Comprehensive treatment device and treatment method for acetone wastewater and organic halide wastewater

A technology for comprehensive treatment of organic halogenated substances, which is applied in the field of comprehensive treatment devices for acetone wastewater and organic halogenated wastewater. It can solve the problems of low molecular sieve strength, easy breakage, no industrialized treatment methods, and large regeneration energy consumption, etc., and achieve economic benefits. Significant, good application prospects, large processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Comprehensive treatment device and treatment method for acetone wastewater and organic halogenated wastewater

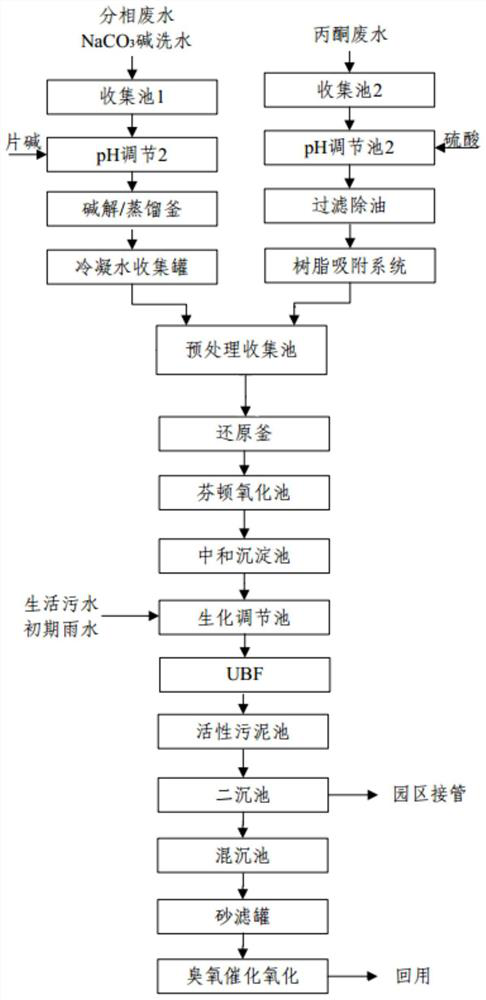

[0051] Such as figure 1 As shown, the steps of treating fungicide wastewater are as follows:

[0052] (1) The phase separation / alkali washing water enters the collection pool 1, adjusts the pH=11.5 in the pH adjustment pool (tank), carries out the alkaline hydrolysis reaction at a constant temperature of 60°C for 3 hours, conducts evaporation and desalination treatment after the alkaline hydrolysis, and collects the condensed water in the workshop Tank, pumped into the sewage station pretreatment collection pool;

[0053] (2) Acetone wastewater enters the collection pool 2, adjusts pH=3.5 in the pH adjustment pool (tank), removes oily substances in the turbid wastewater through the filtration system, and the effluent enters the resin adsorption system, and the effluent is collected and transported to the sewage through pipelines Station pretreatment collecti...

Embodiment 2

[0062] Comprehensive treatment device and treatment method for acetone wastewater and organic halogenated wastewater

[0063] Such as figure 1 Shown, in the present embodiment, the step that fungicide waste water is processed is as follows:

[0064] (1) The phase separation / alkali washing water enters the collection pool 1, adjusts the pH=11.1 in the pH adjustment pool (tank), carries out the alkaline hydrolysis reaction at a constant temperature of 60°C for 3 hours, and conducts evaporation and desalination treatment after the alkaline hydrolysis, and the condensed water enters the workshop for collection Tank, pumped into the sewage station pretreatment collection pool;

[0065] (2) The acetone wastewater enters the collection pool 2, adjusts the pH=3.9 in the pH adjustment pool (tank), removes the oily substances in the turbid wastewater through the filtration system, and the effluent enters the resin adsorption system. After the adsorption effluent is collected, it is tra...

Embodiment 3

[0075] Comprehensive treatment device and treatment method for acetone wastewater and organic halogenated wastewater

[0076] Such as figure 1 Shown, in the present embodiment, the step that fungicide waste water is processed is as follows:

[0077] (1) The phase separation / alkali washing water enters the collection pool 1, adjusts the pH=11.2 in the pH adjustment pool (tank), carries out the alkaline hydrolysis reaction at a constant temperature of 60°C for 3 hours, conducts evaporation and desalination treatment after the alkaline hydrolysis, and collects the condensed water in the workshop Tank, pumped into the sewage station pretreatment collection pool;

[0078] (2) Acetone wastewater enters the collection pool 2, adjusts pH=3.1 in the pH adjustment pool (tank), removes oily substances in the turbid wastewater through the filtration system, and the effluent enters the resin adsorption system, and the effluent is collected and transported to the sewage through pipelines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com