TiN/C coated lithium tritium orthosilicate breeding agent and preparation method and preparation device system thereof

A tritium breeding agent and coating device technology, applied in the field of nuclear fusion, can solve problems such as low heat transfer, fragility, and cladding material corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

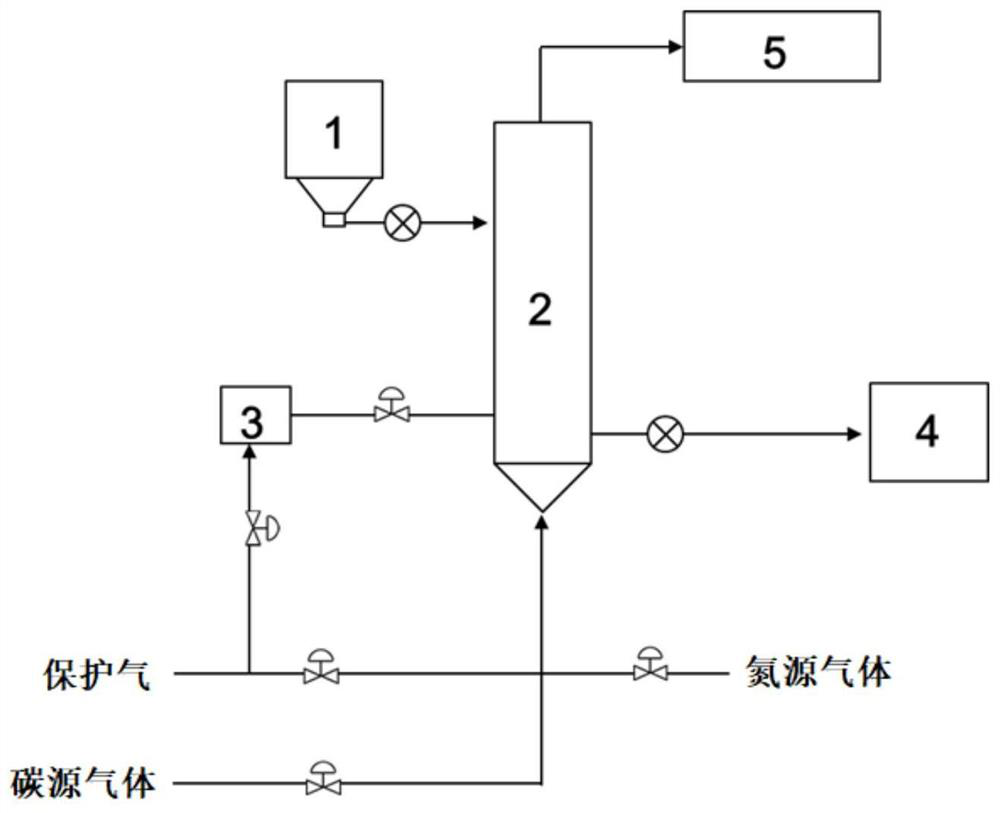

[0064] This embodiment provides a TiN / C coated Li 4 SiO 4 The preparation method of tritium multiplying agent, described preparation method provided in the present invention such as figure 1 Carry out in the shown device system, described preparation method comprises the following steps:

[0065] (1) Spherical Li with a particle size of 0.6mm 4 SiO 4 The particles are in a fluidized state in the protective atmosphere of argon;

[0066] (2) On the basis of continuing in step (1), pass carbon source gas methane into Li 4 SiO 4 In the protective atmosphere where the particles are located, the C-coated Li 4 SiO 4 Particles; the mixing temperature is 700°C, and the mixing time is 30 minutes; the gas flow rate of the carbon source gas is 125mL / min;

[0067] (3) On the basis of continuing the step (1), the titanium source gas and the nitrogen source gas are independently fed into the C-coated Li 4 SiO 4 In the protective atmosphere where the particles are located, the mixin...

Embodiment 2

[0072] This embodiment provides a TiN / C coated Li 4 SiO 4 The preparation method of tritium multiplying agent, described preparation method provided in the present invention such as figure 1 Carry out in the shown device system, described preparation method comprises the following steps:

[0073] (1) Make spherical Li with an average particle size of 0.9mm 4 SiO 4 Particles are in a fluidized state in a protective atmosphere of helium;

[0074] (2) On the basis of continuing in step (1), pass carbon source gas ethane into Li 4 SiO 4 In the protective atmosphere where the particles are located, the C-coated Li 4 SiO 4 Particles; the mixing temperature is 800°C, and the mixing time is 45 minutes; the gas flow rate of the carbon source gas is 160mL / min;

[0075] (3) On the basis of continuing the step (1), the titanium source gas and the nitrogen source gas are independently fed into the C-coated Li 4 SiO 4 In the protective atmosphere where the particles are located, t...

Embodiment 3

[0079] This embodiment provides a TiN / C coated Li 4 SiO 4 The preparation method of tritium multiplying agent, described preparation method provided in the present invention such as figure 1 Carry out in the shown device system, described preparation method comprises the following steps:

[0080] (1) Spherical Li with a particle size of 0.3mm 4 SiO 4 The particles are in a fluidized state in a protective atmosphere of neon;

[0081] (2) On the basis of continuing in step (1), pass carbon source gas ethylene into Li 4 SiO 4 In the protective atmosphere where the particles are located, the C-coated Li 4 SiO 4 Particles; the mixing temperature is 600°C, and the mixing time is 15 minutes; the gas flow rate of the carbon source gas is 85mL / min;

[0082] (3) On the basis of continuing the step (1), the titanium source gas and the nitrogen source gas are independently fed into the C-coated Li 4 SiO 4 In the protective atmosphere where the particles are located, the mixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com