High-sensitivity optical fiber photoacoustic gas detection system and method

A photoacoustic gas and high-sensitivity technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze fluids, measuring devices, and processing detection response signals. It can solve problems such as small gas production volume, sensitivity, and difficulty in improving signal-to-noise ratios Avoid poor stability, reduce the volume of the air chamber, and increase the effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

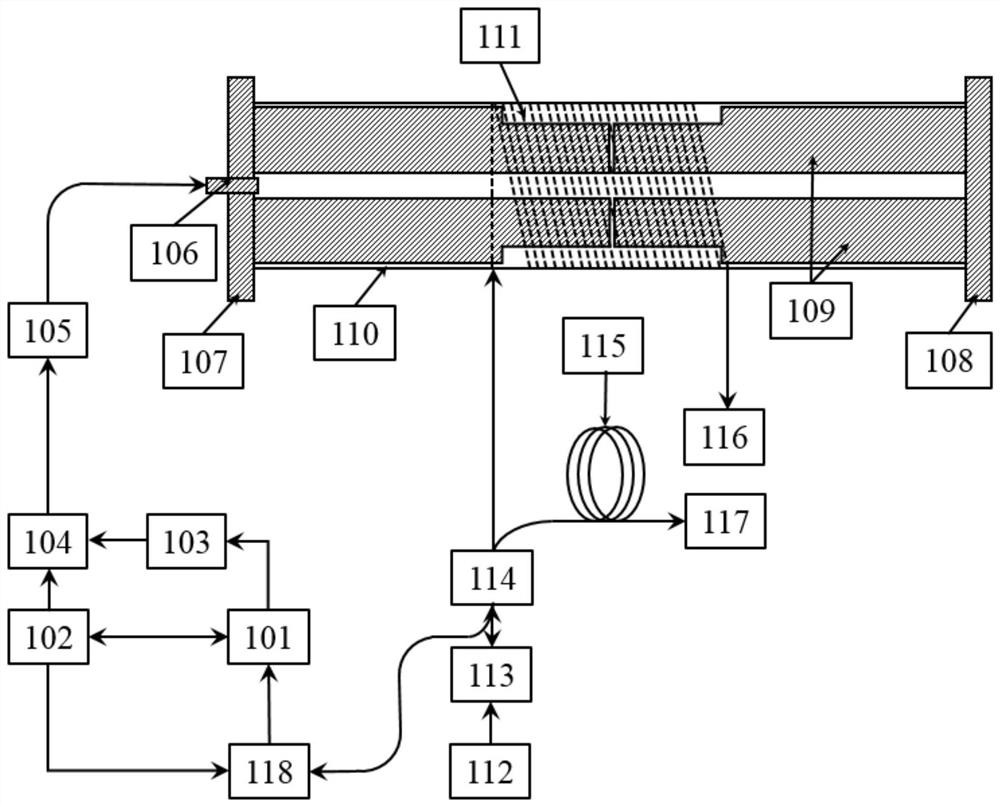

[0031] A fiber optic photoacoustic gas sensing system based on a hollow elastic tube, including a computer 101, a signal processing circuit 102, a digital signal generator 103, an adder 104, a DFB laser 105, an optical fiber collimator 106, and a 1# plane mirror 107, 2# plane mirror 108, photoacoustic cavity 109, hollow elastic tube 110, single-mode sensing fiber 111, ASE light source 112, fiber isolator 113, 2×2 fiber coupler 114, reference fiber 115, 1# Faraday Rotating mirror 116, 2# Faraday rotating mirror 117, spectrometer 118. The computer 101 controls the signal processing circuit 102 to output a sinusoidal modulation signal, and at the same time controls the digital signal generator 103 to output a sawtooth wave signal. After the two signals pass through the adder 104, the DFB laser and its driving circuit 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com