Degradable polyester fiber and preparation method thereof

A technology for degrading polyester and fiber, applied in the field of polyester fiber materials, can solve the problems of poor stability of PET materials, complex processing technology, secondary pollution, etc., and achieve the effects of promoting degradation rate, increasing degradation rate, and accelerating aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

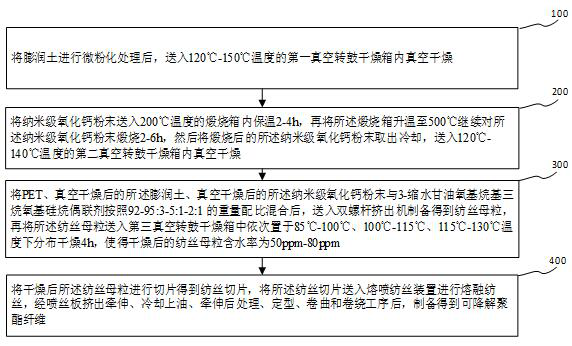

[0026] figure 1 It is a method flowchart of a preparation method of a degradable polyester fiber shown according to an exemplary embodiment, in figure 1 Among them, the preparation method of the degradable polyester fiber includes:

[0027] Step 100: after the bentonite is micronized, it is sent to a first vacuum drum drying oven at a temperature of 120° C.-150° C. for vacuum drying.

[0028] Step 200: put the nano-scale calcium oxide powder into a calcination box at 200°C for 2-4 hours, then raise the temperature of the calcination box to 500°C to continue calcination of the nano-scale calcium oxide powder for 2-6 hours, and then place the calcination The final nano-scale calcium oxide powder is taken out and cooled, and sent to a second vacuum drum drying oven at a temperature of 120° C.-140° C. for vacuum drying.

[0029] Step 300: Combine PET, vacuum-dried bentonite, vacuum-dried nanoscale calcium oxide powder and 3-glycidyloxyalkyltrialkoxysilane coupling agent accordin...

Embodiment 1

[0043] Step 1: After the bentonite is micronized, it is sent to the first vacuum drum drying oven at a temperature of 130° C. for vacuum drying, and the particle size of the bentonite material after the micronization is 300 nm.

[0044] Step 2: put the nano-scale calcium oxide powder into a calcination box at 200°C for 4 hours, then raise the temperature of the calcination box to 500°C and continue to calcine the nano-scale calcium oxide powder for 4 hours, and then place the calcined The nanoscale calcium oxide powder is taken out and cooled, and then sent to a second vacuum drum drying oven at a temperature of 120° C. for vacuum drying. The particle size of the nanoscale calcium oxide powder material is 60 nm.

[0045] Step 3: The PET, the vacuum-dried bentonite, the vacuum-dried nano-scale calcium oxide powder and the 3-glycidyloxyalkyltrialkoxysilane coupling agent according to the ratio of 95:3:1:1 After mixing the weight ratio, it is sent into the twin-screw extruder to ...

Embodiment 2

[0053] Step 1: After the bentonite is micronized, it is sent to the first vacuum drum drying oven at a temperature of 150° C. for vacuum drying, and the particle size of the bentonite material after the micronization is 200 nm.

[0054] Step 2: Put the nano-scale calcium oxide powder into a calcination box at 200°C for 3 hours, then raise the temperature of the calcination box to 500°C to continue calcining the nano-scale calcium oxide powder for 5 hours, and then place the calcined The nanoscale calcium oxide powder is taken out and cooled, and then sent to a second vacuum drum drying oven at a temperature of 130° C. for vacuum drying. The particle size of the nanoscale calcium oxide powder material is 50 nm.

[0055] Step 3: the PET, the vacuum-dried bentonite, the vacuum-dried nano-scale calcium oxide powder and the 3-glycidyloxyalkyltrialkoxysilane coupling agent according to the ratio of 94:4:1:1 After mixing the weight ratio, it is sent into the twin-screw extruder to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com