Application of triazine-carbazole polymer in organic electrode material

An organic electrode and polymer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limiting the application of organic electrode materials and reducing the cycle stability of potassium ion batteries, and achieve the effect of improving cycle stability and avoiding dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

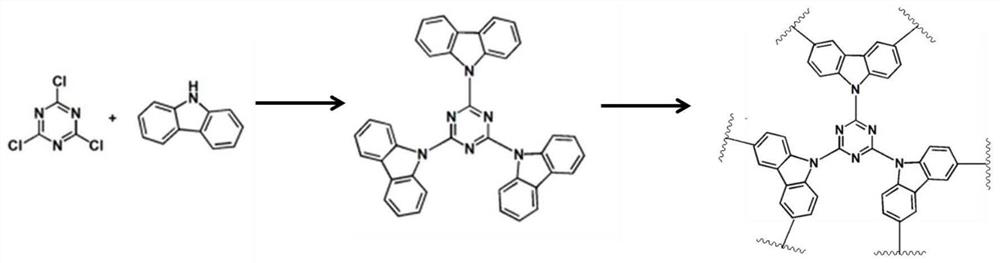

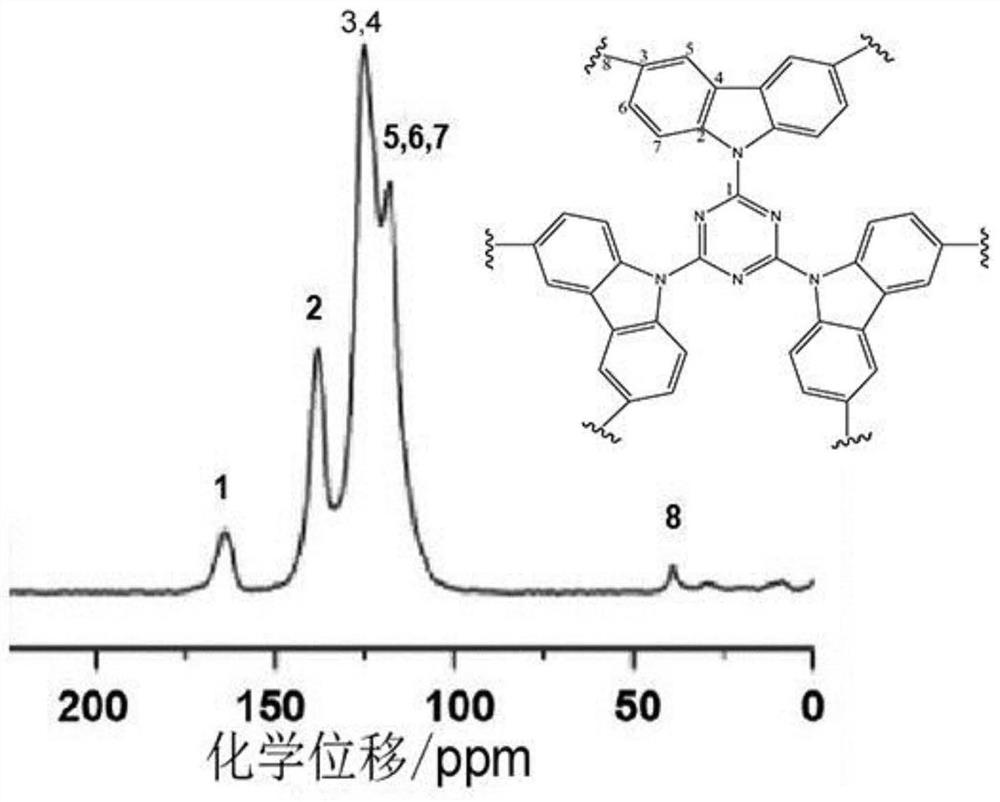

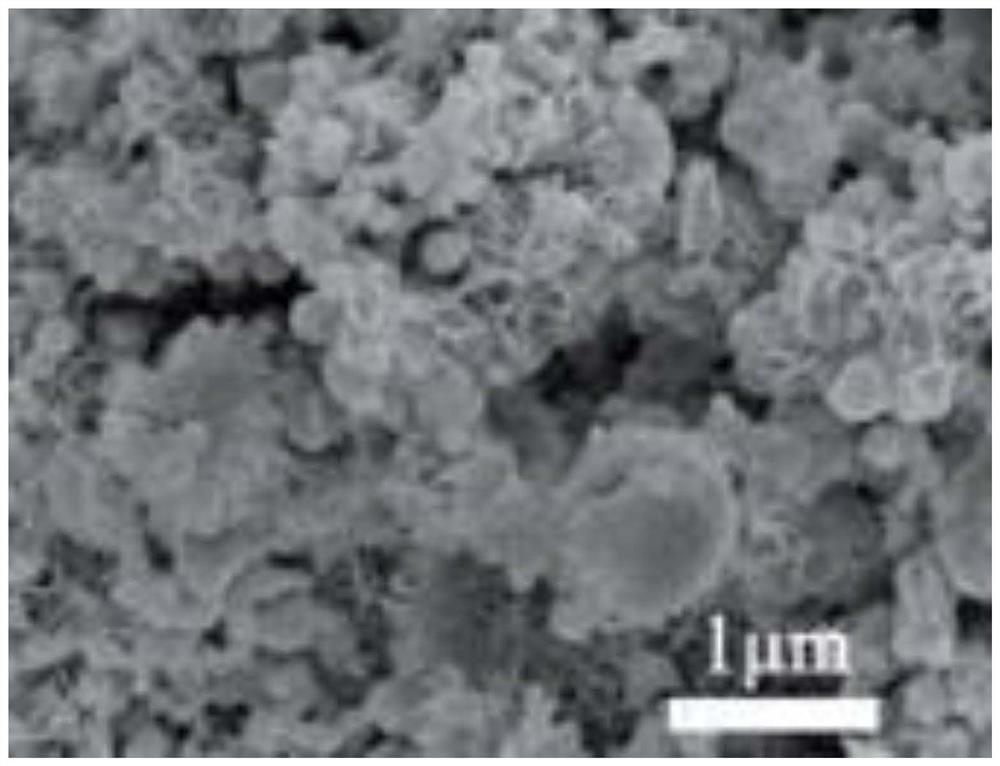

Method used

Image

Examples

Embodiment 1

[0030] This embodiment is the application of triazine-carbazole polymer as the negative electrode material of potassium ion battery, specifically:

[0031] A triazine-carbazole polymer is used as an active material, and a conductive agent and a binder are used to form a working electrode, and then a CR2032 button battery is formed with a counter electrode, a separator, and an electrolyte. The counter electrode is metal potassium, the separator is glass fiber (Whatman, Grade GF / D), and the electrolyte is KPF 6 Solution (KPF 6 The concentration is 0.8mol / L, and the solvent is a mixed solution of EC and DEC with a volume ratio of 1:1).

[0032] The working electrode is specifically prepared by the following method: mix triazine-carbazole polymer, conductive carbon black / multi-walled carbon nanotubes / single-walled carbon nanotubes, and polyvinylpyrrolidone in a mass ratio of 7:2:1, and the conductive The mass ratio of carbon black, multi-walled carbon nanotubes and single-walled...

Embodiment 2

[0038] The trimer-carbazole polymer of the present embodiment is also used as the negative electrode material of the potassium ion battery, which is basically the same as that of Example 1, the only difference being that the preparation process of the trimer-carbazole polymer is slightly different, and the trimer-carbazole polymer of the present embodiment -The concrete preparation process of carbazole polymer is:

[0039] (1) Under a nitrogen atmosphere, dissolve carbazole in tetrahydrofuran to prepare a solution containing carbazole with a molar concentration of 0.7mol / L; then, under cold bath conditions (the temperature of the cold bath is 0°C), add The n-hexane solution containing n-butyllithium (the molar concentration of n-butyllithium is 1.5mol / L), after the dropwise addition is completed (the molar ratio of carbazole and n-butyllithium is 1:1), continue to stir for 30min, and then remove Take a cold bath and return to room temperature to obtain a lithium salt solution ...

Embodiment 3

[0043] The trimer-carbazole polymer of the present embodiment is also used as the negative electrode material of the potassium ion battery, which is basically the same as that of Example 1, the only difference being that the preparation process of the trimer-carbazole polymer is slightly different, and the trimer-carbazole polymer of the present embodiment -The concrete preparation process of carbazole polymer is:

[0044] (1) Under a nitrogen atmosphere, dissolve carbazole in tetrahydrofuran to prepare a carbazole-containing solution with a molar concentration of 1mol / L; then add The n-hexane solution containing n-butyllithium (the molar concentration of n-butyllithium is 2.0mol / L), after the dropwise addition is completed (the molar ratio of carbazole and n-butyllithium is 1:1), continue to stir for 30min, and then remove Take a cold bath and return to room temperature to obtain a lithium salt solution of carbazole;

[0045] (2) Add the lithium salt solution of carbazole dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com