A method of on-line pickling and slag removal device

A pickling and line acid technology, applied in the direction of liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small space, reducing the working current of slag removal pumps and overflow pumps, and reducing work efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

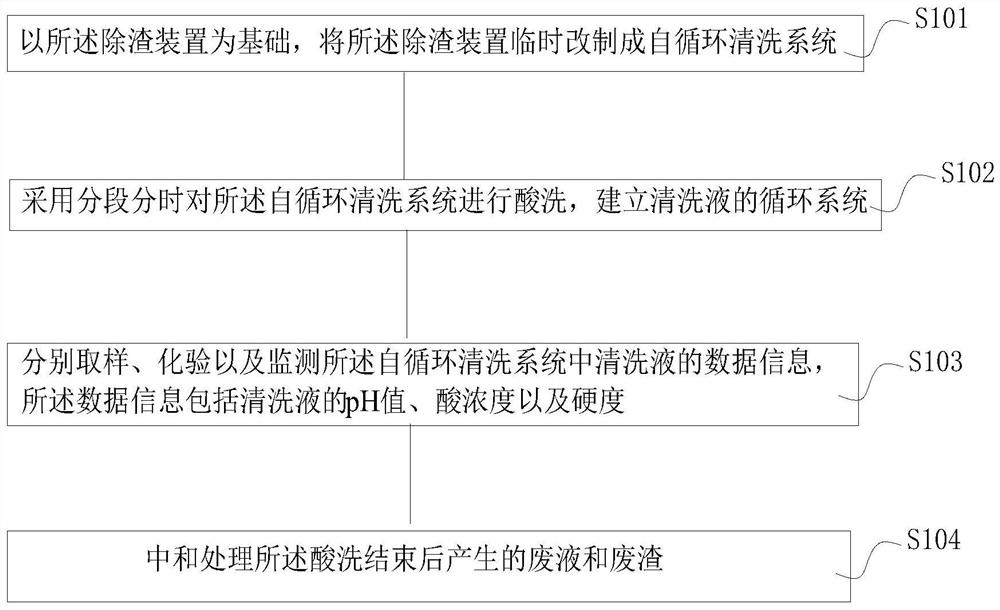

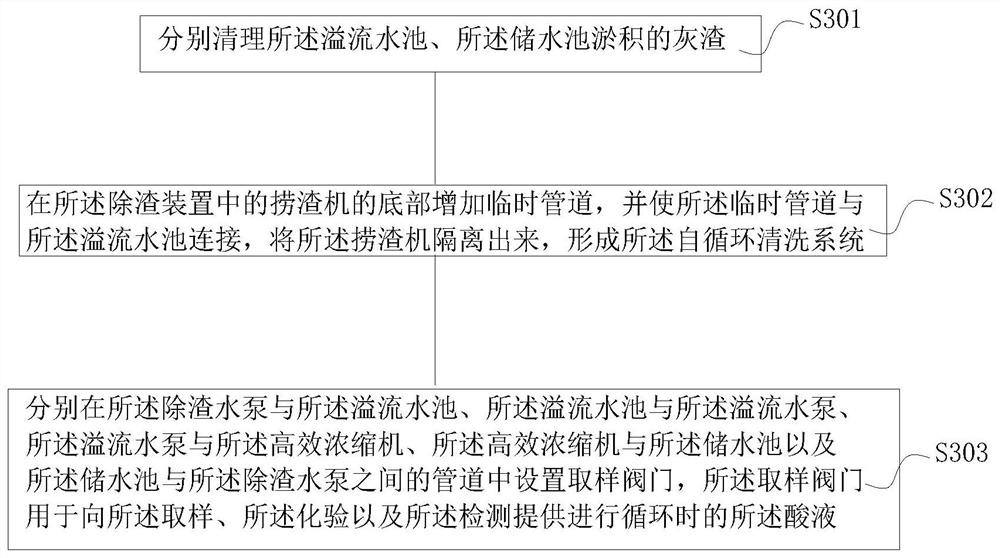

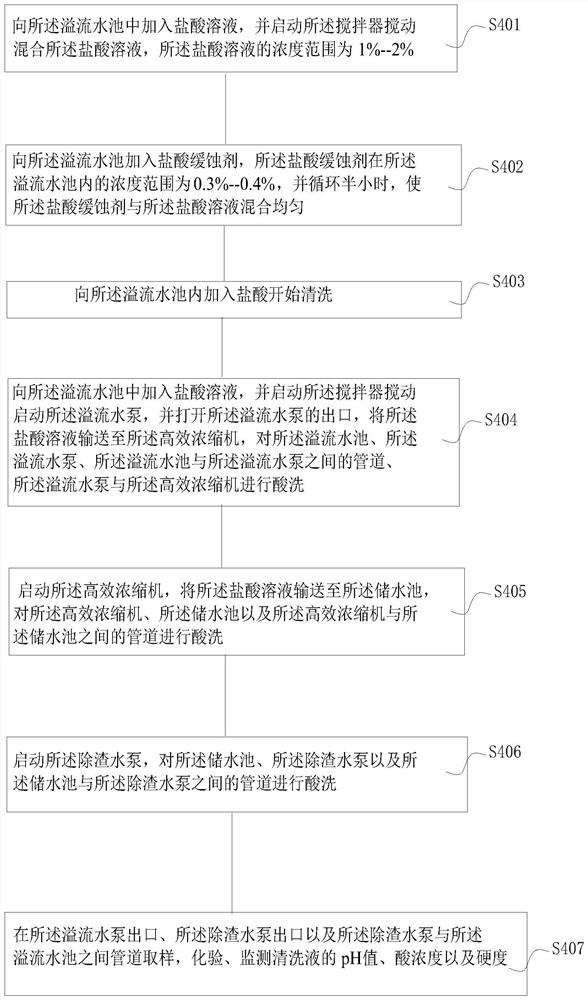

[0042] The following is combined with the attached Figure 1 、 Figure 2 、 Figure 3 、 Figure 4 and Figure 5 The present invention will be further described in detail.

[0043] A method of online pickling slag removal device, using a semi-start cycle cleaning method to pickling the slag removal device online, online pickling is the use of the slag removal device itself, adding acid to the slag removal device for cleaning, such as Figure 1 shown, which includes the following steps:

[0044] Based on the slag removal device, the S101 temporarily converts the slag removal device into a self-circulation cleaning system.

[0045] S102 adopts segmented time-sharing to pickle the self-circulation cleaning system to establish a circulation system of the cleaning liquid.

[0046] S103 separately samples, tests and monitors the data information of the cleaning solution in the self-circulation cleaning system, including the pH value, acid concentration and hardness of the cleaning liquid.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com