Preparation method of MOF/aramid nanofiber modified Nafion proton exchange membrane with beaded structure for fuel cell

A technology of nanofibers and fuel cells, applied in fuel cells, circuits, electrical components, etc., can solve the problems of lack of performance and poor interfacial compatibility of nanofiber composite proton exchange membranes, and reduce swelling and methanol penetration Sex, improve water retention capacity, good proton conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

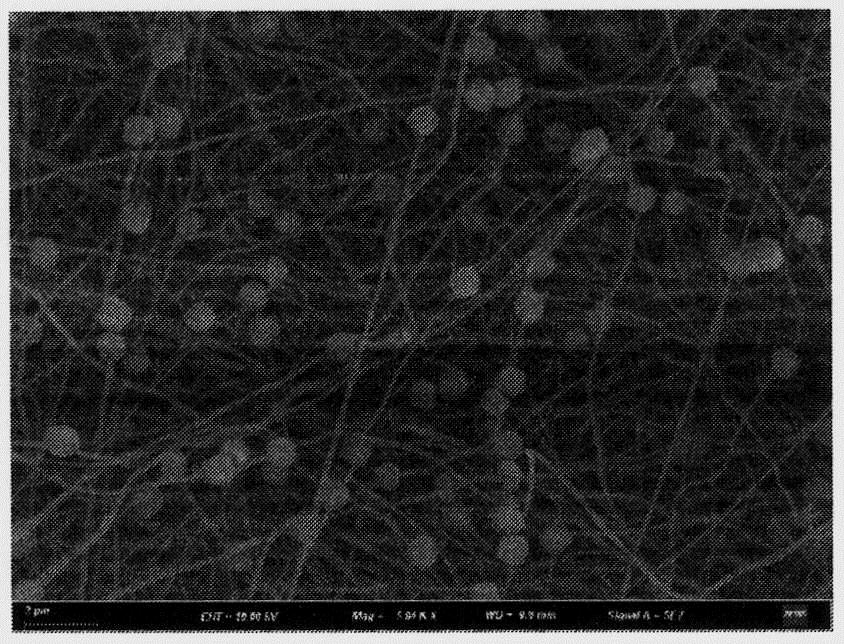

[0026] Dissolve the aramid stock solution in N,N-dimethylacetamide and stir evenly, then add 2% tetrabutylammonium chloride to the mixed solution to prepare a 58wt% spinning solution, and then mix the formed The solution was stirred at high speed for 6 hours at room temperature to form a uniform and stable spinning solution. It is spun on a receiving roller by electrospinning, and the spinning voltage and receiving distance are 30kv and 17cm, respectively. An aramid nanofiber membrane with a thickness of 80 μm was prepared.

[0027] Soak the aramid nanofiber membrane in the cobalt nitrate aqueous solution for 12 hours, and then stir and mix it with the 2-methylimidazole aqueous solution, wherein the molar ratio of cobalt nitrate, 2-methylimidazole and water is 1:20:2228, and the solution turns purple After that, let it stand for 12 hours. The composite membrane was repeatedly washed with distilled water, and finally placed in a vacuum oven to dry at 60° C. to obtain a beaded...

Embodiment 2

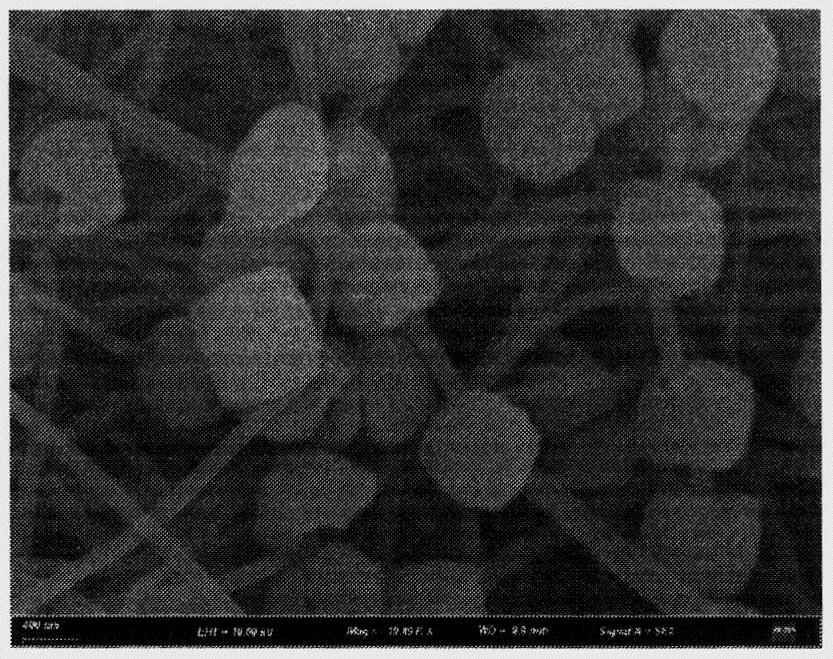

[0030] Dissolve the aramid stock solution in N,N-dimethylacetamide and stir evenly, then add 3% tetrabutylammonium chloride to the mixed solution to prepare a 58wt% spinning solution, and then mix the formed mixed solution Stir at high speed for 6 hours at room temperature to form a uniform and stable spinning solution. It is spun on a receiving roll by electrospinning, and the spinning voltage and receiving distance are 31kv and 17cm, respectively. An aramid nanofiber membrane with a thickness of 90 μm was prepared.

[0031] First, cobalt nitrate and 2-methylimidazole were dissolved in 20ml of methanol solution, and the aramid nanofiber membrane was soaked in cobalt nitrate methanol solution for 12 hours, and then stirred and mixed with 2-methylimidazole methanol solution, wherein cobalt nitrate, 2- The molar ratio of methylimidazole was 1:30. After the solution turned purple, it was allowed to stand for 12 hours. The composite membrane was repeatedly washed with methanol, ...

Embodiment 3

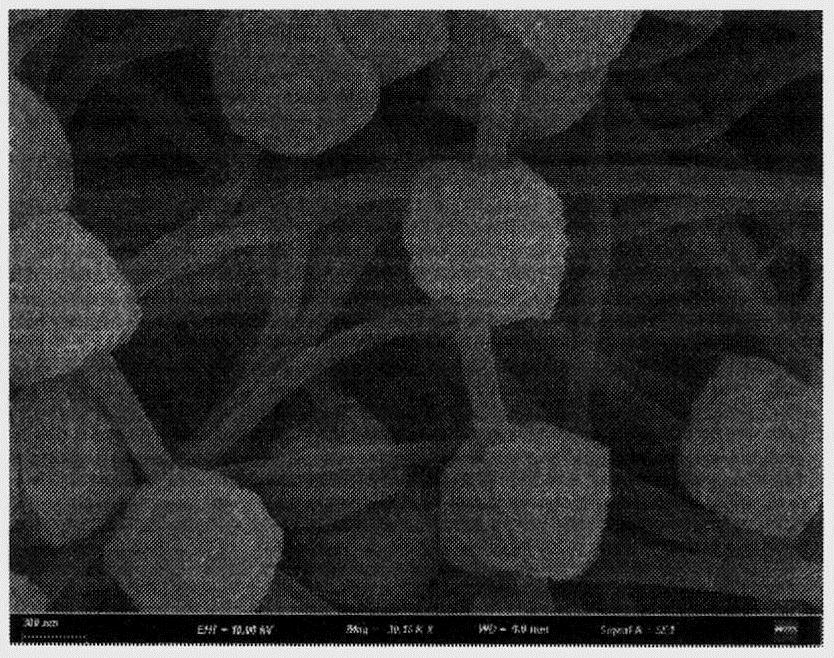

[0034]Dissolve the aramid stock solution in N,N-dimethylacetamide and stir evenly, then add 3% tetrabutylammonium chloride to the mixed solution to prepare a 58wt% spinning solution, and then mix the formed The solution was stirred at high speed for 6 hours at room temperature to form a uniform and stable spinning solution. It is spun on a receiving roll by electrospinning, and the spinning voltage and receiving distance are 31kv and 17cm, respectively. An aramid nanofiber membrane with a thickness of 90 μm was prepared.

[0035] First, cobalt chloride and 2-methylimidazole were dissolved in 20ml of methanol solution, and the aramid nanofiber membrane was soaked in cobalt chloride methanol solution for 12 hours, and then stirred and mixed with 2-methylimidazole methanol solution, in which cobalt chloride , The molar ratio of 2-methylimidazole is 1:40, after the solution turns purple, let it stand for 12h. Wash the composite membrane repeatedly with ethanol, and finally place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com