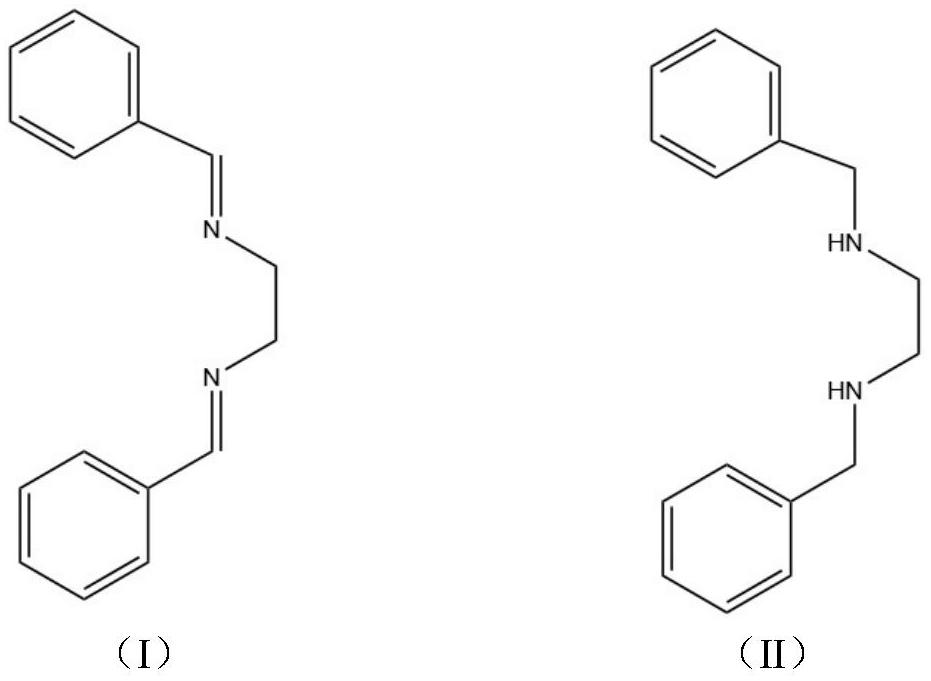

High-dispersion nitrogen-sulfur co-doped catalyst and preparation thereof, and application in synthesis of N,N-dibenzylethylenediamine

A dibenzylidene ethylenediamine, nitrogen and sulfur co-doping technology, applied in the direction of catalyst activation/preparation, preparation of amino compounds, preparation of organic compounds, etc., can solve the problem of difficult balance between activity and selectivity, easy polymerization reaction, etc. problem, to achieve the effect of more application times, inhibit hydrogenolysis reaction, and improve utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

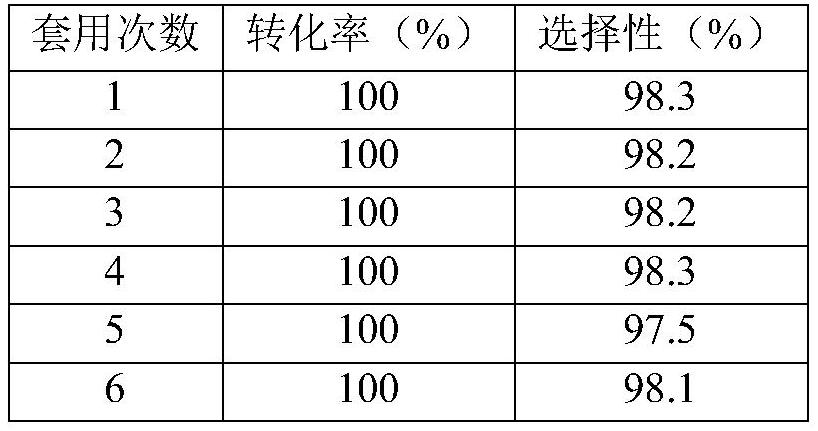

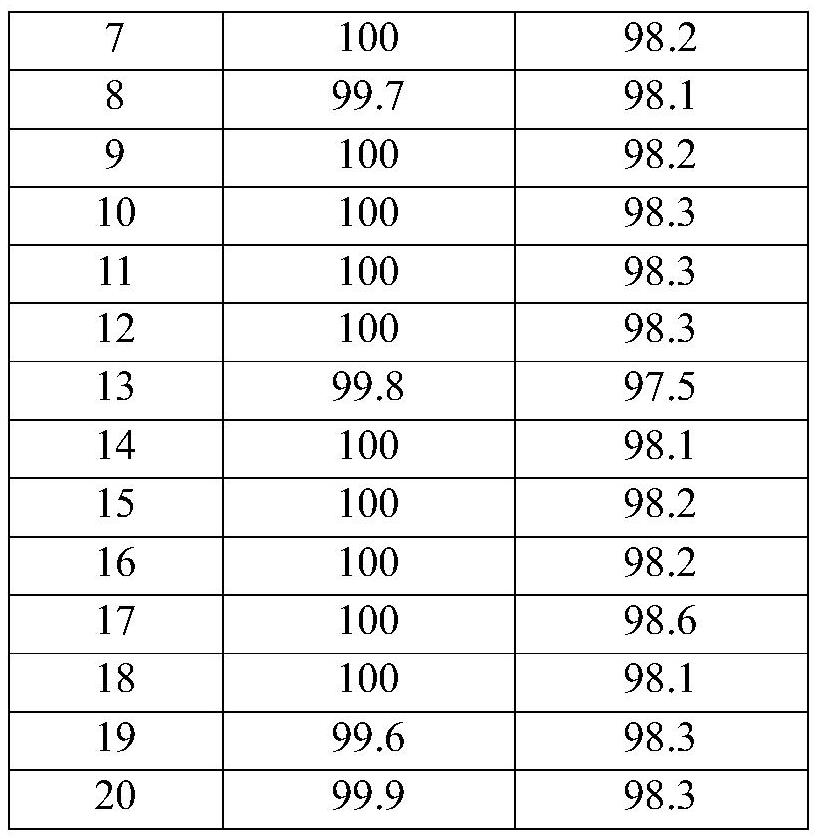

Embodiment 1

[0029] Weigh 50ml of 20wt% nitric acid solution, soak 6g of activated carbon in the nitric acid solution by slowly adding dropwise while stirring with a magnetic stirrer, and slowly heat to 80°C for 10h. After cooling to room temperature, wash with deionized water until the filtrate is neutral. Weigh 0.119g of thiourea solid, 5g of nitric acid-treated activated carbon, and mix with 30ml of deionized water. After mixing, they are ultrasonically treated at 40°C for 0.5h, and then vacuum-dried at 120°C for 24h. The dried activated carbon was placed in a tube furnace, and nitrogen gas was introduced into the furnace at 5 °C min -1 The rate was raised to 900 ° C for 2 h to obtain the required activated carbon. Dissolve sodium silicate in DMF and add deionized water to make up to 0.9g / ml, mix with 0.1g / ml chloroplatinic acid solution, stir at 70°C for 6h, and ultrasonicate at 60°C for 1h to obtain highly dispersed platinum solution. Weigh the above 1g of activated carbon and lay ...

Embodiment 2

[0031] Weigh 50ml of 20wt% nitric acid solution, soak 6g of activated carbon in the nitric acid solution by slowly adding dropwise while stirring with a magnetic stirrer, and slowly heat to 80°C for 10h. After cooling to room temperature, wash with deionized water until the filtrate is neutral. Weigh 0.06 g of thiourea solid, 5 g of nitric acid-treated activated carbon, and mix with 30 ml of deionized water. After mixing, they are ultrasonically treated at 40° C. for 0.5 h, and then vacuum-dried at 120° C. for 24 h. The dried activated carbon was placed in a tube furnace, and nitrogen gas was introduced into the furnace at 5 °C min -1 The rate was raised to 900 ° C for 2 h to obtain the required activated carbon. Dissolve sodium silicate in DMF and add deionized water to make up to 0.9g / ml, mix with 0.1g / ml chloroplatinic acid solution, stir at 70°C for 6h, and ultrasonicate at 60°C for 1h to obtain highly dispersed platinum solution. Weigh the above 1g of activated carbon ...

Embodiment 3

[0033] Weigh 50ml of 20wt% nitric acid solution, soak 6g of activated carbon in the nitric acid solution by slowly adding dropwise while stirring with a magnetic stirrer, and slowly heat to 80°C for 10h. After cooling to room temperature, wash with deionized water until the filtrate is neutral. Weigh 0.072g of thiourea solid, 5g of nitric acid-treated activated carbon, and mix with 30ml of deionized water. After mixing, they are ultrasonically treated at 40°C for 0.5h, and then vacuum-dried at 120°C for 24h. The dried activated carbon was placed in a tube furnace, and nitrogen gas was introduced into the furnace at 5 °C min -1 The rate was raised to 900 ° C for 2 h to obtain the required activated carbon. Dissolve sodium silicate in DMF and add deionized water to make up to 0.9g / ml, mix with 0.1g / ml chloroplatinic acid solution, stir at 70°C for 6h, and ultrasonicate at 60°C for 1h to obtain highly dispersed platinum solution. Weigh the above 1g of activated carbon and lay ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com