High-quality amidino perovskite FAPbI3 colloidal quantum dot and preparation method thereof

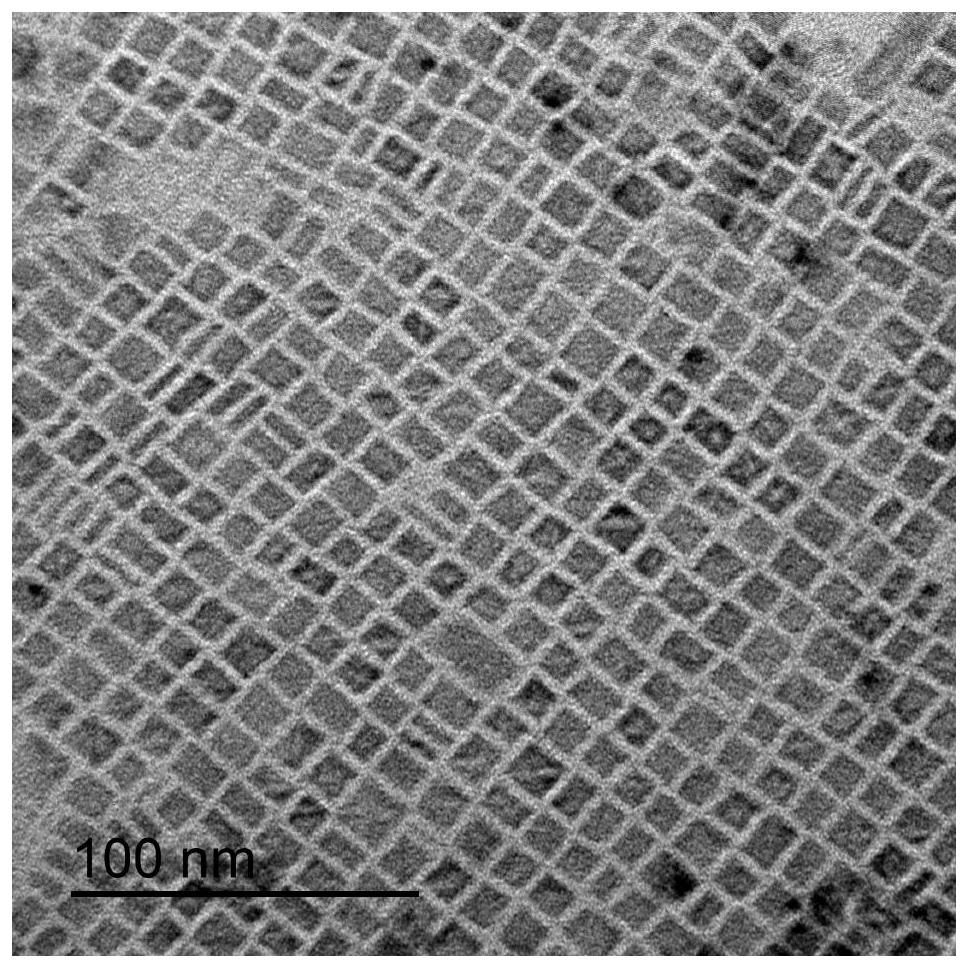

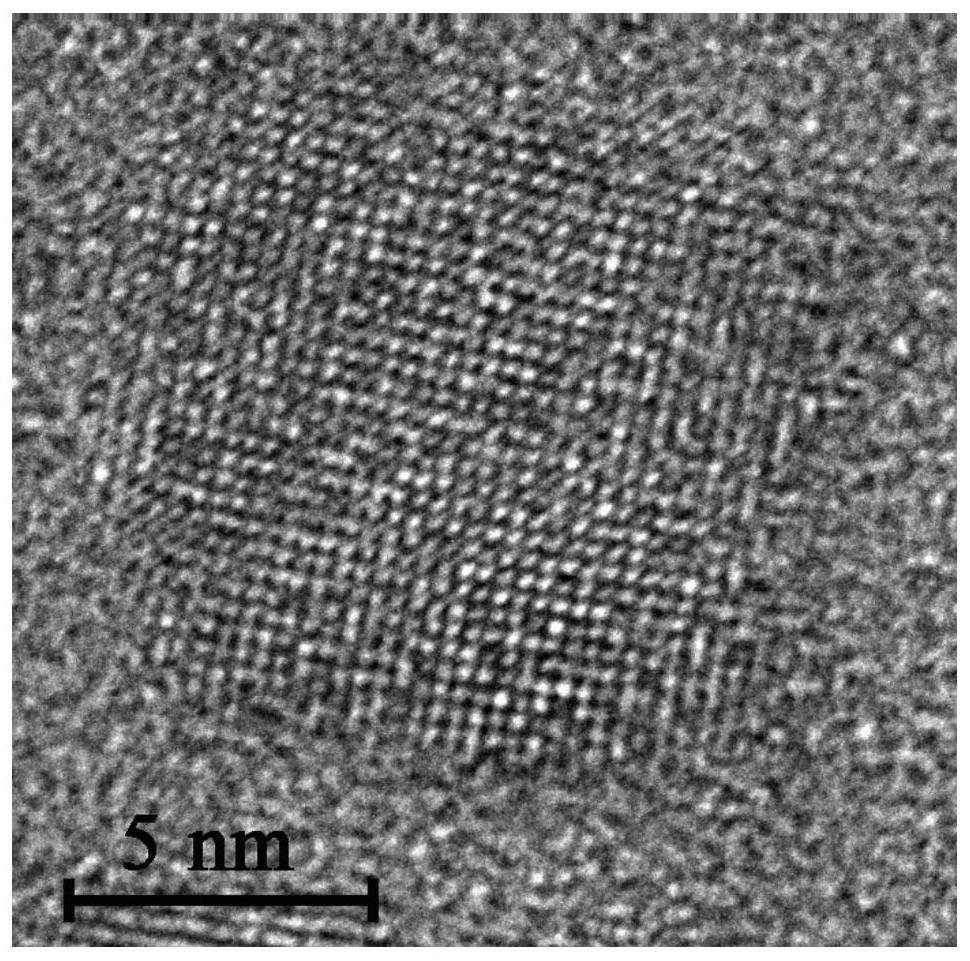

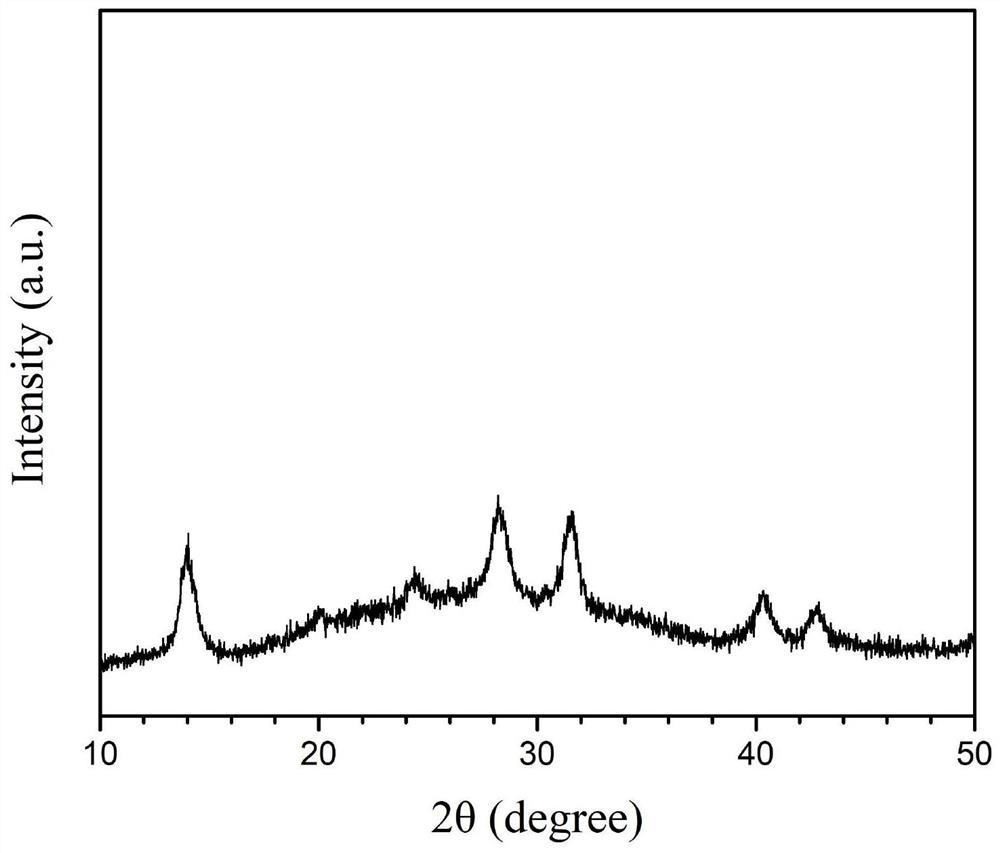

A technology of colloidal quantum dots and formamidinyl, applied in the field of high-quality FAPbI3 colloidal quantum dots and its preparation, can solve the problem of inability to accurately adjust the stoichiometric ratio of Pb and I elements, which is not conducive to the formation of tight and orderly arrangements, and is not conducive to the improvement of device efficiency and other problems, to achieve the effect of simple and easy operation, uniform appearance and tight arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Transfer 0.0380 g formamidine acetate (0.375 mmol) and 0.0427 g lead acetylacetonate (0.1 mmol) to a 25 ml round bottom flask, then add 4 ml 1-octadecene and 1 ml oleic acid, and transfer the mixture in the flask to Raise the temperature to 50°C under vacuum and keep it for half an hour, then continue to raise the temperature to 80°C under the protection of inert gas and maintain this temperature to completely dissolve the added raw materials to form a clear and transparent solution.

[0027] 2) Dissolve 0.1185 g (0.3 mmol) oleylamine-iodine in 1 ml of anhydrous toluene, and then quickly inject it into the solution in step 1). After 10 s, quickly transfer the flask to a prepared ice-water bath for rapid cooling , causing it to stop reacting.

[0028] 3) Centrifuge the prepared solution at 12000 rpm for 10 min, discard the supernatant, disperse the obtained precipitate in about 3 ml of toluene, and then add acetonitrile (generally 600 μl) according to the ratio of tol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com