Orthodontic correction composite material and preparation method thereof

A composite material and orthodontic technology, applied in the field of medical materials, can solve the problems of insufficient elastic recovery force in mechanical properties, insufficient stress teeth, insufficient orthodontic force, etc., to achieve excellent stability, excellent performance, and good display effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

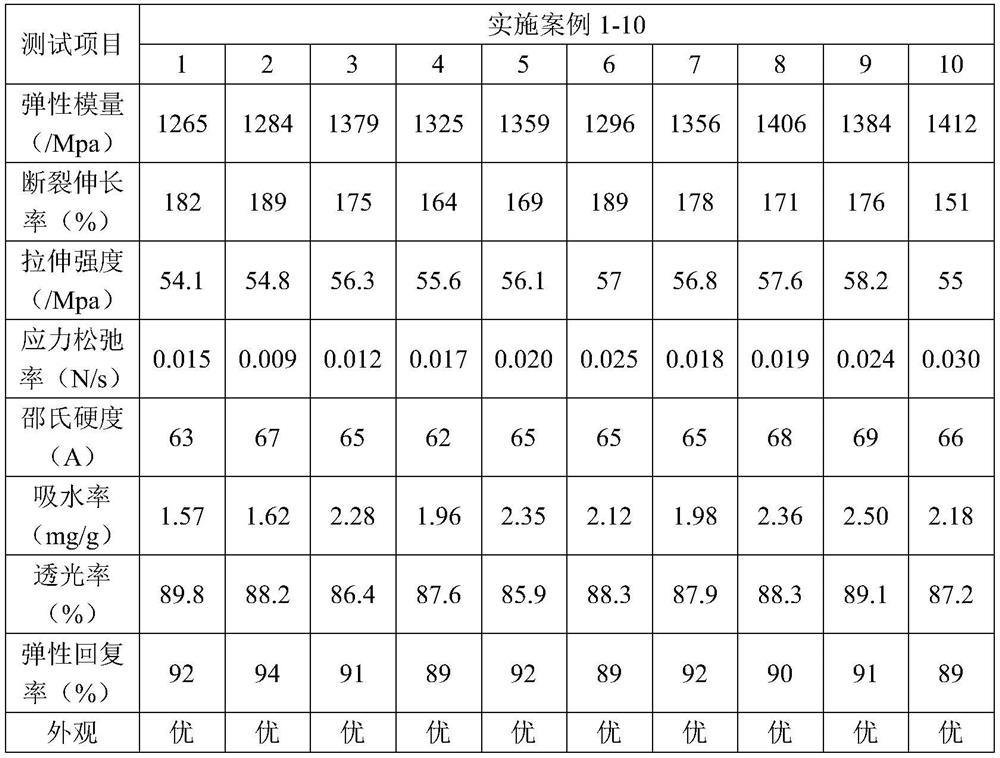

Examples

Embodiment 1-10

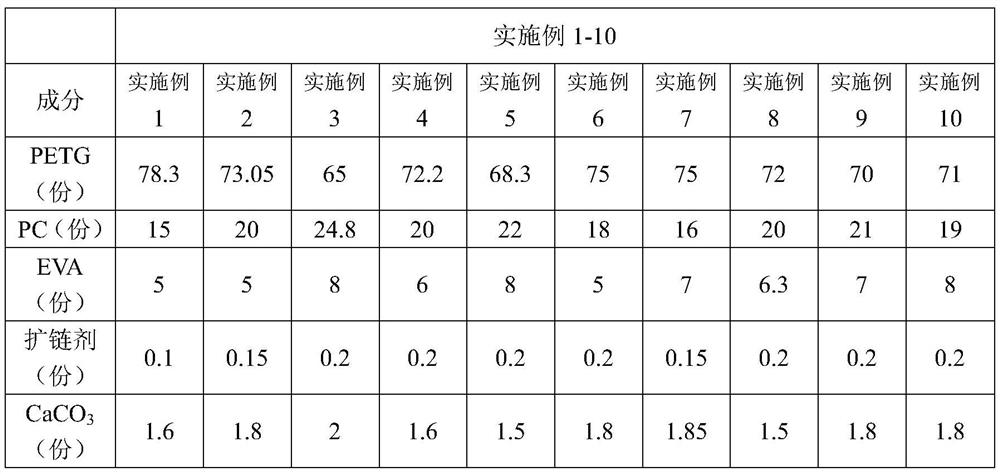

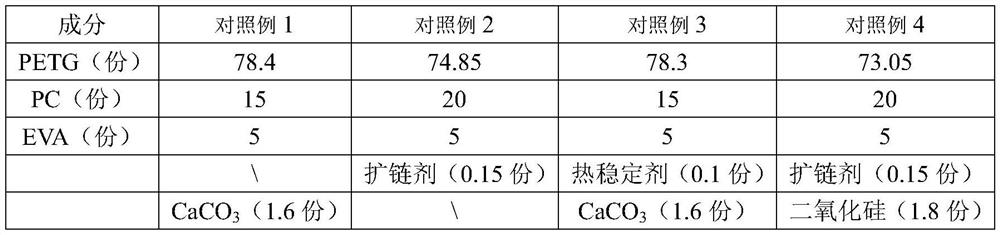

[0072] The components and contents are as follows:

[0073]

[0074] in,

Embodiment 1-3

[0075] The preparation method of embodiment 1-3 is as follows:

[0076] 1) All raw materials are dried and pretreated. The drying temperature of PETG, polycarbonate and ethylene vinyl acetate copolymer is 70°C, the drying temperature of chain extender and light calcium carbonate is 45°C, and dry for 7 hours;

[0077] 2) Select surface-treated light calcium carbonate, chain extender and ethylene vinyl acetate copolymer for melt blending and granulation;

[0078] 3) blending and melting the granules obtained in step 2) and polycarbonate together;

[0079] 4) melt blending and granulating polyethylene terephthalate-1,4-cyclohexanedimethanol and the pellets obtained in step 3);

[0080] 5) Melting and granulating the pellets in step 4) again to obtain a composite material for orthodontic correction.

[0081] In steps 2), 3), 4) and 5), the melt extrusion process adopts a twin-screw extruder to extrude.

[0082] The twin-screw extruder is the KET-20 twin-screw extruder of Nanjin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com