Compressor oil and preparation method and application thereof

A technology for compressor oil and base oil, applied in the field of hydraulic grease, can solve the problems of short oil change cycle, large amount of waste oil, inability to guarantee long-term and stable operation of air compressors, etc., and achieves easy operation, simple process flow and low cost controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] According to one aspect of the present invention, a kind of preparation method of above-mentioned compressor oil, described preparation method comprises the following steps:

[0096] (a), mixing phenolic antioxidants, amine antioxidants, metal deactivators, rust inhibitors and defoamers to prepare antioxidant additives;

[0097] (b), mixing long-chain synthetic hydrocarbons, polyol esters, benzoate compounds and benzene ring-containing synthetic hydrocarbons to obtain base oil;

[0098] (c), the base oil obtained in step (b) is dehydrated, then mixed with the antioxidant additive obtained in step (a) to obtain air compressor oil;

[0099] The order of step (a) and step (b) can be reversed.

[0100] The preparation method of compressor oil provided by the present invention, described preparation method is to make antioxidant additive by mixing phenolic antioxidant, amine antioxidant, metal deactivator, antirust agent and defoamer; Simultaneously Long-chain synthetic hy...

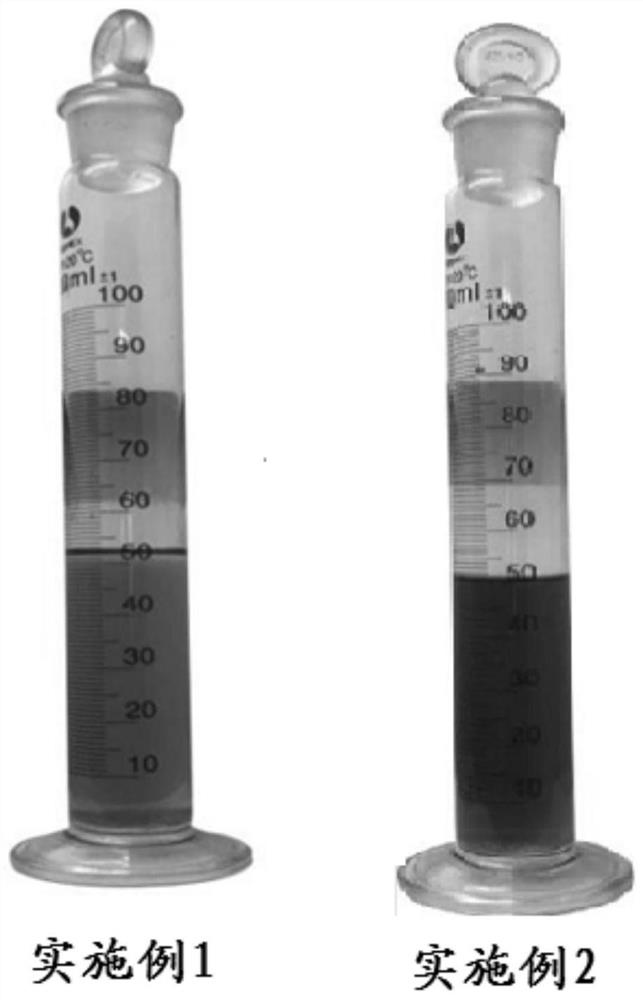

Embodiment 1

[0113] A kind of compressor oil, the preparation method of described compressor oil comprises the following steps:

[0114] (1) Add 48.098kg polyalphaolefin (SpectroSyn10, ExxxoMobil), 20kg polyol ester (Pr.3970, Croda), 20kg trimellitate (Pr.1942, Croda) and 10kg alkylnaphthalene to the mixing kettle (Synesstic AN5, ExxonMobil), mixed and stirred to obtain base oil;

[0115] (2) Under a nitrogen atmosphere, heat the base oil to 100°C, vacuum -0.07Mpa, and dehydrate for 1 hour. When the water content in the base oil is detected to be lower than 100ppm, cool the base oil to 70°C to obtain the dehydrated base oil;

[0116] (3) In the above base oil, add phenolic antioxidant L135 (BASF) 0.5kg, L115 (BASF) 0.3kg; amine antioxidant V81 (RT Vanderbilt) 0.4kg, IRGANOX L06 (BASF) 0.6kg Auxiliary antioxidant Irgamet39 (BASF) 0.05kg; Rust inhibitor IrgacorL12 (BASF) 0.05kg; Non-silicon defoamer Synative AC AMH2 0.002kg, stirred evenly, filtered to obtain compressor oil.

Embodiment 2

[0118] This example is the same as Example 1 except that the amine antioxidant IRGANOX L06 (BASF) is not included.

[0119] This example does not contain the amine antioxidant IRGANOX L06 (BASF). IRGANOX L06 (BASF) is an ashless high-temperature antioxidant, which has a low tendency to form sludge and effectively controls the increase in viscosity of air compressor oil due to oxidation. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com