Near-infrared absorbing composition, near-infrared absorbing film, and image sensor for solid-state imaging element

A near-infrared, absorptive technology, applied in optical components, instruments, chemical instruments and methods, etc., can solve the dispersion stability of copper complexes (insufficient moisture resistance, no mention of near-infrared absorbing compositions) Stability, the impact of the final quality of the near-infrared blocking filter, etc., to achieve the effect of excellent near-infrared light absorption, visible light transmittance, and improved dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0402]"Preparation of Near Infrared Absorbent"

[0403](Preparation of Near Infrared Absorber 1)

[0404]The near-infrared absorber 1 was prepared according to the following method.

[0405]16.54 g of copper acetate and 661.46 g of tetrahydrofuran (abbreviation: THF) as a solvent were mixed, the copper acetate was dissolved using an ultrasonic irradiation machine, and the filtration operation was performed to remove the insoluble copper acetate to obtain 678 g of copper acetate solution.

[0406]Next, with respect to 678 g of the copper acetate solution, a solution prepared by dissolving 43.86 g of an exemplary compound (V-1) which is a compound represented by the general formula (V) in 80.0 g of THF was added while stirring for 30 minutes Next, after stirring at room temperature for 16 hours, 238.97g of toluene was added, and THF as a solvent was volatilized in an environment of 55-90°C for 3 hours to make the solid content 10% by mass, and 251.0g of near-infrared absorption was prepared.剂1.

[0...

Embodiment 2

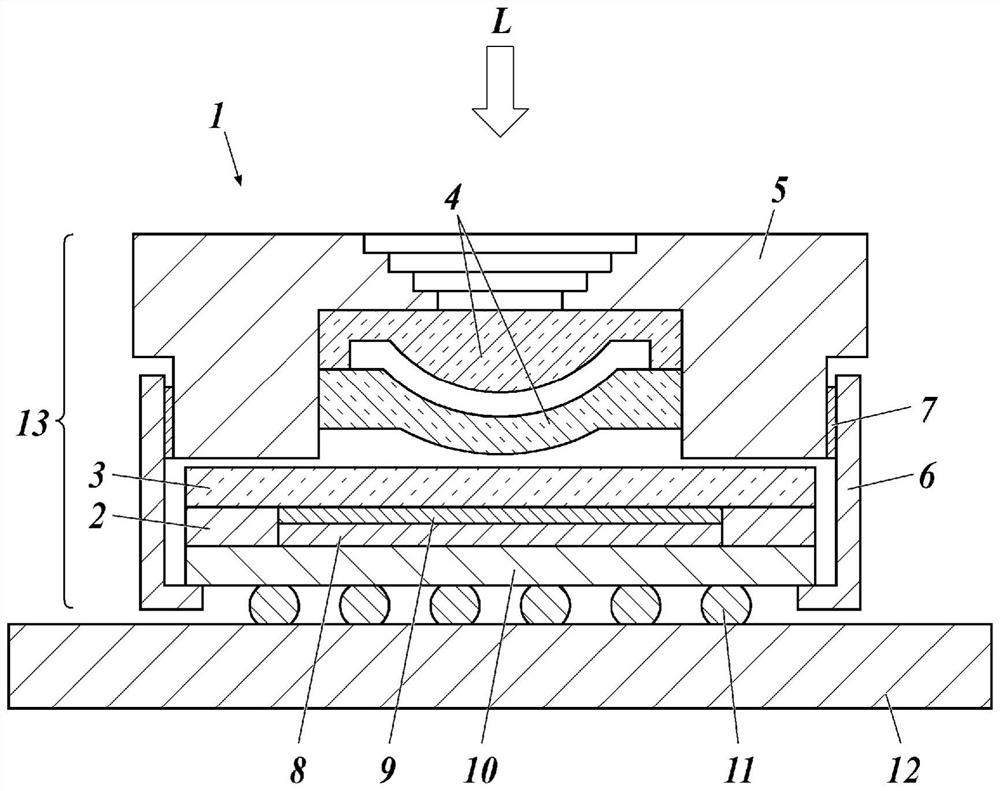

[0518]"Production of Near Infrared Absorbing Film"

[0519]To each near-infrared absorbing composition prepared in Example 1, a polysiloxane silicone resin (KR-255, manufactured by Shin-Etsu Chemical Co., Ltd.) was added and stirred to prepare a coating liquid for forming a near-infrared absorbing film . The prepared coating liquid was applied on the substrate by spin coating to produce near-infrared absorbing films 1 to 39.

[0520]Next, predetermined heat treatment was performed on the near-infrared absorbing film to cure the coating film, and near-infrared blocking filters 1 to 39 which can be applied to an image sensor for a solid-state imaging element were produced.

[0521]For each near-infrared cut-off filter produced above, the visible light transmittance and near-infrared transmittance in the film state were evaluated in the same manner as in the method described in Example 1. As a result, it was confirmed that the near-infrared cut-off filter system The same effect is also obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| carbon number | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com