Application of collagen for producing frozen green body flour product

A collagen and flour product technology, applied in the application, food freezing, food coating and other directions, can solve the problems of destroying the protein structure of the dough, reducing the water holding capacity of the product, and having a bad taste of the product, shortening the fermentation time, improving the freezing Melt stability, the effect of reducing moisture loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

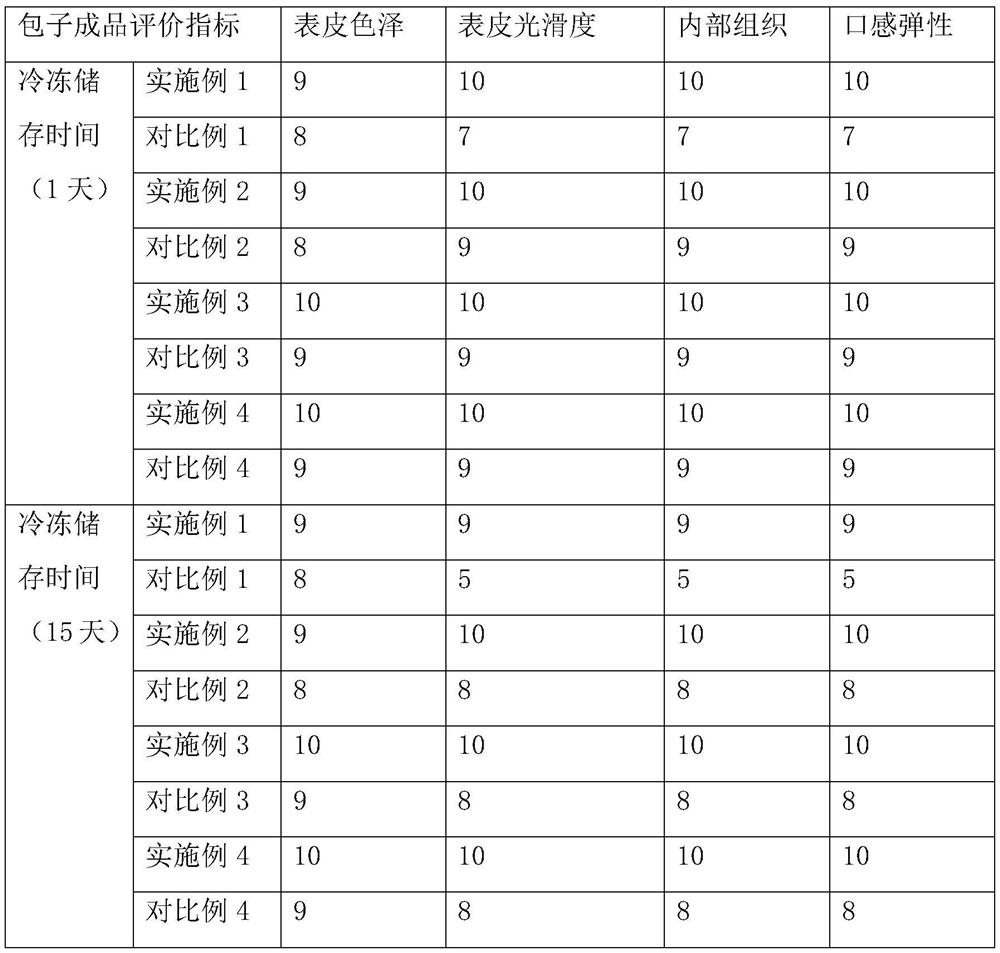

Embodiment 1

[0051] The application of a preferred collagen of the present invention in frozen green buns is prepared through the following formulas and steps.

[0052] The present embodiment prepares the frozen green buns with added collagen, including the following steps:

[0053] (1) Weigh 1000g of wheat flour, 10g of fresh yeast, 12g of collagen, 8g of sugar, 4g of salt, 10g of lard, and 450g of water, respectively.

[0054](2) Add fresh yeast, white sugar and salt to the water according to the stated proportions, stir and dissolve, and the water temperature is 4°C.

[0055] (3) mixing collagen and wheat flour, pouring into the mixed solution obtained in step (1), placing it in a dough mixer, stirring at low speed for 3 minutes, adding lard and stirring at high speed for 5 minutes, and kneading into dough;

[0056] (4) After pressing the dough for 9 times with a noodle pressing machine, it is formed with a bun machine, and the temperature of the filling used in forming is 20°C.

[00...

Embodiment 2

[0065] The application of a preferred collagen of the present invention in frozen green buns is prepared through the following formulas and steps.

[0066] The present embodiment prepares a collagen-added frozen green body improver and a steamed bun made with the frozen green body improver, including the following steps:

[0067] (1) respectively take by weighing wheat flour 1000g, fresh yeast 10g, sugar 8g, salt 4g, lard 10g, frozen green body improver 10g, water 450g; wherein, the frozen green body improver formula is as follows (the following is the mass fraction percentage): Xylanase 0.1%, a-amylase 0.1%, lipase 0.1%, vitamin C 0.5%, collagen 60%, soybean flour 15%, starch 24.2%.

[0068] (2) Add fresh yeast, white sugar and salt to the water according to the stated proportions, stir and dissolve, and the water temperature is 4°C.

[0069] (3) mixing the frozen green body improver and wheat flour, pouring into the mixed solution obtained in step (1), placing it in a dough...

Embodiment 3

[0079] The application of a preferred collagen of the present invention in frozen green buns is prepared through the following formulas and steps.

[0080] The present embodiment prepares a collagen-added frozen green body improver and a steamed bun made with the frozen green body improver, including the following steps:

[0081] (1) respectively take by weighing wheat flour 1000g, fresh yeast 10g, white sugar 8g, salt 4g, lard 10g, frozen green body improver 10g, water 480g; wherein, the frozen green body improver formula is as follows (the following is the mass fraction percentage): Xylanase 0.1%, Glucoamylase 0.1%, α-Amylase 0.1%, Lipase 0.1%, Vitamin C 0.5%, Guar Gum 3%, Sodium Alginate 3%, Collagen 50%, Soybean Powder 15%, starch 28.1%.

[0082] (2) Add fresh yeast, white sugar and salt to the water according to the stated proportions, stir and dissolve, and the water temperature is 4°C.

[0083] (3) mixing the frozen green body improver and wheat flour, pouring into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com