TPV easy to bond with glue and manufacturing method thereof

A technology of glue and maleic anhydride, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of TPV being difficult to glue water, etc., to improve the performance of glue water and improve the quality of materials Polarity and surface energy, effect of improving wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

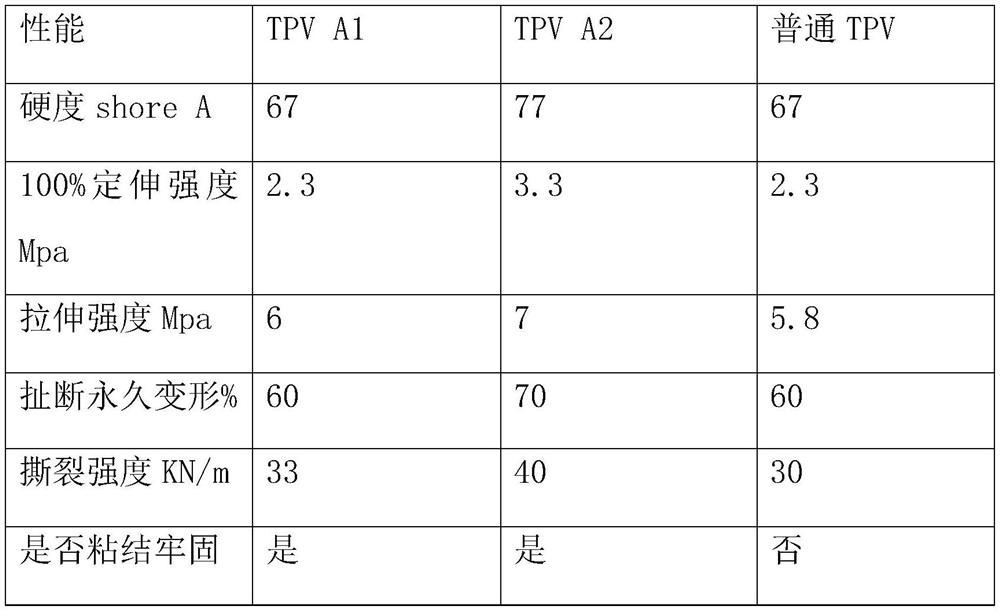

Examples

Embodiment 1

[0035] 40-50 parts of EPDM, 30-40 parts of naphthenic oil, 20-25 parts of PP (polypropylene), 5-6 parts of EMMA, 10-15 parts of calcium carbonate, 0.5 parts of DCP, 1 part of TAIC, 0.3 parts of antioxidant .

[0036] 1. After weighing EPDM, PP, grafted PP and calcium carbonate on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidants at the same time, and stir for 3 minutes.

[0037] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 190°C, and granulate to form a premix.

[0038] 3. Add the cross-linking agent DCP and auxiliary cross-linking agent TAIC and the premix weighed according to the above formula into a high-speed stirring pot at 500-600 rpm, and mix for 3 minutes.

[0039] 4. Add the mixture obtained in 3 into a twin-screw extruder with an aspect ratio of 52 for granulation. The rotation speed is 220rpm...

Embodiment 2

[0042] 40-50 parts of EPDM, 20-30 parts of naphthenic oil, 30-35 parts of PP (polypropylene), 6-8 parts of EMMA, 0.5 parts of BIPB, 1 part of TMPTMA, and 0.3 parts of antioxidant.

[0043] 1. After weighing EPDM, PP, grafted PP and calcium carbonate on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidants at the same time, and stir for 3 minutes.

[0044] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 190°C, and granulate to form a premix.

[0045] 3. Add the cross-linking agent DCP and auxiliary cross-linking agent TAIC and the premix weighed according to the above formula into a high-speed stirring pot at 500-600 rpm, and mix for 3 minutes.

[0046] 4. Add the mixture obtained in 3 into a twin-screw extruder with an aspect ratio of 52 for granulation. The rotation speed is 220rpm, and the plasticizing temper...

Embodiment 3

[0048] Embodiment three (common TPV, comparison sample):

[0049] 40-50 parts of EPDM, 30-40 parts of white oil, 20-25 parts of PP (polypropylene), 0.5 parts of lubricant, 0.5 parts of DCP, 1 part of TAIC, and 0.3 parts of antioxidant.

[0050] 1. After weighing EPDM and PP on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidant and lubricant at the same time, and stir for 3 minutes.

[0051] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 190°C, and granulate to form a premix.

[0052] 3. Add the cross-linking agent DCP and auxiliary cross-linking agent TAIC weighed according to the above formula into the high-speed stirring pot at a speed of 500-600 rpm, and mix for 3 minutes.

[0053]4. Add the mixture obtained in 3 into a twin-screw extruder with an aspect ratio of 52 for granulation. The rotation speed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com