Graphite tank for sintering silicon carbide ceramic tube, high-performance silicon carbide ceramic tube and preparation method of high-performance silicon carbide ceramic tube

A technology of silicon carbide ceramics and graphite grooves, which is applied in the field of engineering ceramic materials, can solve problems such as difficulty in ensuring the straightness and roundness of pipes, and achieve the convenience of mass industrial production, excellent straightness and roundness, and short setting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

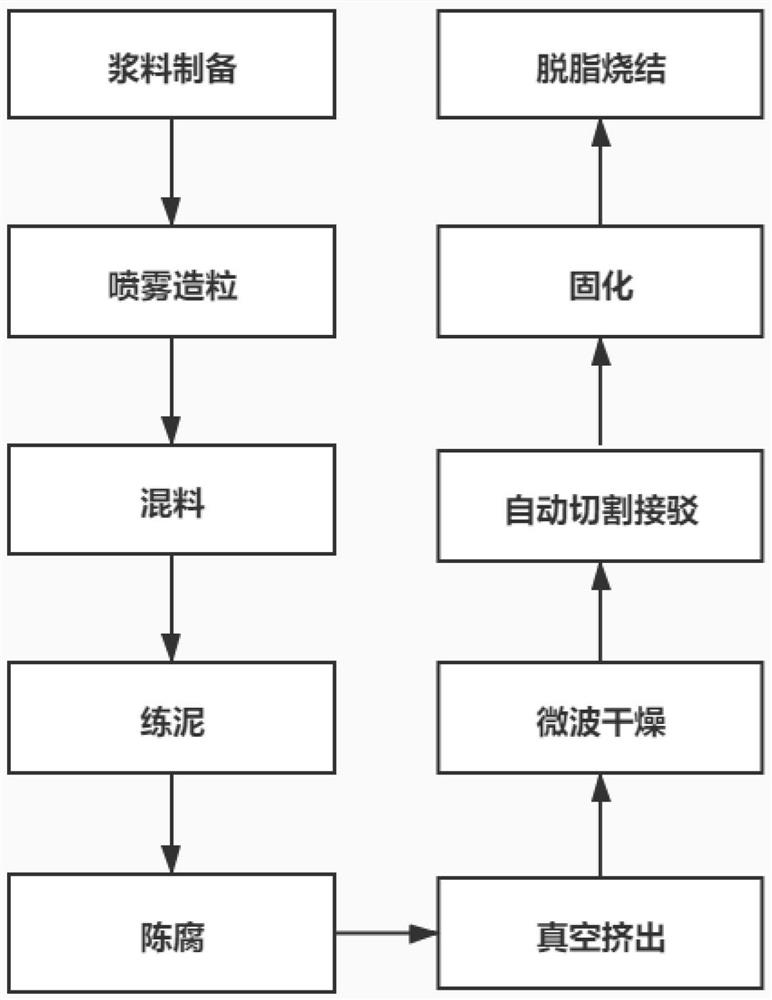

[0076] 1) Slurry preparation:

[0077] The main raw material is composed of the following components by weight: 99.5wt% submicron silicon carbide powder and 0.5wt% boron carbide;

[0078] Add 1.0wt% polyethylene glycol, 0.3wt% tetramethylammonium hydroxide, and 10.0wt% water-based phenolic resin into deionized water, and stir for 5 minutes to dissolve and disperse evenly to form an aqueous solution of organic additives. The total weight of deionized water is 125wt% of the silicon carbide powder;

[0079] The organic additive aqueous solution, submicron silicon carbide powder, and boron carbide are sequentially added into a sand mill, and there are 200wt% silicon carbide ceramic balls in the sand mill, and stirred evenly to form a silicon carbide slurry. Slurry ball milling time is 4h;

[0080] 2) Spray granulation:

[0081] The above slurry is subjected to spray granulation, wherein the inlet temperature is 220°C and the outlet temperature is 110°C;

[0082] 3) Mixing:

...

Embodiment 2

[0098] 1) Slurry preparation:

[0099] The main raw material is composed of the following components by weight: 99.7wt% submicron silicon carbide powder and 0.3wt% boron carbide;

[0100] Add 0.5wt% polyethylene glycol, 0.5wt% tetramethylammonium hydroxide, and 12.0wt% water-based phenolic resin into deionized water, and stir for 8 minutes to dissolve and disperse evenly to form an aqueous solution of organic additives. The total weight of deionized water is 110wt% of the silicon carbide powder;

[0101] The organic additive aqueous solution, submicron silicon carbide powder, and boron carbide are sequentially added into a sand mill, which contains 150 wt% silicon carbide ceramic balls, and stirred evenly to form a silicon carbide slurry. The slurry ball milling time is 2h.

[0102] 2) Spray granulation:

[0103] The above slurry is subjected to spray granulation, wherein the inlet temperature is 210°C and the outlet temperature is 100°C;

[0104] 3) Mixing:

[0105] The ...

Embodiment 3

[0119] After the obtained spray granulation powder is directly added into deionized water, it is smelted and stale. The rest are identical to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com