includes: trioctyl trimellitate (TOTM) and / or tridecyl trimellitate.

[0055] This embodiment also provides a method for preparing the above-mentioned heat-resistant and environmentally friendly flame-retardant cable insulation material, which includes the following steps:

[0056] Add the above-mentioned formula raw materials of heat-resistant, environmentally friendly and flame-retardant cable insulation materials into the mixer and mix them, and discharge them at 110-125°C; carry out extrusion and mastication through a twin-screw ...

Embodiment 2

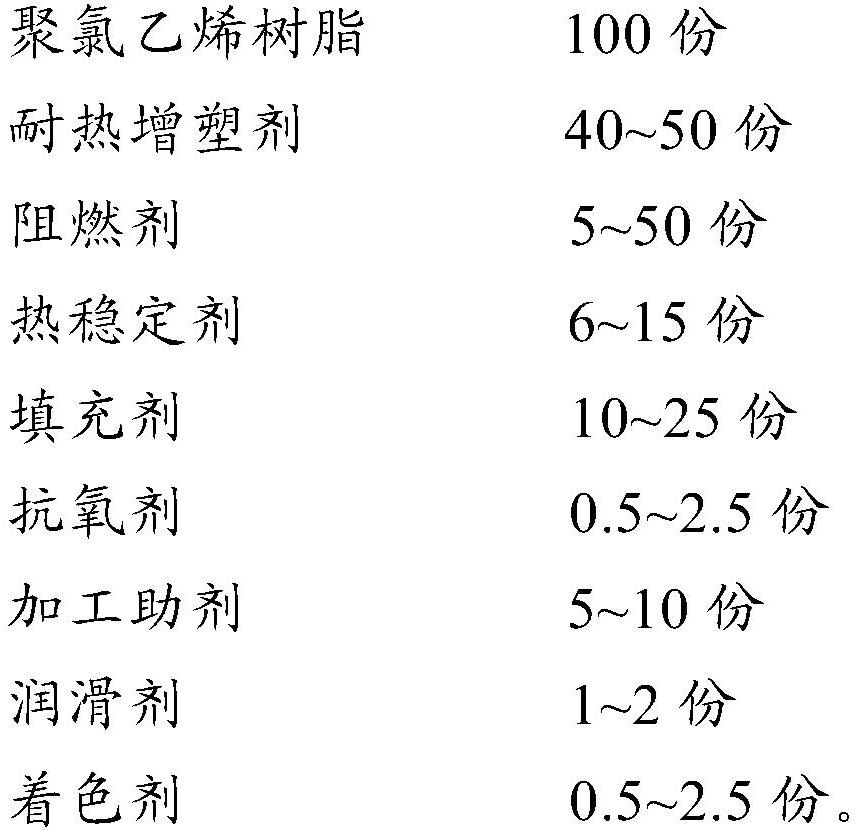

[0059] This embodiment provides a heat-resistant, environmentally friendly and flame-retardant cable insulation material, the weight ratio of the formula raw materials is as follows:

[0060]

[0061]

[0062] It should be noted that the polyvinyl chloride resin in this embodiment is a suspension-process polyvinyl chloride resin, a mixture of polyvinyl chloride resins with a degree of polymerization of 2500 and 2000, and the weight ratio of the two is 50:50.

[0063] It should be noted that the heat-resistant plasticizer in this embodiment is a mixture of trioctyl trimellitate, tridecyl trimellitate, and epoxy soybean oil, and the weight ratio of the three is 20:25:4 .

[0064] It should be noted that the flame retardant in this embodiment is a mixture of antimony trioxide, zinc borate, and magnesium hydroxide, and the weight ratio of the three is 8:8:10.

[0065]It should be noted that the heat stabilizer in this example is an organic calcium-zinc composite stabilizer....

Embodiment 3

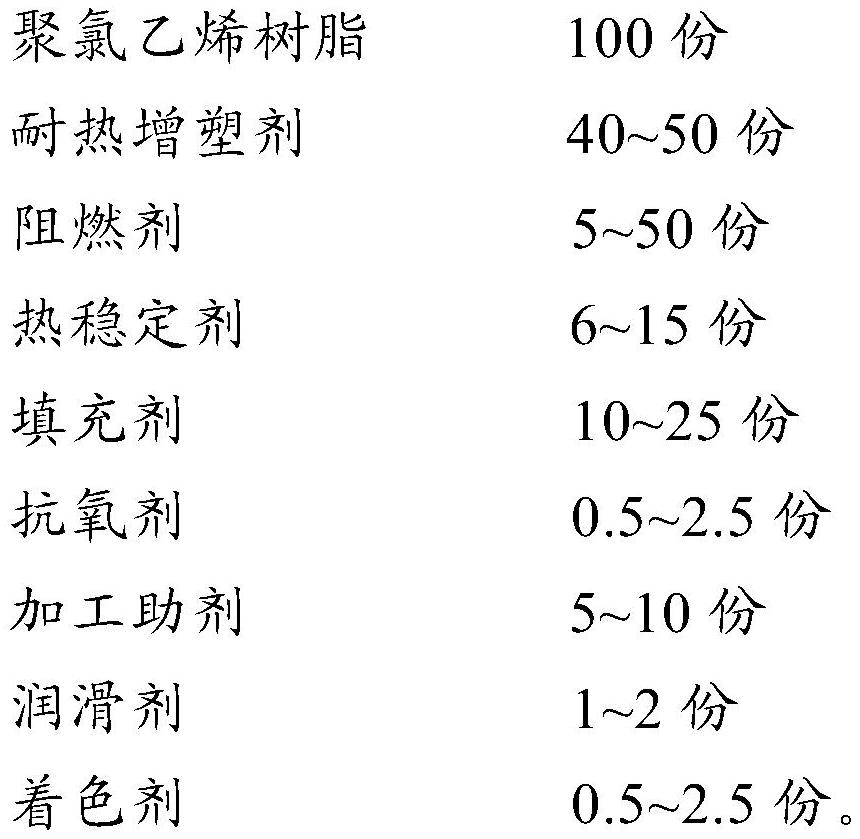

[0088] This embodiment provides a heat-resistant, environmentally friendly and flame-retardant cable insulation material, the weight ratio of the formula raw materials is as follows:

[0089]

[0090] It should be noted that the polyvinyl chloride resin in this embodiment is a suspension polyvinyl chloride resin, a mixture of polyvinyl chloride resins with a degree of polymerization of 2500 and 2000, and the weight ratio of the two is 40:60.

[0091] It should be noted that the heat-resistant plasticizer in this embodiment is a mixture of trioctyl trimellitate, tridecyl trimellitate, and epoxy soybean oil, and the weight ratio of the three is 15:30:4 .

[0092] It should be noted that the flame retardant in this embodiment is a mixture of antimony trioxide, zinc aluminate, and aluminum hydroxide, and the weight ratio of the three is 6:6:15.

[0093] It should be noted that the heat stabilizer in this example is an organic calcium-zinc composite stabilizer.

[0094] It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com