Movable integrated modular mechanism reclaimed sand device

A mobile, regenerated sand technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as inability to meet work efficiency and environmental requirements, high production site conditions, and long equipment installation time. , to achieve the effect of high construction efficiency, flexible appearance and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

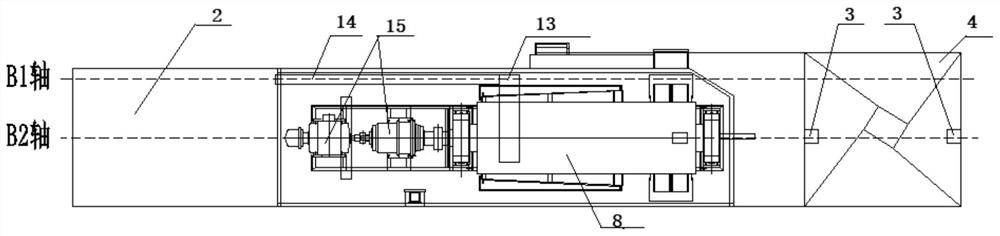

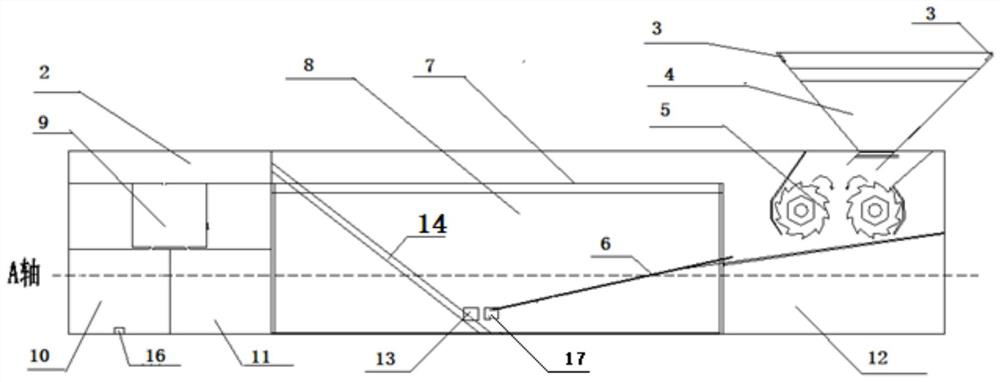

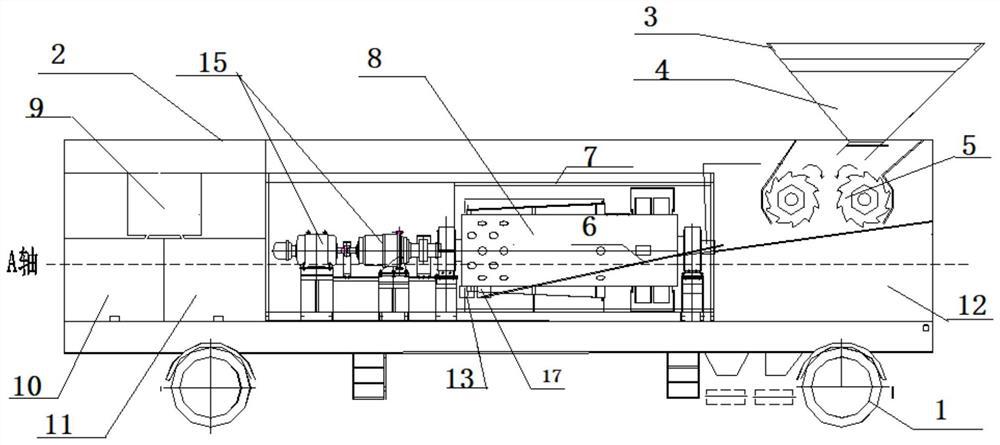

[0039] like Figure 1 to Figure 4 As shown, a mobile integrated modular mechanism reclaimed sand device includes a movable wheeled container, a flatbed trailer, a crusher, a belt elevator and a drum sand making machine; the specific composition and structure are as follows:

[0040] (1) The movable wheeled container is to reinforce the structure of the standard container, and the container 2 is fixed on the corresponding flatbed trailer 1, and the flatbed trailer 1 is non-independently suspended by an oil-gas spring to realize the whole set of equipment Stable, fast, flexible and mobile. In this embodiment, a standard 40-foot container box is rationally modified and structurally reinforced. The outer dimension is 12.2m×2.44m×2.59m, the inner volume is 11.8m×2.13m×2.18m, and the volume is about 54m 3 , the load limit is 22 tons. The movable wheeled container 2 is installed modularly to realize the flexible mobility of the production device. In this way, the equipment install...

Embodiment 2

[0053] Treat tailings in a certain place, the processing capacity is about 500m 3 , due to the large processing capacity, use 2 sets of this device. Device composition and structure are as embodiment 1, and processing flow is as follows:

[0054] (1) The device is transferred to the tailings site for assembly by using the flexible transition of the equipment. Due to the large processing capacity, two sets of devices are prepared, and the assembled area is about 100 square meters.

[0055] (2) Select 6 permanent magnet synchronous four-stage variable-frequency variable-speed motors with a rated power of 100kw and two 60kw permanent-magnet synchronous four-stage variable-frequency variable-speed motors with an installed power of 720kw, and use three-core cables to complete the connection of the drive circuit.

[0056] (3) Preliminary crushing of the waste at the tailings construction site, ensuring that the diameter of the waste is less than 1.2m when feeding, and then enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com