A low dielectric loss polytetrafluoroethylene microwave plate and its preparation method

A polytetrafluoroethylene and polyperfluoroethylene propylene technology, which is applied in the field of low dielectric loss polytetrafluoroethylene microwave sheet and its preparation, can solve the problem of poor mechanical properties of copper clad laminate materials, poor material bonding performance, and bonding degree. It can simplify the preparation scheme, improve the dielectric loss, and improve the dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

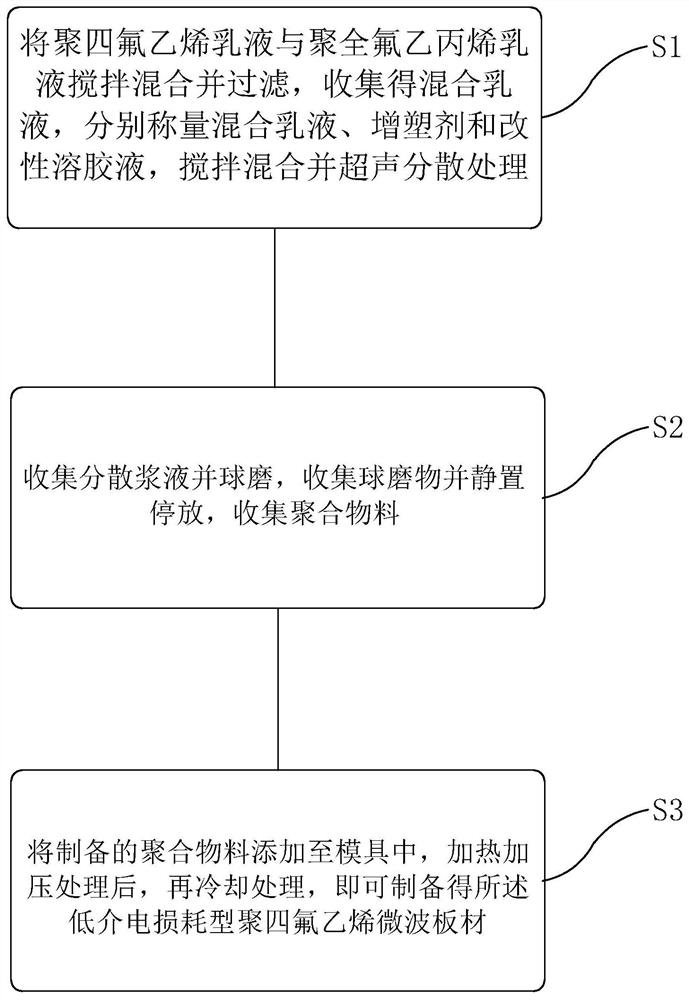

Method used

Image

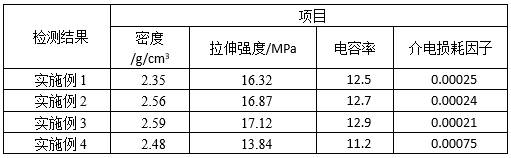

Examples

Embodiment 1

[0031] S1. In parts by weight, weigh 45mL of absolute ethanol, 10mL of deionized water, 6mL of glacial acetic acid and 1mL of ionic liquid in a blender, stir and mix at room temperature for 25min, and collect the modified mixture; Ratio 1:5:10, add ionic liquid and tetrabutyl titanate to absolute ethanol, stir and mix and collect the base liquid; the ionic liquid is 1-butyl-3-methylimidazolium tetrafluoroboric acid salt ionic liquid;

[0032] S2. According to the mass ratio of 1:5, drop the modified mixed solution into the base liquid, control the dropping rate at 0.05mL / min, and control the stirring rate at 250r / min during the dropping, after the dropping is completed, let stand Aging for 25min, centrifugation at 2000r / min and removal of the supernatant, the modified sol was collected;

[0033] S3. According to the mass ratio of 6:1, the viscosity is 5×10 -3 Pas, polytetrafluoroethylene emulsion with a solid content of 60% and a viscosity of 2×10 -3Pas and polyperfluoroeth...

Embodiment 2

[0037] S1. Weigh 47 mL of absolute ethanol, 12 mL of deionized water, 7 mL of glacial acetic acid and 1 mL of ionic liquid, respectively, and place them in a mixer. After stirring and mixing at room temperature for 27 minutes, the modified mixed solution is collected; according to the mass ratio of 1:5:10 , adding the ionic liquid and tetrabutyl titanate to absolute ethanol, stirring and mixing and collecting the matrix liquid; the ionic liquid is 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid;

[0038] S2. Add the modified mixture dropwise to the base liquid at a mass ratio of 1:5, control the drop rate to be 0.05mL / min, and control the stirring rate to be 275r / min during dropwise addition. After the dropwise addition is completed, let stand Aged for 27min, centrifuged at 2500r / min and removed the supernatant to collect the modified sol;

[0039] S3. According to the mass ratio of 6:1, take the viscosity of 5×10 -3 Pas, 65% solids PTFE emulsion with viscosity 2×1...

Embodiment 3

[0043] S1. Weigh 50 mL of absolute ethanol, 15 mL of deionized water, 8 mL of glacial acetic acid and 2 mL of ionic liquid, respectively, and place them in a mixer. After stirring and mixing at room temperature for 30 minutes, the modified mixed solution is collected; the mass ratio is 1:5:10 , adding the ionic liquid and tetrabutyl titanate to absolute ethanol, stirring and mixing and collecting the matrix liquid; the ionic liquid is 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid;

[0044] S2. Add the modified mixture dropwise to the base liquid at a mass ratio of 1:5, control the drop rate to be 0.05mL / min, and control the stirring rate to be 300r / min during dropwise addition. After the dropwise addition is completed, let stand Aged for 30min, centrifuged at 3000r / min and removed the supernatant to collect the modified sol;

[0045] S3. According to the mass ratio of 6:1, take the viscosity of 5×10 -3 Pas, 65% solids PTFE emulsion with viscosity 2×10 -3 Pas and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com